Equipment for automatically processing molding bean curd packed in box

A kind of processing equipment and fully automatic technology, which is applied in the field of fully automatic processing equipment for forming boxed tofu, can solve the problems of unintuitive operation, low reliability, mechanical system impact, etc., and achieve perfect protection function, improve production efficiency and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

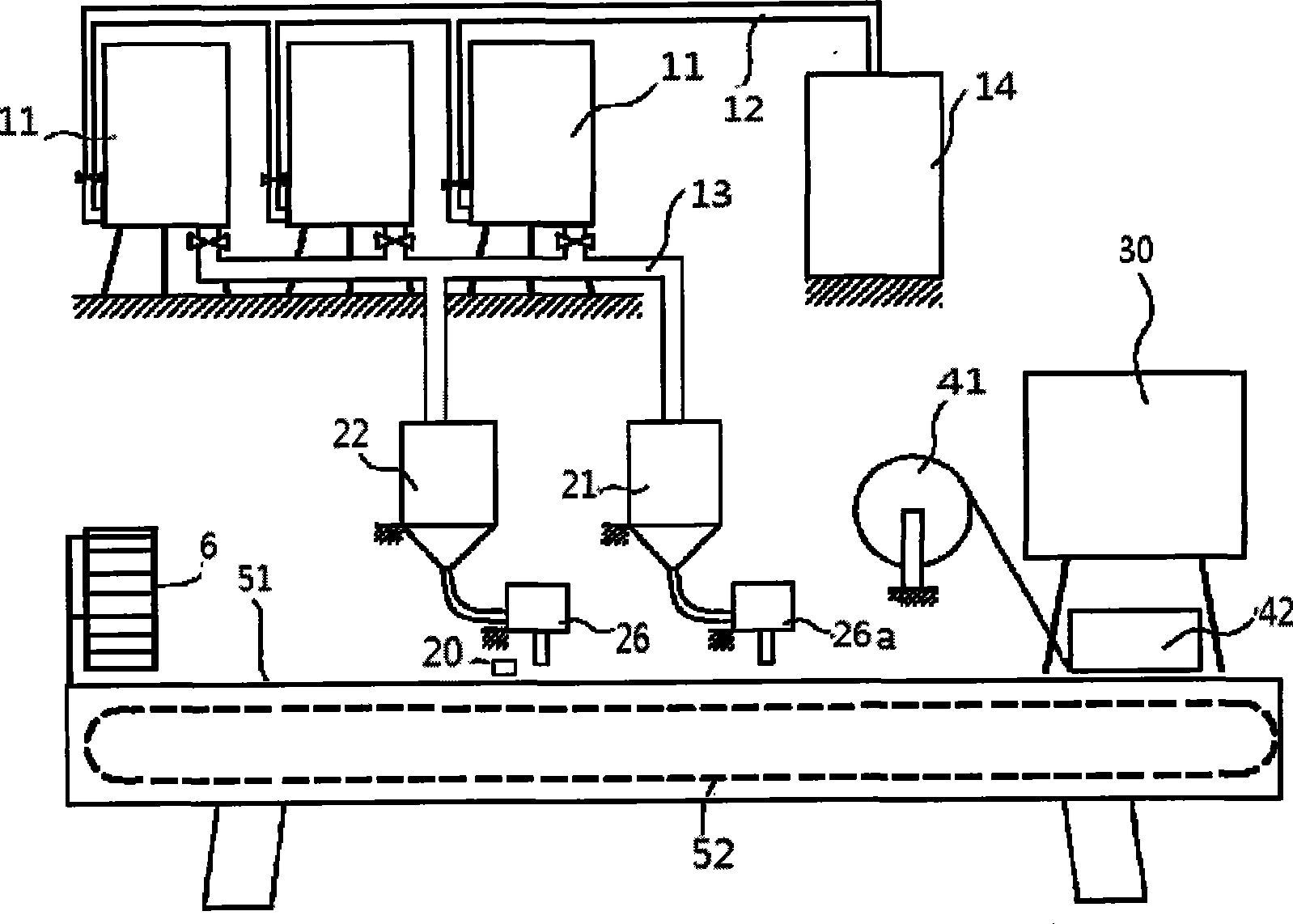

[0040] see figure 1, the present invention is provided with three cooking tanks 11 at a relatively high position, and the soybean milk in the cooking tanks 11 is prepared in a certain proportion by adding water from soybean flour and additives, and mixed evenly in a homogenizer, and then using the cooking tanks 11 The steam pipeline 12 provided inside is heated, and the steam is generated by the electric steam boiler 14. The pulp cooking tank 11 is connected in series through the slurry pipeline 13, and the soybean milk boiled in the pulp cooking tank 11 flows through the slurry pipeline 13 and is set at a lower In the slurry hopper 21 at the position, an electric heating device for heat preservation is provided in the slurry hopper 21 to mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com