High-density high-strength pressure crack proppant

A fracturing proppant and high-strength technology, which is applied in the fields of ultra-deep gas wells and high closure pressure ultra-deep oil wells, can solve the problems of not being able to meet the needs of solid ceramsite proppants, achieve high compressive strength, improve conductivity, Good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

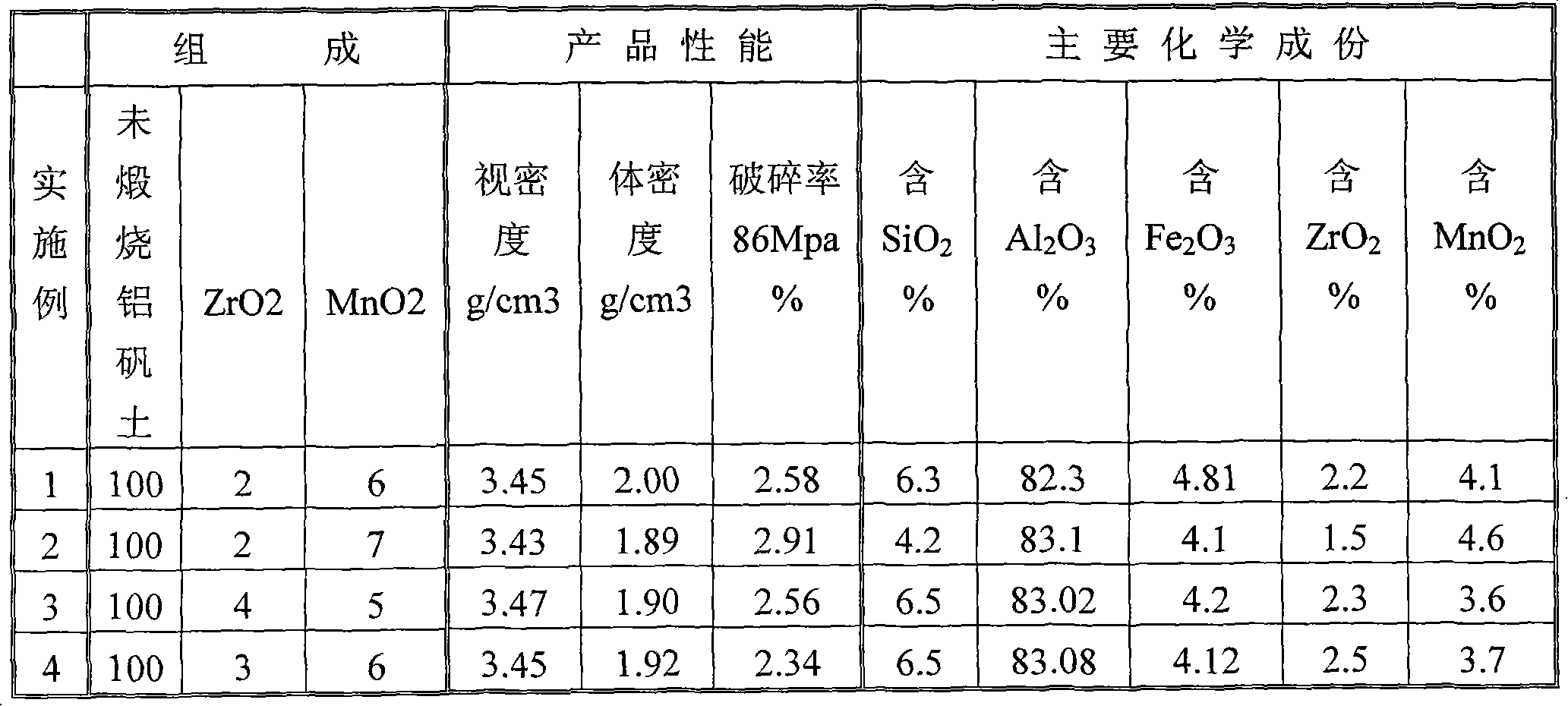

[0025]Example: According to the existing method of preparing proppant, the materials are selected, crushed, and mixed according to the ratio, and water is added in batches and pellets are added in batches in the pelletizing machine to reach the required particle size range standard and enter the rotary kiln for high-temperature firing. After granulation, roundness: 0.9; sphericity: 0.9, 20 / 40 mesh ceramsite proppant.

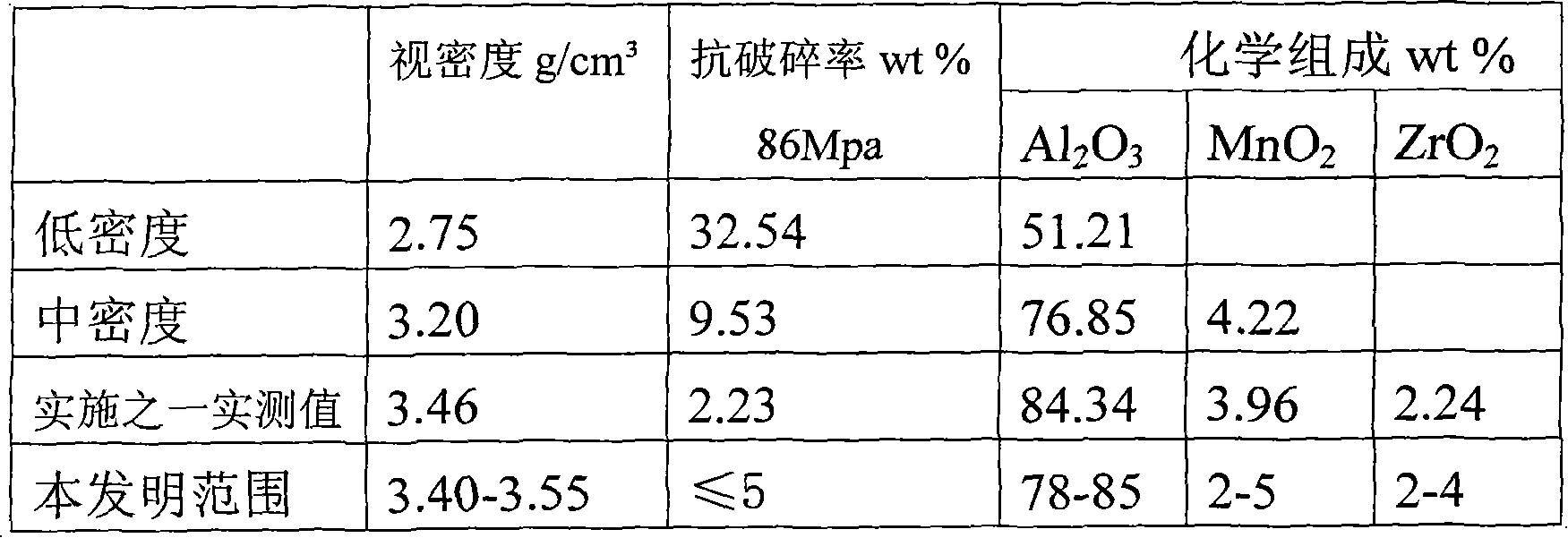

[0026] Example ratio table (parts by weight)

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com