Prefabricated reinforced concrete component with grooves and manufacturing method thereof

A technology of reinforced concrete and a manufacturing method, which is applied to building components, structural elements, manufacturing tools, etc., to achieve the effects of convenient transportation and installation, resource saving and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 is a prefabricated reinforced concrete slab member with grooves, such as figure 1 , figure 2 As shown, the longitudinal edge of the plate 11 is arranged with transverse grooves 12, which are arranged alternately with the protrusions 13; the plate 11 has several longitudinal holes 14, and the holes near the longitudinal edge intersect with the transverse grooves 12; the plate 11 is provided with mounting rings 15 . When prefabricated reinforced concrete slab members are used as walls, the length is generally taken as the height of the building, the width is generally taken as a modulus of 300, and the thickness is equal to the thickness of the wall.

[0043] The preparation method of embodiment 1 comprises the following steps:

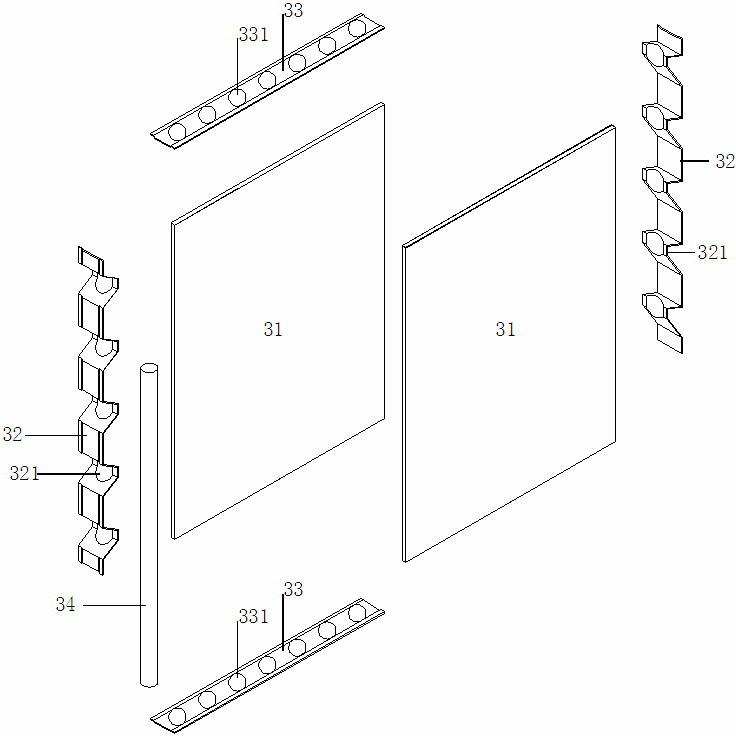

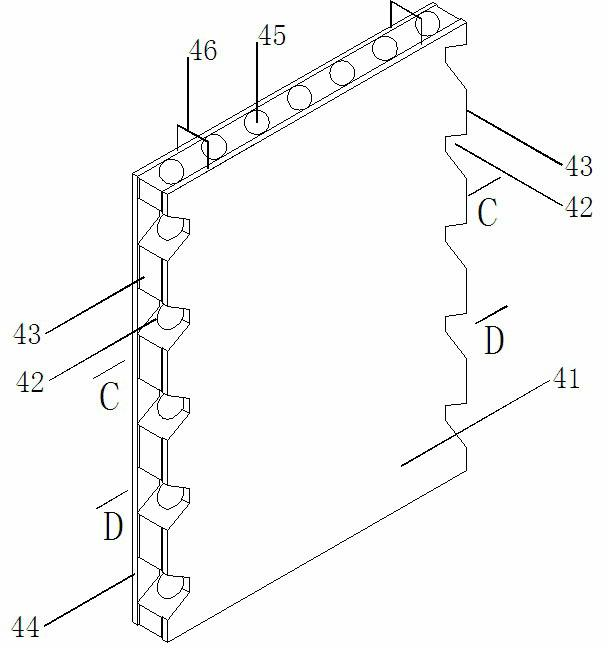

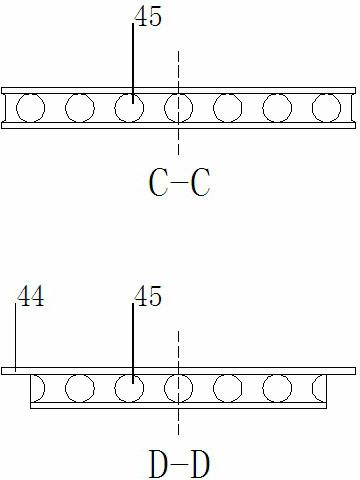

[0044] 1) Arrange the flat bottom form 31, two side forms 32 and two top forms 33 on the production site according to the size of the prefabricated components, such as image 3 , arranging reinforcement cages and suspension rings...

Embodiment 2

[0050] Embodiment 2 is a prefabricated reinforced concrete T-shaped wall column member with grooves, such as Figure 8 As shown, the longitudinal edge of the T-shaped wall column member 81 is arranged with transverse grooves 82 (at least one longitudinal edge is arranged with transverse grooves), which are arranged alternately with the protrusions 83 on the longitudinal edges; the T-shaped wall column member 81 has several longitudinal holes 84, the hole near the longitudinal edge intersects with the transverse groove 82; the T-shaped wall column member 81 is provided with an installation ring 85. In practical application, the three limbs of the T-shaped wall column adopt the limb lengths that meet the requirements of the building structure. The length of the T-shaped wall column member is generally taken as the story height of the building, and the thickness is generally equal to that of the wall.

[0051] The preparation method of embodiment 2 comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com