Temporary storage and feeding method and device and computer readable storage medium

A feeding device and caching technology, which is applied to computer parts, computing, transportation and packaging, etc., can solve problems such as low work efficiency, difficulty in effective scanning, and large labor requirements, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a buffering and feeding method for parcel flow distribution.

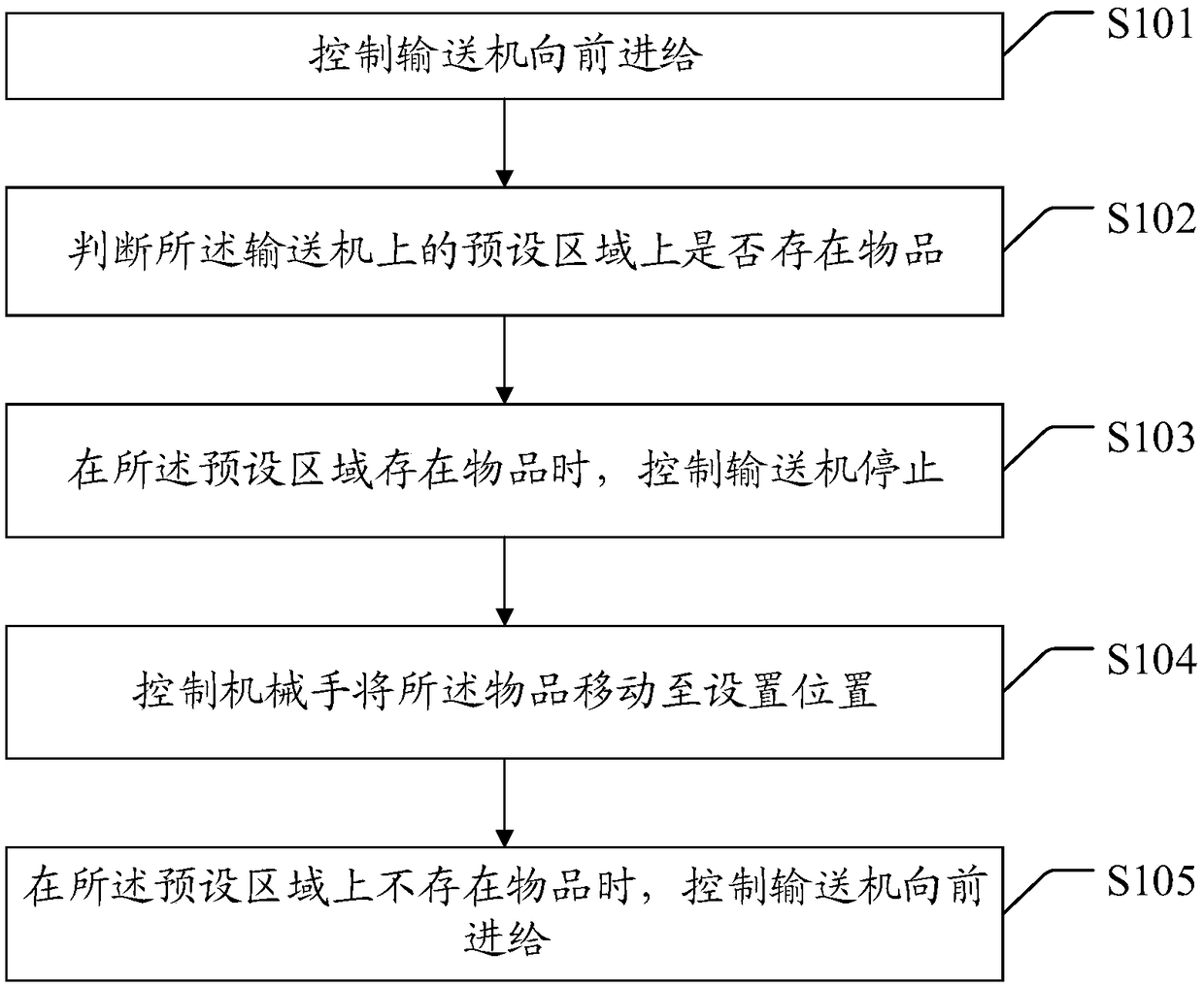

[0052] Please see figure 1 , the cache and feed methods include:

[0053] Step S101, controlling the conveyor to feed forward;

[0054] Step S102, judging whether there are articles in the preset area on the conveyor;

[0055] Step S103, when there are articles in the preset area, control the conveyor to stop;

[0056] Step S104, controlling the manipulator to move the item to the set position;

[0057] Step S105, when there is no article in the preset area, control the conveyor to move forward.

[0058] In this embodiment, the conveyor is first controlled to feed forward. Among them, in the traditional conveyor control scheme, the scheme of continuous feeding is usually adopted. And in the present embodiment, what adopted is that the conveyor is controlled to advance. As for the condition of whether the conveyor is moving forward, as described in the subsequent steps, it can ...

Embodiment 2

[0073] This embodiment provides a caching and feeding method. This embodiment is based on the foregoing embodiments, and the steps therein are described in detail. details as follows:

[0074] Please see Figure 4 , the judging whether there is an item in the preset area includes:

[0075] Step S201, obtaining an image including a preset area on the conveyor captured by a photographing device;

[0076] Step S202, judging whether there is an item in the preset area according to the image.

[0077] Other steps in this embodiment are the same as those in the foregoing embodiments, and reference may be made to the foregoing embodiments for details, and details are not repeated here.

[0078] In this embodiment, after the conveyor runs, an image captured by the photographing device and including a preset area on the conveyor is obtained. Wherein, the shooting device is pre-installed on a fixed position, and the lens is aimed at the preset area of the conveyor, so as to take ...

Embodiment 3

[0082] This embodiment provides a caching and feeding method. This embodiment is based on the foregoing embodiments, and the steps therein are described in detail. details as follows:

[0083] Please see Figure 5 , the controlling the manipulator to move the item to the set position includes:

[0084] Step S301, obtaining an image including a preset area on the conveyor captured by a photographing device;

[0085] Step S302, identifying the category and location information of the item according to the image;

[0086] Step S303, obtaining the matching setting position of the item according to the classification information;

[0087] Step S304, controlling the manipulator to acquire the item according to the position information, and move the item to the set position.

[0088] Other steps in this embodiment are the same as those in the foregoing embodiments, and reference may be made to the foregoing embodiments for details, and details are not repeated here.

[0089] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com