Monocrystalline silicon growth furnace with high safety performance

A technology of safety performance and growth furnace, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as major safety hazards, achieve the effects of increasing service life, convenient cleaning, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

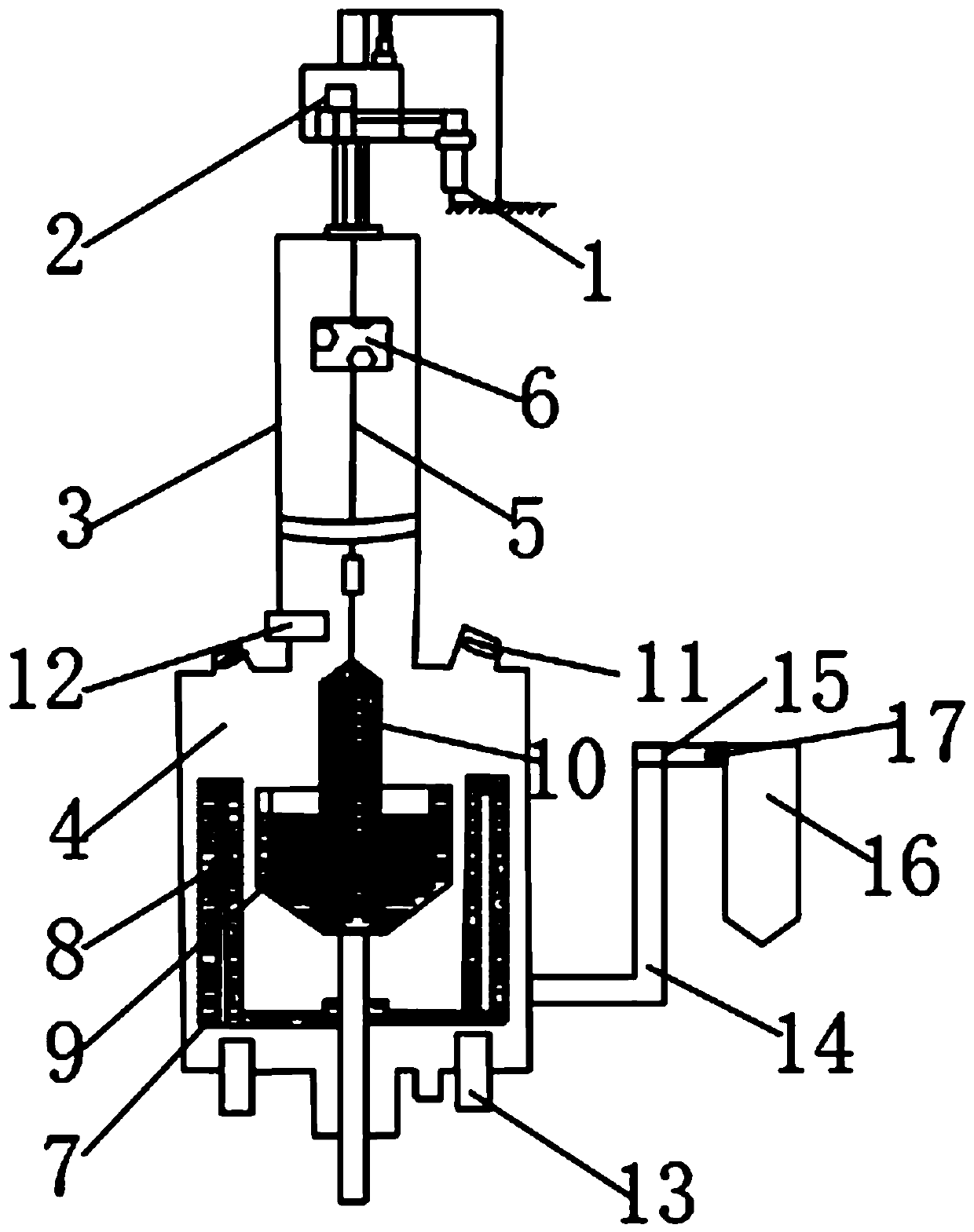

[0029] like Figure 1-4 As shown, a single crystal silicon growth furnace with high safety performance includes a growth furnace as a whole 1, and the growth furnace as a whole 1 includes a lifting and rotating system 2, an upper furnace cover 3 and a lower furnace body 4, and the pulling and rotating system 2 is located in the upper furnace The upper end of the cover 3, the upper furnace cover 3 is provided with a lifting rope 5, the upper end of the lifting rope 5 is connected with the lower end of the lifting rotation system 2, the lower end of the lifting rope 5 is connected with a single crystal rod 10, and the lower furnace body 4 includes a graphite heater 8 and a quartz crucible 9, the single crystal rod 10 is located in the quartz crucible 9, the outer surface of the quartz crucible 9 is provided with a graphite heater 8, the graphite heater 8 is provided with a heat preservation cover 7, and the lower furnace body 4 The lower end is provided with an air inlet 13 .

...

Embodiment 2

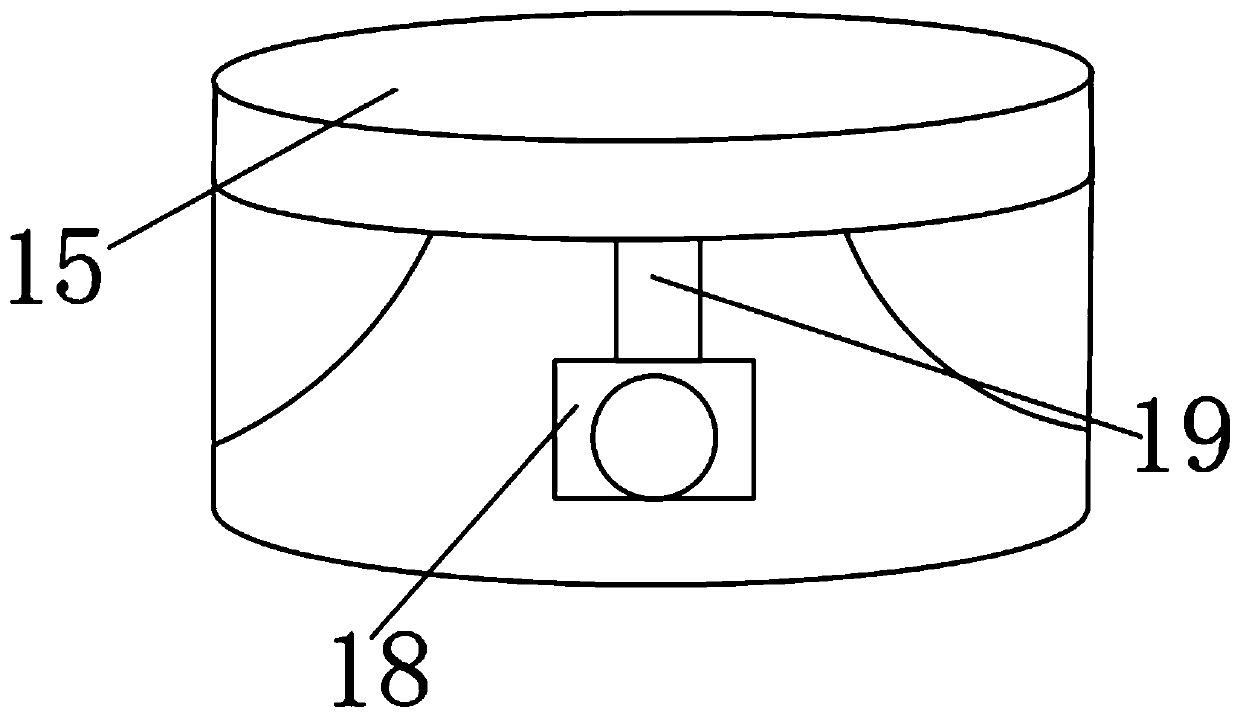

[0037] like figure 1 , Figure 5 , Image 6 As shown, a single crystal silicon growth furnace with high safety performance includes a growth furnace as a whole 1, and the growth furnace as a whole 1 includes a lifting and rotating system 2, an upper furnace cover 3 and a lower furnace body 4, and the pulling and rotating system 2 is located in the upper furnace The upper end of the cover 3, the upper furnace cover 3 is provided with a lifting rope 5, the upper end of the lifting rope 5 is connected with the lower end of the lifting rotation system 2, the lower end of the lifting rope 5 is connected with a single crystal rod 10, and the lower furnace body 4 includes a graphite heater 8 and a quartz crucible 9, the single crystal rod 10 is located in the quartz crucible 9, the outer surface of the quartz crucible 9 is provided with a graphite heater 8, the graphite heater 8 is provided with a heat preservation cover 7, and the lower furnace body 4 An air inlet 13 is provided a...

Embodiment 3

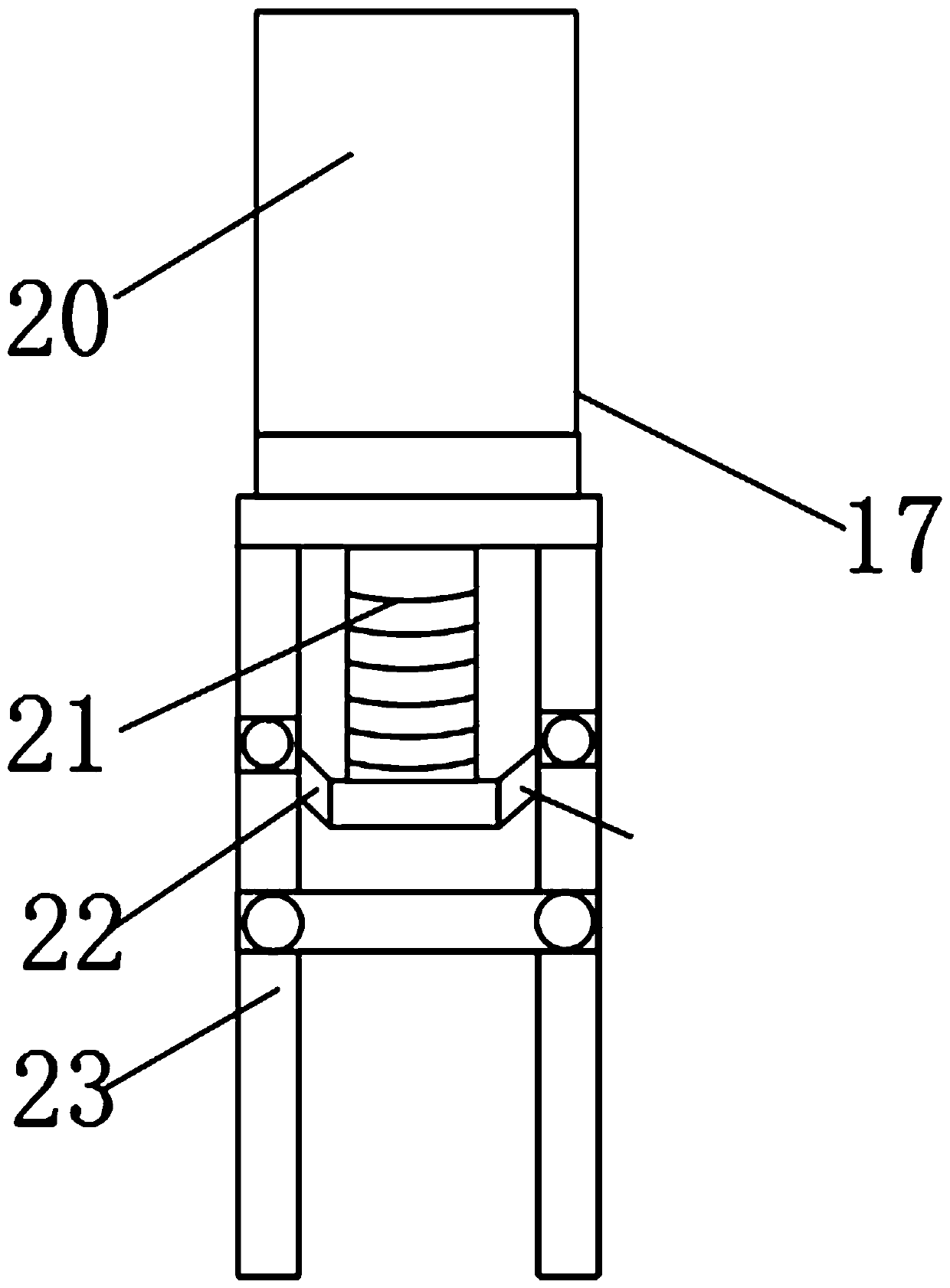

[0043] like figure 1 , Figure 7 As shown, a single crystal silicon growth furnace with high safety performance includes a growth furnace as a whole 1, and the growth furnace as a whole 1 includes a lifting and rotating system 2, an upper furnace cover 3 and a lower furnace body 4, and the pulling and rotating system 2 is located in the upper furnace The upper end of the cover 3, the upper furnace cover 3 is provided with a lifting rope 5, the upper end of the lifting rope 5 is connected with the lower end of the lifting rotation system 2, the lower end of the lifting rope 5 is connected with a single crystal rod 10, and the lower furnace body 4 includes a graphite heater 8 and a quartz crucible 9, the single crystal rod 10 is located in the quartz crucible 9, the outer surface of the quartz crucible 9 is provided with a graphite heater 8, the graphite heater 8 is provided with a heat preservation cover 7, and the lower furnace body 4 An air inlet 13 is provided at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com