Plastic liner protruding-type socket steel ring concrete top tube

A technology of socket steel ring and concrete pipe, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipes, etc., can solve the problems of high transmission power requirements, affecting the quality of the process engineering, poor impermeability, etc., to improve the engineering quality , The effect of improving economic efficiency and good impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

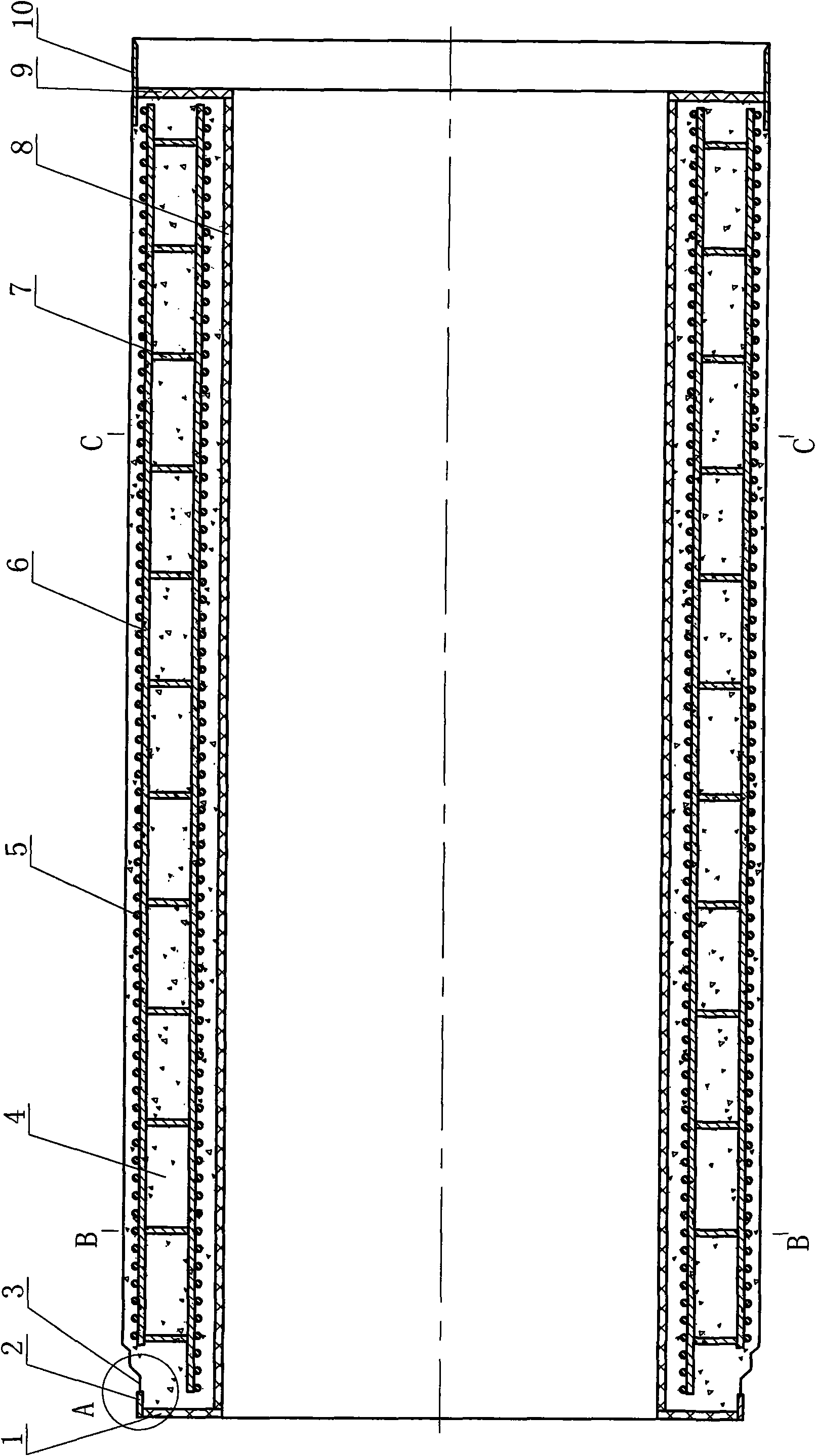

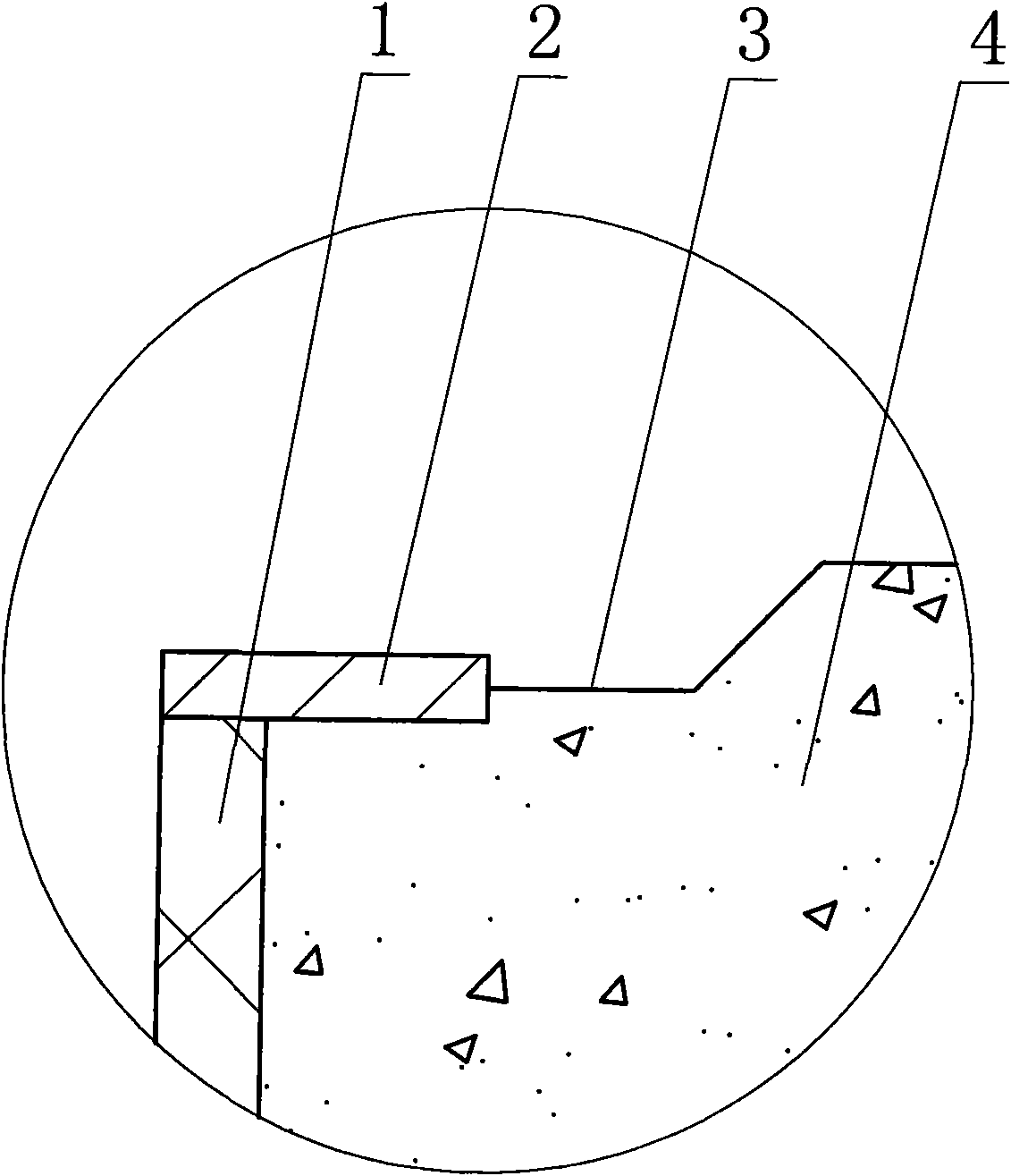

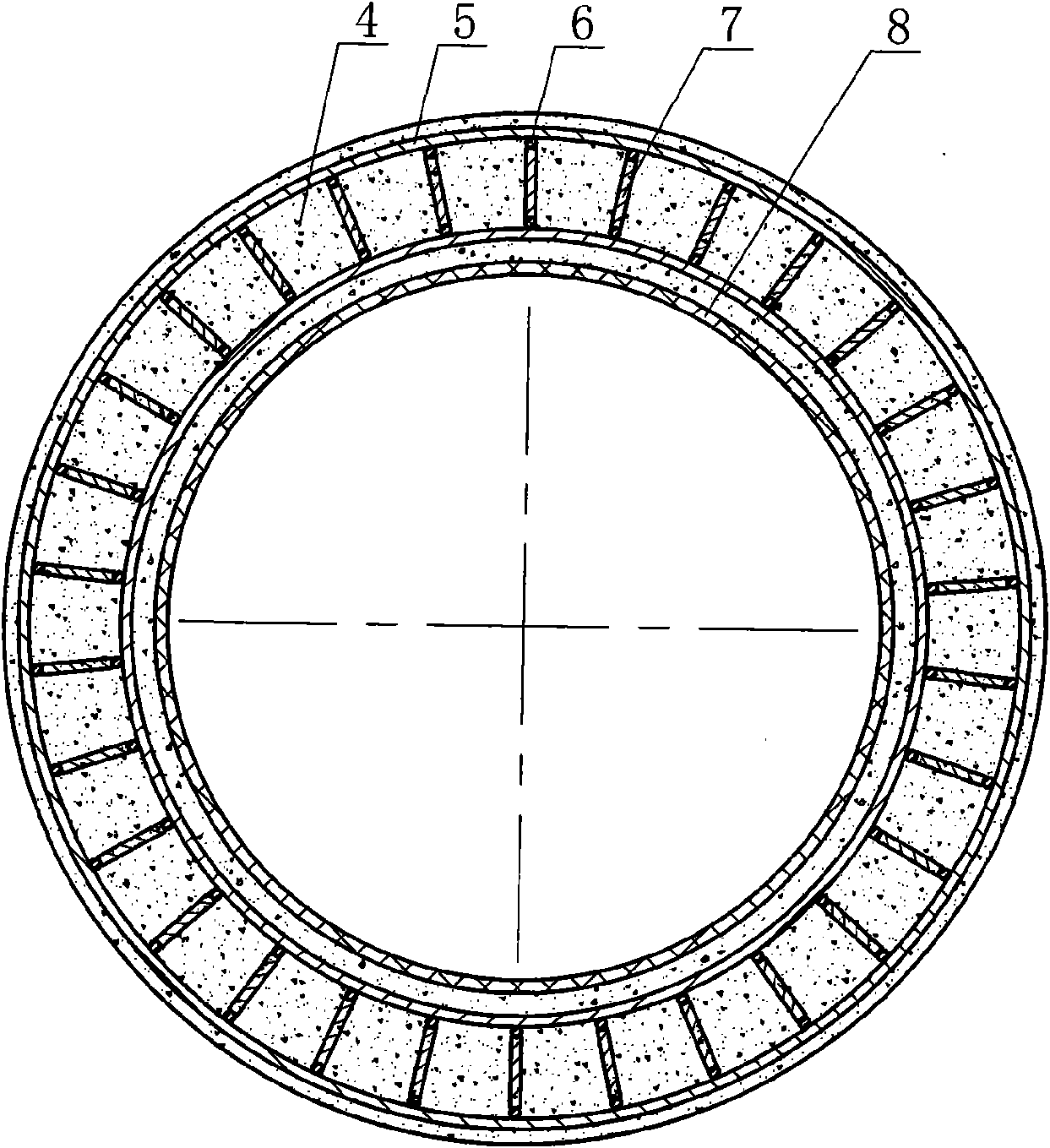

[0021] The plastic-lined protruding socket steel ring concrete jacking pipe is composed of a steel socket 10, a cylindrical steel skeleton pipe cage and a concrete pipe core 4. The steel socket is fixed on one end of the concrete pipe core, and the cylindrical steel skeleton The pipe cage is coaxially embedded in the concrete pipe core. The cylindrical steel skeleton pipe cage is composed of two coaxial cylindrical steel cages welded by the circumferential steel bars 5 and the longitudinal steel bars 6 and welded coaxially through the vertical bars 7. Formed cylindrical steel bar skeleton pipe cage form, (as shown in the accompanying drawing of this embodiment), this cylindrical steel bar skeleton also can be the cylindrical steel bar cage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com