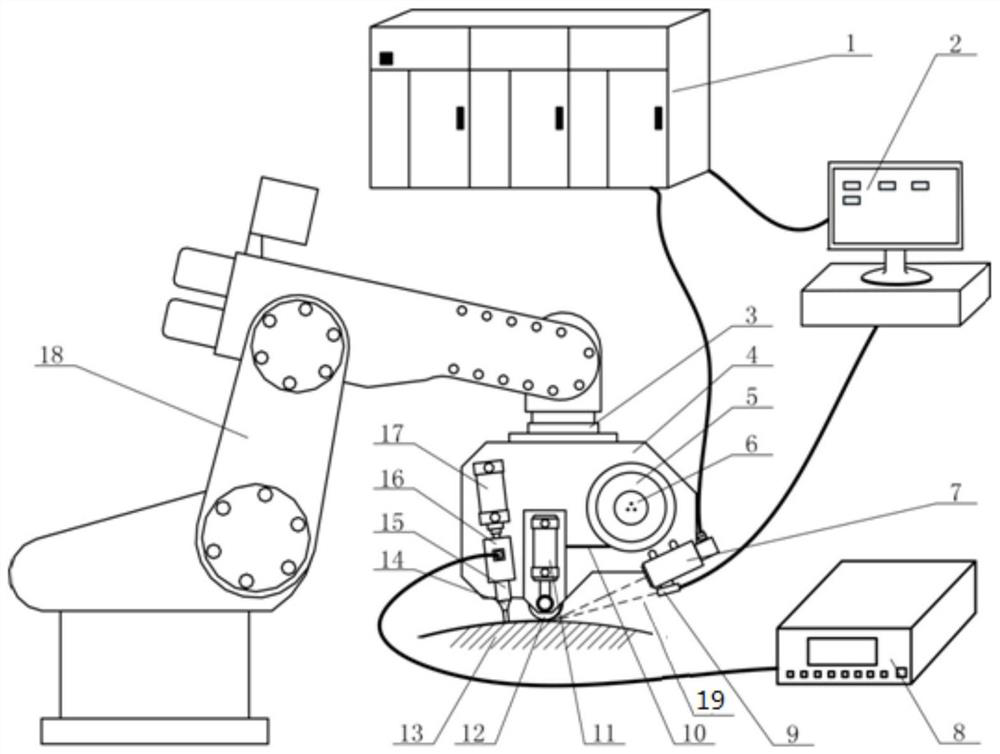

Thermoplastic composite material automatic laying device and method

A composite material and thermoplastic technology, applied in the field of thermoplastic composite material automatic laying device, can solve the problems of low connection strength, slow laying speed, difficult control of processing temperature, etc., to achieve accurate heating area, fast heating speed, and saving laying The effect of molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

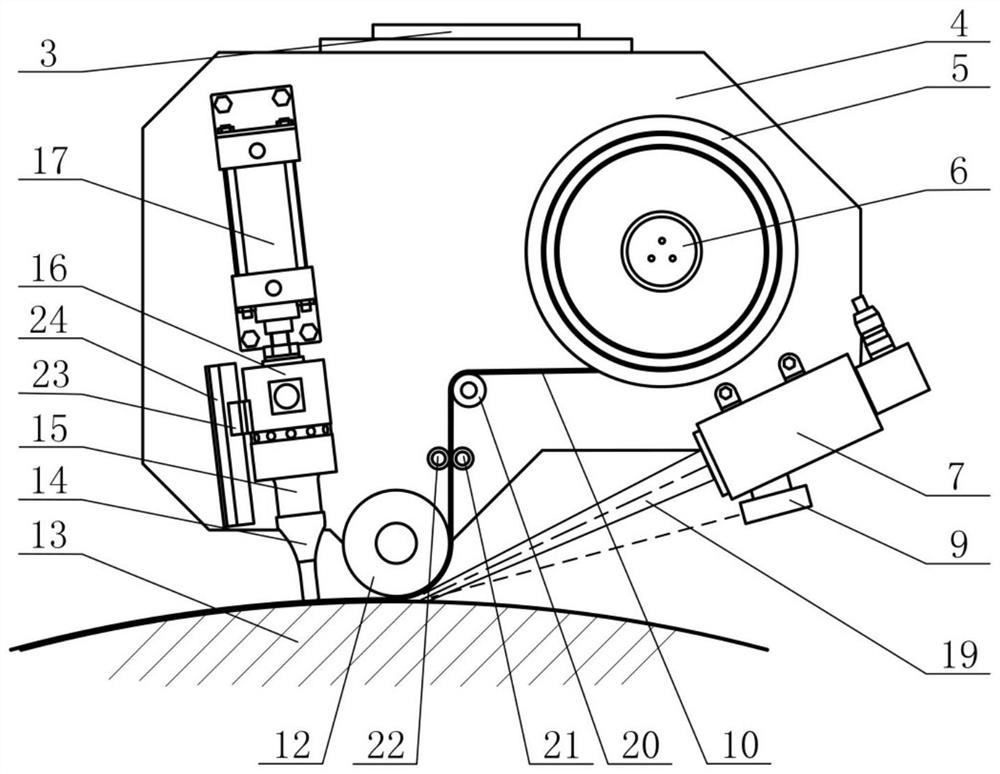

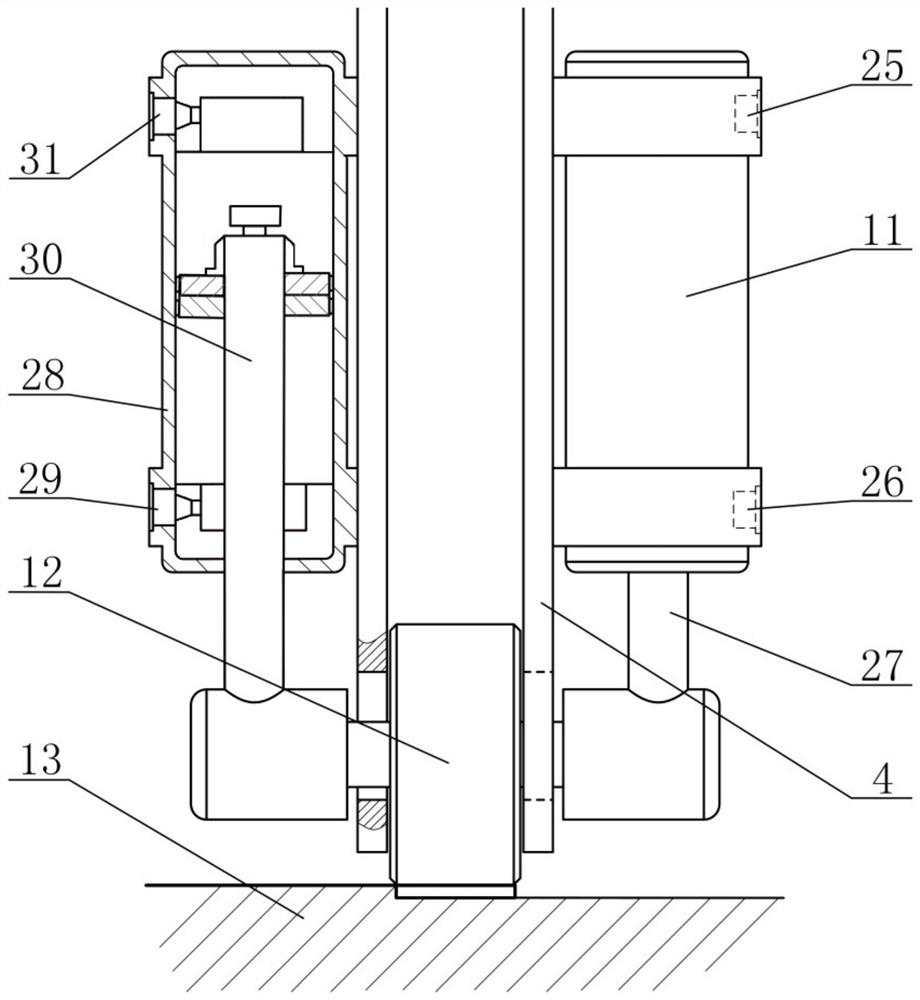

[0052] The automatic placement of the aramid / PA prepreg tape 10 with a size of 0.5mm×12mm using a composite material automatic placement device includes the following steps:

[0053] Step 1: The robot 18 pulls and installs the supporting plate 4 of the laying device, the laser welding device and the ultrasonic vibration device to the base material 13, and the aramid / PA prepreg tape 10 passes through the guide wheel 20, the main driving roller 21 and the auxiliary driving roller 22 The first air hole 25 and the fourth air hole 31 take in air, the second air hole 26 and the third air hole 29 exhaust, and the first piston rod 27 and the second piston rod 30 push the pressure roller 12 to make The aramid / PA prepreg tape 10 and the base material 13 are closely attached, and the pressure of the first pneumatic cylinder 11 and the third pneumatic cylinder 28 are adjusted to make the pressure of the pressure roller 12 to the aramid / PA prepreg tape 10 to be 1.0MPa At the same time, the si...

Embodiment 2

[0058] The basalt fiber and carbon fiber blend / PE prepreg tape 10 with a size of 0.4mm×10mm is automatically laid by a composite material automatic laying device, which specifically includes the following steps:

[0059] Step 1: The robot 18 pulls and installs the support plate 4 of the laying device, the laser welding device and the ultrasonic vibration device to the base material 13, and the basalt fiber and carbon fiber blend / PE prepreg tape 10 passes through the guide wheel 20, the main driving roller 21 and The auxiliary driving roller 22 is conveyed to the bottom of the pressurizing roller 12, the first air hole 25 and the fourth air hole 31 take in air, the second air hole 26 and the third air hole 29 exhaust, and the first piston rod 27 and the second piston rod 30 push and pressurize The roller 12 makes the basalt fiber and carbon fiber blend / PE prepreg tape 10 and the base material 13 closely fit, adjusts the pressure of the first pneumatic cylinder 11 and the third pneu...

Embodiment 3

[0064] Automatic laying of the glass fiber / PP prepreg tape 10 with a size of 0.3mm×15mm using a composite material automatic laying device includes the following steps:

[0065] Step 1: The robot 18 pulls and installs the support plate 4 of the laying device, the laser welding device and the ultrasonic vibration device to the substrate 13, and the glass fiber / PP prepreg tape 10 passes through the guide wheel 20, the main driving roller 21 and the auxiliary driving roller 22 The first air hole 25 and the fourth air hole 31 take in air, the second air hole 26 and the third air hole 29 exhaust, and the first piston rod 27 and the second piston rod 30 push the pressure roller 12 to make The glass fiber / PP prepreg tape 10 is closely attached to the base material 13, and the pressure of the first pneumatic cylinder 11 and the third pneumatic cylinder 28 is adjusted so that the pressure of the pressure roller 12 on the glass fiber / PP prepreg tape 10 is 0.8 MPa At the same time, the sixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com