Automatic packaging device for fertilizer production and processing

An automatic packaging and equipment technology, applied in the direction of packaging, etc., can solve the problems that the sealing of the packaging bag cannot be guaranteed, the opening of the packaging bag cannot be uniform and flat, and the quality of the sealing of the packaging bag is affected, so as to achieve integrated production and save manpower , Improve the effect of sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

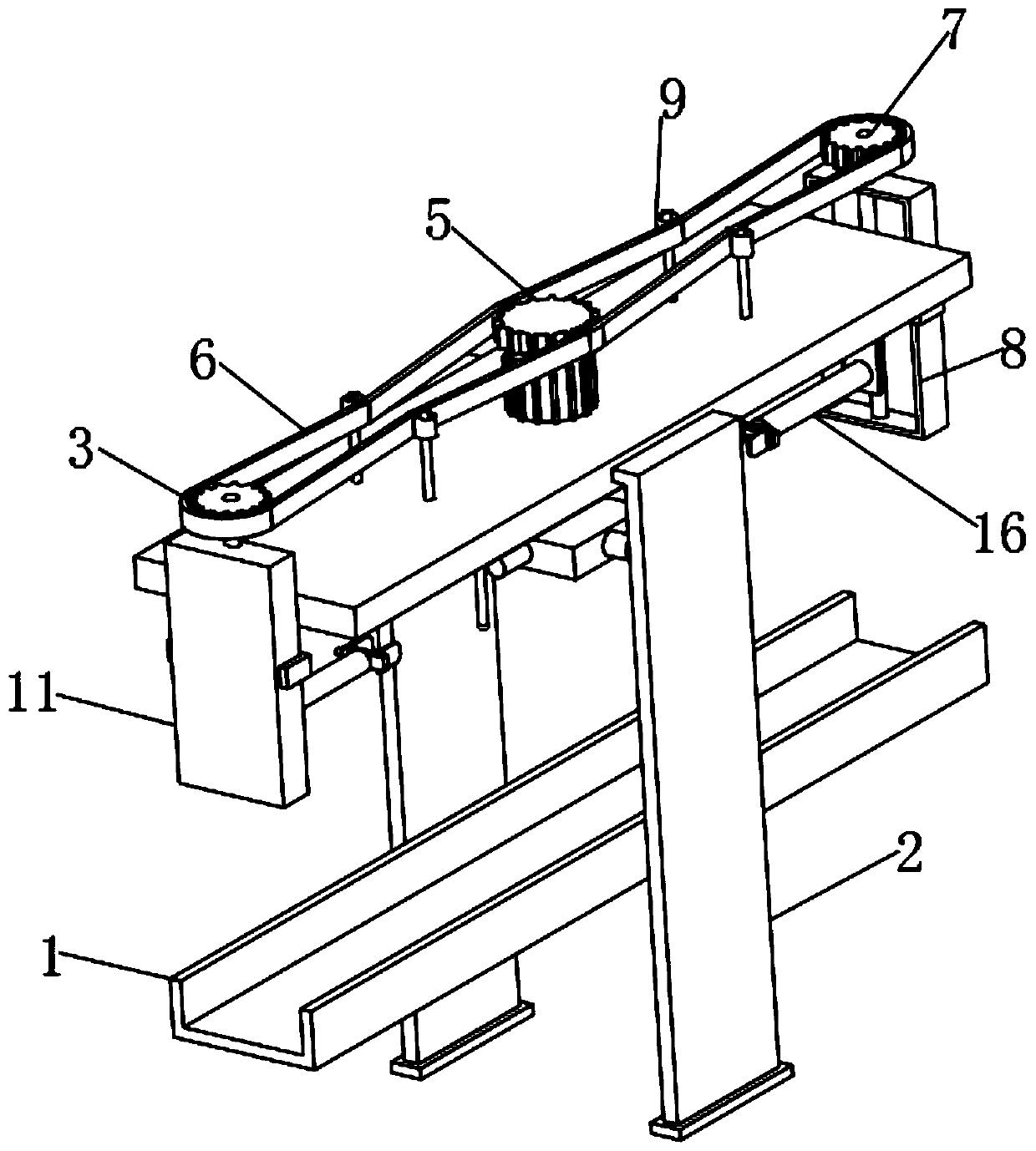

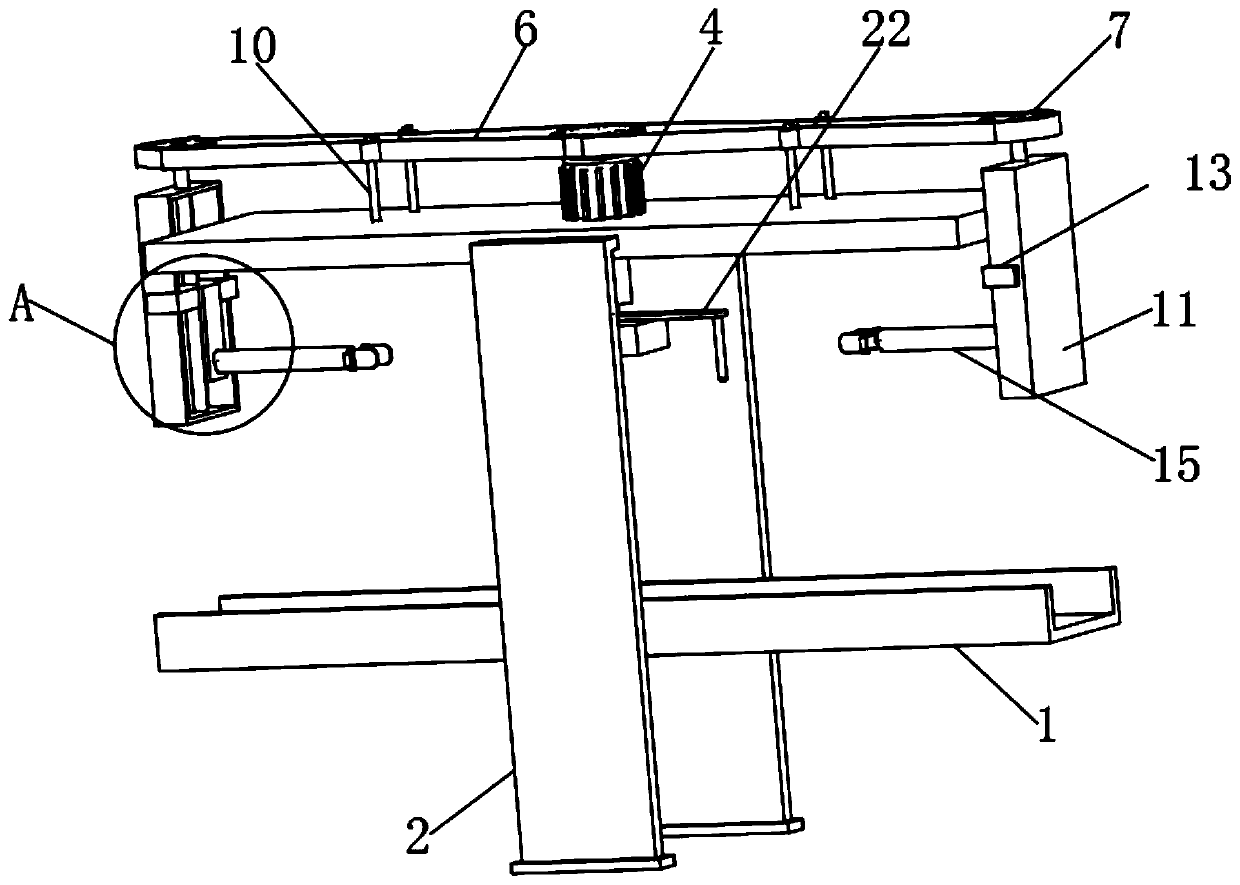

[0027] Specific implementation method: when the packaging bag containing the fertilizer moves to the bottom of the support frame 2 on the conveying platform 1, and the infrared sensor 28 senses the packaging bag, the drive motor 4 runs at this time, so that the driving gear 5 passes through the gear belt 6 Drive the two driven gears 7 to rotate, and because the two driven gears 7 are fixedly connected to the outside of one end of the screw mandrel 12, the screw mandrel 12 is relatively rotated inside the supporting shell 11. The driving force when the rod 12 rotates, and at the same time the limiting force on the support shell 11 , and then the driving sleeve moves vertically downward on the support shell 11 .

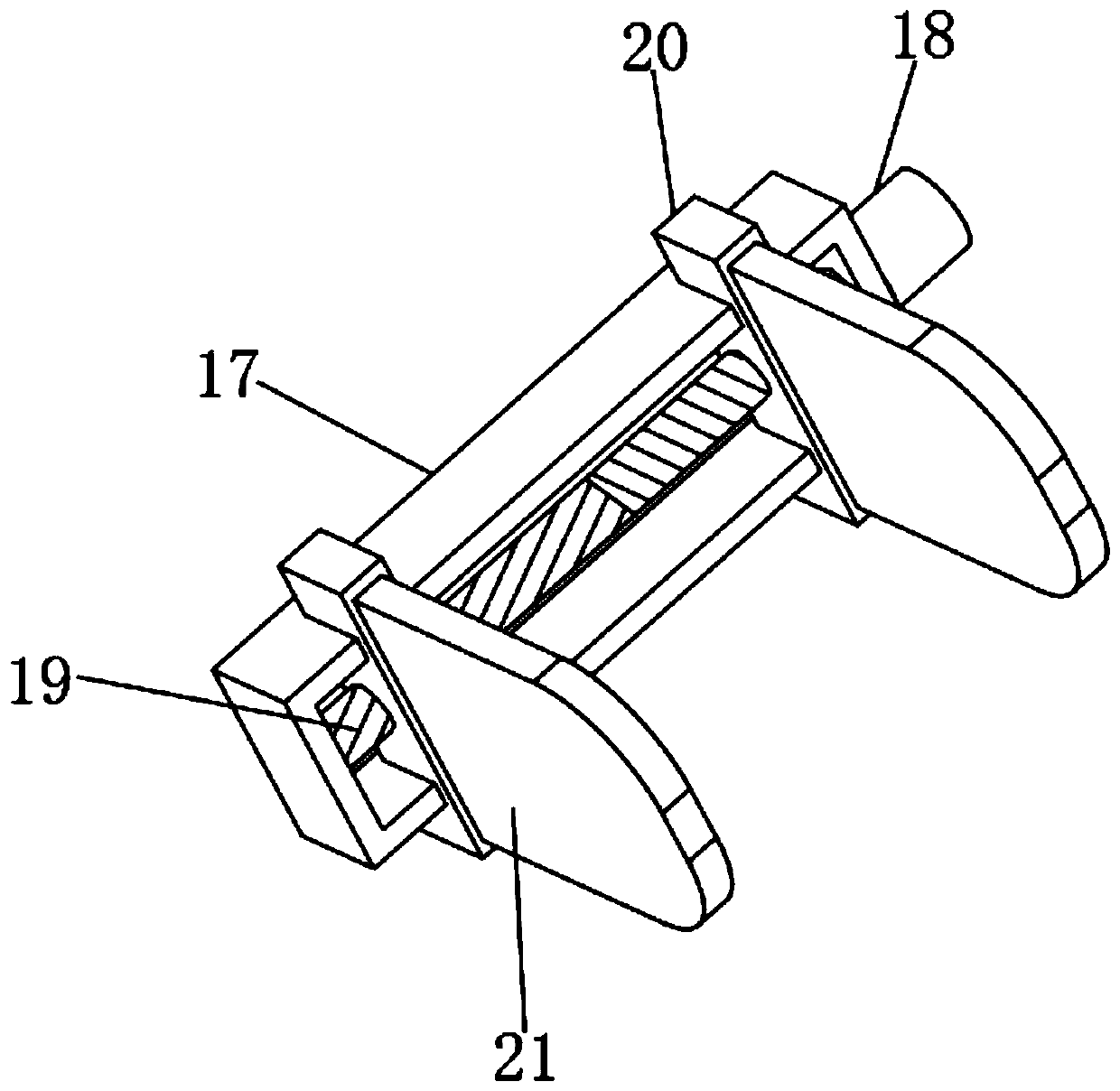

[0028] The leveling device includes a connecting plate 14, a first electric push rod 15 and a tension member 16, one side of the top end of the connecting plate 14 is fixedly connected with the moving sleeve 13, and the bottom end of the connecting plate 14 is away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com