Environment-friendly and bio-available green fracturing fluid system

An environmentally friendly, fracturing fluid technology, applied in the field of fracturing systems, can solve the problems of non-biological repair, harmful and toxic biomass, and difficult microbial biodegradation or reuse, so as to reduce equipment construction loss, save energy, and reduce construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

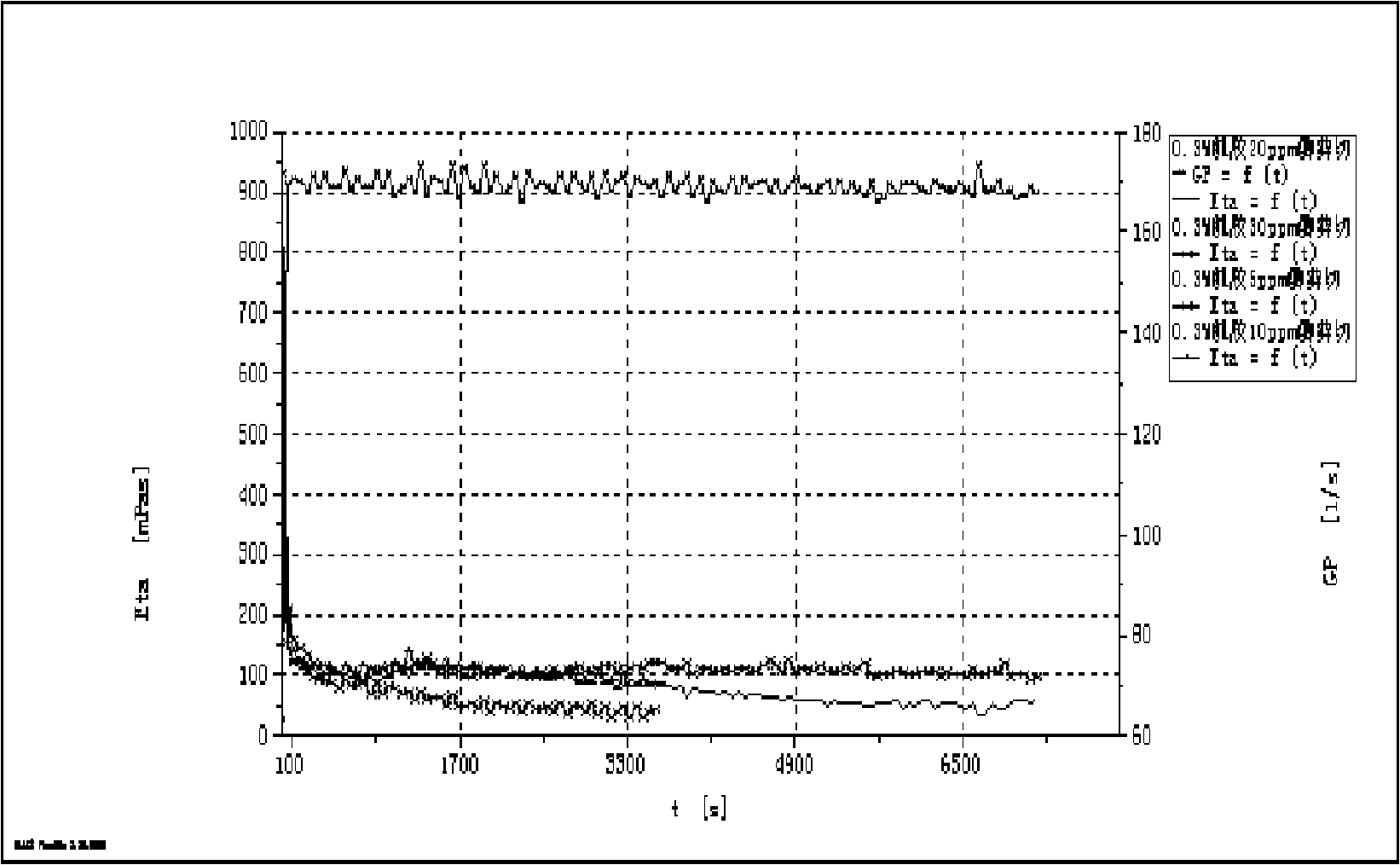

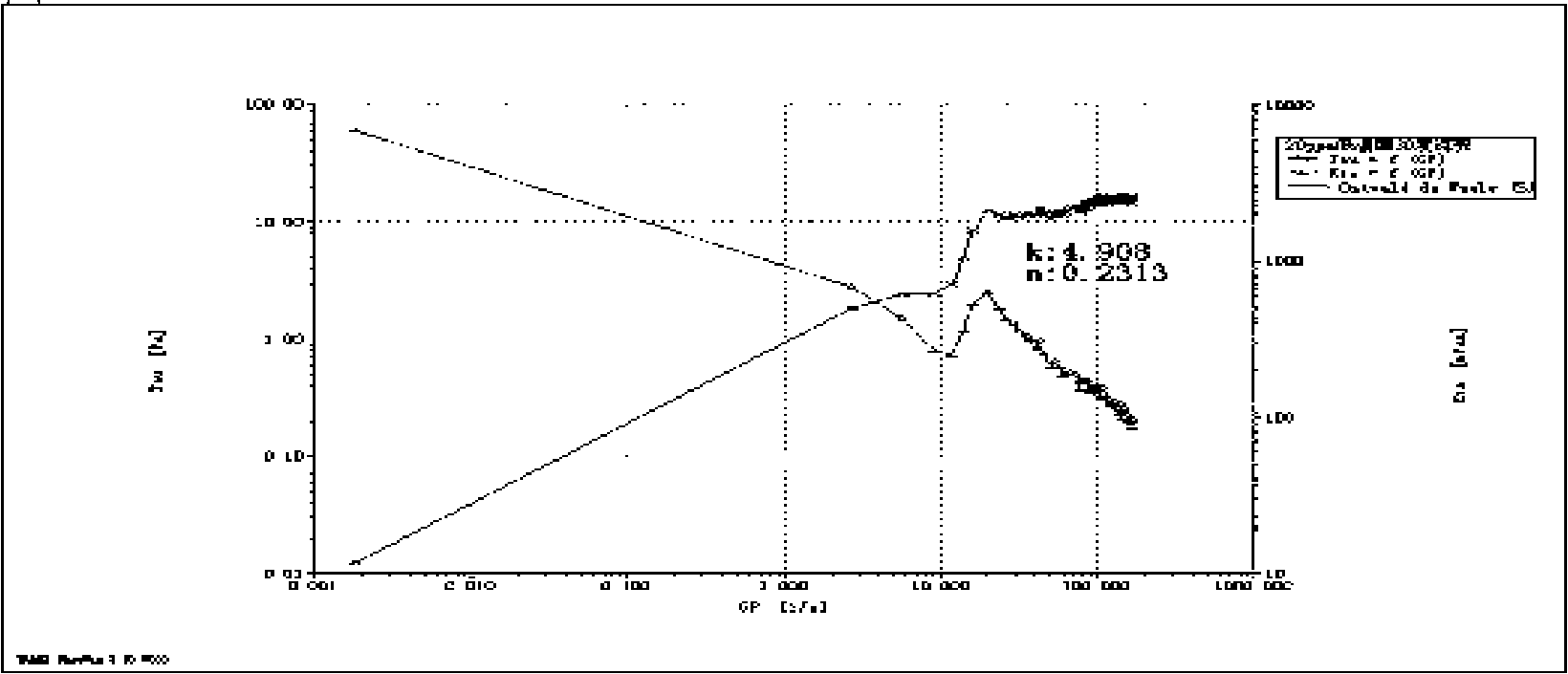

[0039] Rheology experiment: test the cross-linked jelly composed of the following formula:

[0040] Formula of fracturing system base fluid (based on cross-linking ratio of 100:5)

[0041] Additive Name Weight Amount (%)

[0042] Hydroxypropyl Guar Gum 0.30

[0043] Biological drainage aid (rhamnolipid) 0.025

[0044] Biological fungicide (surfactin) 0.002

[0045] Clay stabilizer (KCl) 1.00

[0046] Fracturing fluid optimizer (phosphate) 0.30

[0047] 1.0% crosslinking agent (borax aqueous solution) 4.80

[0048] In the above formula, the phosphate uses a self-made nitrogen and phosphorus source, and its composition is 1.60mol% KH 2 PO 4 , 0.70mol%K 2 HPO 4 , 0.32mol% (NH 4 ) 2 HPO 4 , the rest is water, and the pH is adjusted to 7-9.

[0049] Prepare the base liquid according to the formula, dilute the enzyme gel breaker (alkali-resistant and salt-resistant β-galactomannanase) 100 times with pure water, add a certain amount to the above-mentioned base liquid to ...

Embodiment 2

[0051] The enzyme gel breaking experiment used the base fluid prepared in Example 1, added 0.3% fracturing fluid optimizer, diluted the enzyme solution 100 times with pure water, so that the final concentration of the enzyme in the fracturing fluid was 20ppm, and then added 1.0% borax Cross-linking (cross-linking ratio 100:5), after 30s, it will form a hanging vegetable jelly. Put the cross-linked jelly into a jar, place it in a water bath at 45°C and let it stand for a gel breaking reaction. Samples were taken and analyzed every half an hour. The results showed that the viscosity of the fracturing fluid dropped to 3mPa·s in 2.0 hours.

Embodiment 3

[0053] Preparation of fracturing optimization agent: 130 grams of potassium hydroxide and 215 grams of ammonia water (concentration 28%) were mixed at room temperature, and then 30 grams of glacial acetic acid and 125 grams of phosphoric acid were mixed to prepare acid-base solutions respectively. Quickly add the lye through the dropping funnel into the three-necked bottle containing the acid solution with a condenser tube. During the feeding process, a violent exothermic reaction occurs. After cooling, it will contain KH 2 PO 4 , K 2 HPO4, NH 4 h 2 PO 4 and (NH 4 ) 2 HPO 4 fracturing optimizer solution. It can be directly used to prepare base fluid for fracturing or added to cross-linked jelly together with biological enzyme gel breaker for gel breaking reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com