Device for laying and fixing pipes for various circuits, domestic or industrial

a technology for fixing devices and pipes, applied in the direction of vertical ducts, pipes, electrical equipment, etc., can solve the problems of unsatisfactory aesthetics and unsuitable laying of electrical conductor ducts, and achieve the effect of reducing laying time and cost and simplifying the pipe installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

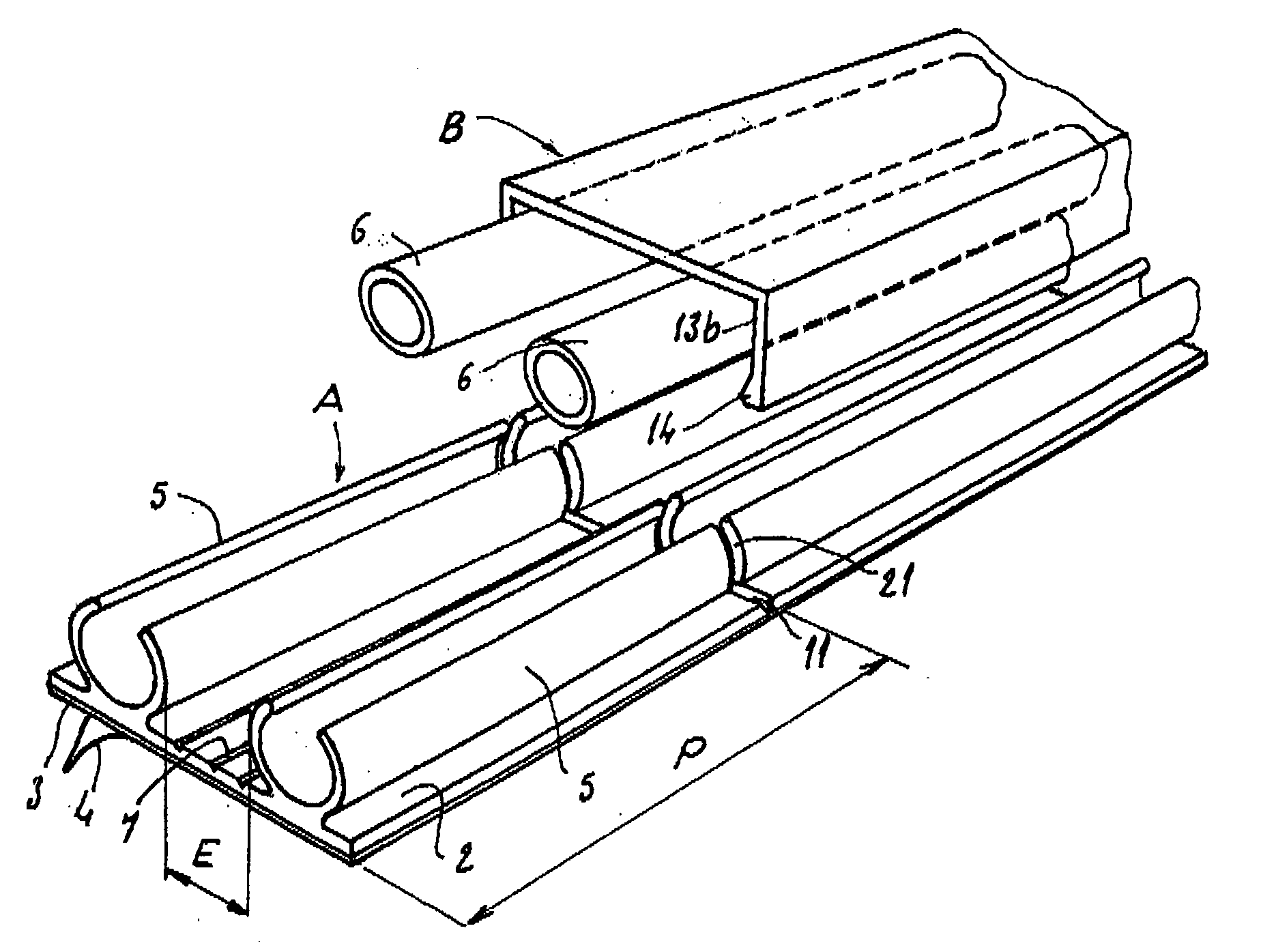

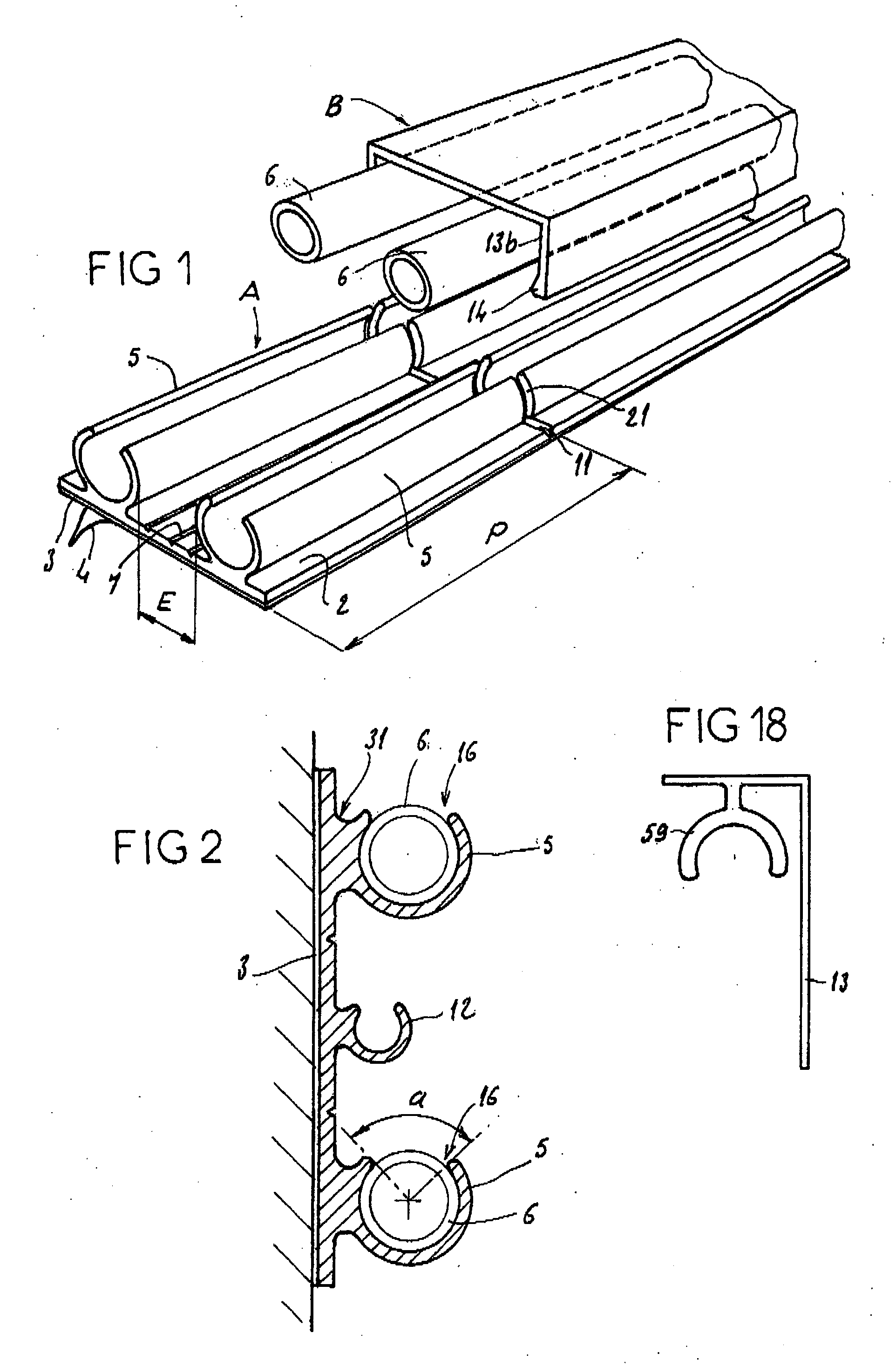

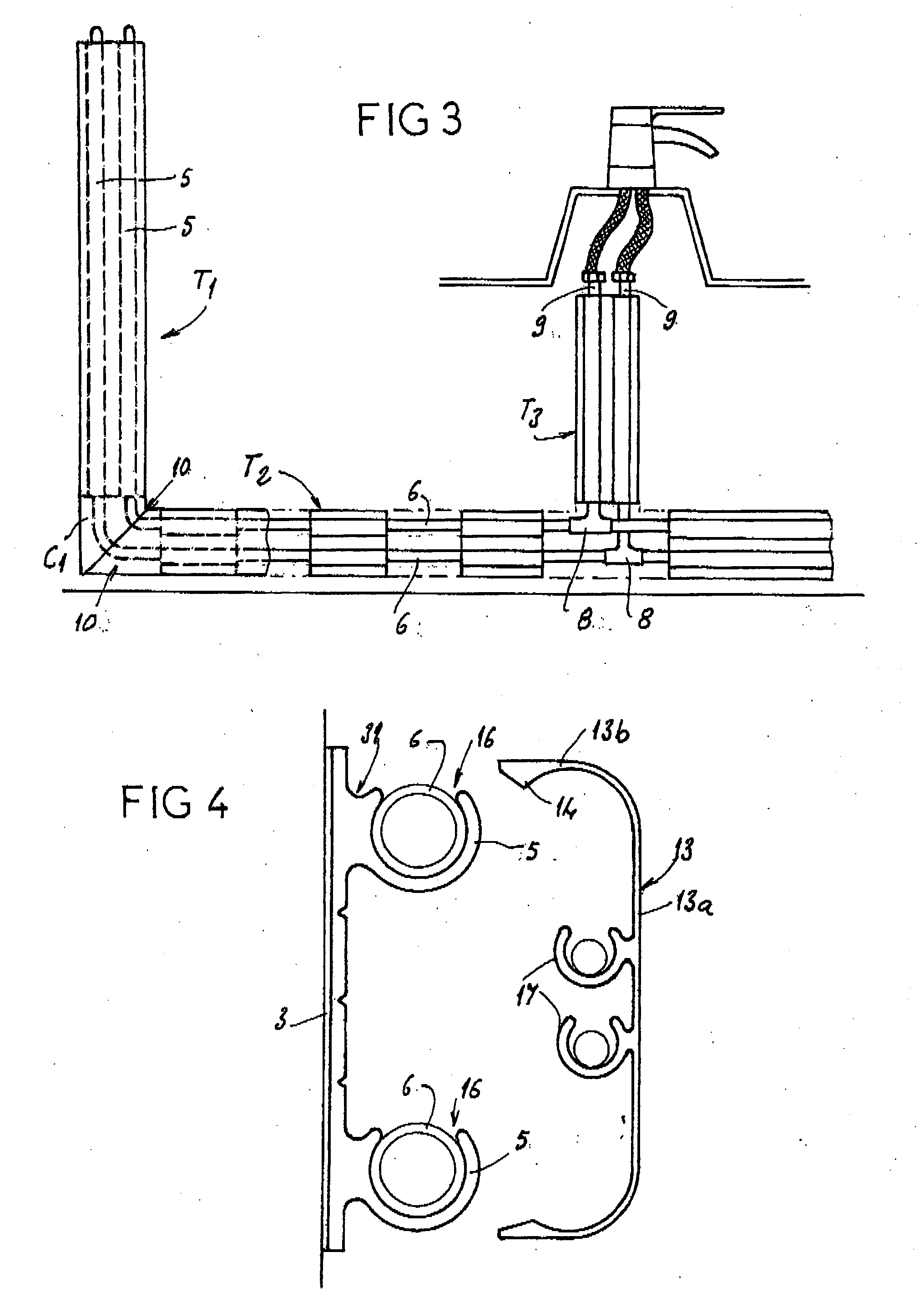

[0025] In FIG. 1, the reference A denotes a semirigid plastic profile comprising a mounting plate 2, on the back of which is a layer of adhesive 3 protected by a peel-off film 4. Projecting from the front of the mounting plate 2 are two open C-section gutters 5 whose internal dimension is appropriate for the pipes 6 with which these gutters are intended to engage. The two gutters are separated by a space E equal to or greater than the usual spacing of the pipes of the network in question.

[0026] In this space, the mounting plate 2 comprises one or more breakable longitudinal lines 7 consisting of a reduction in the thickness of its component material, and / or consisting of precuts (not shown). It also comprises breakable transverse lines 11 that are also formed by a thinning of the material or by a precut, and coincide with slots 21 running through the gutters 5 all the way to the mounting plate 2. In practice the spacing P from each breakable line and slit 21 to the next is about 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com