Environment-friendly dust removal method

An environmentally friendly and thread technology, applied in the field of environmental protection and dust removal, can solve the problem of insufficient cleaning of thread gaps, and achieve the effect of solving detection difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

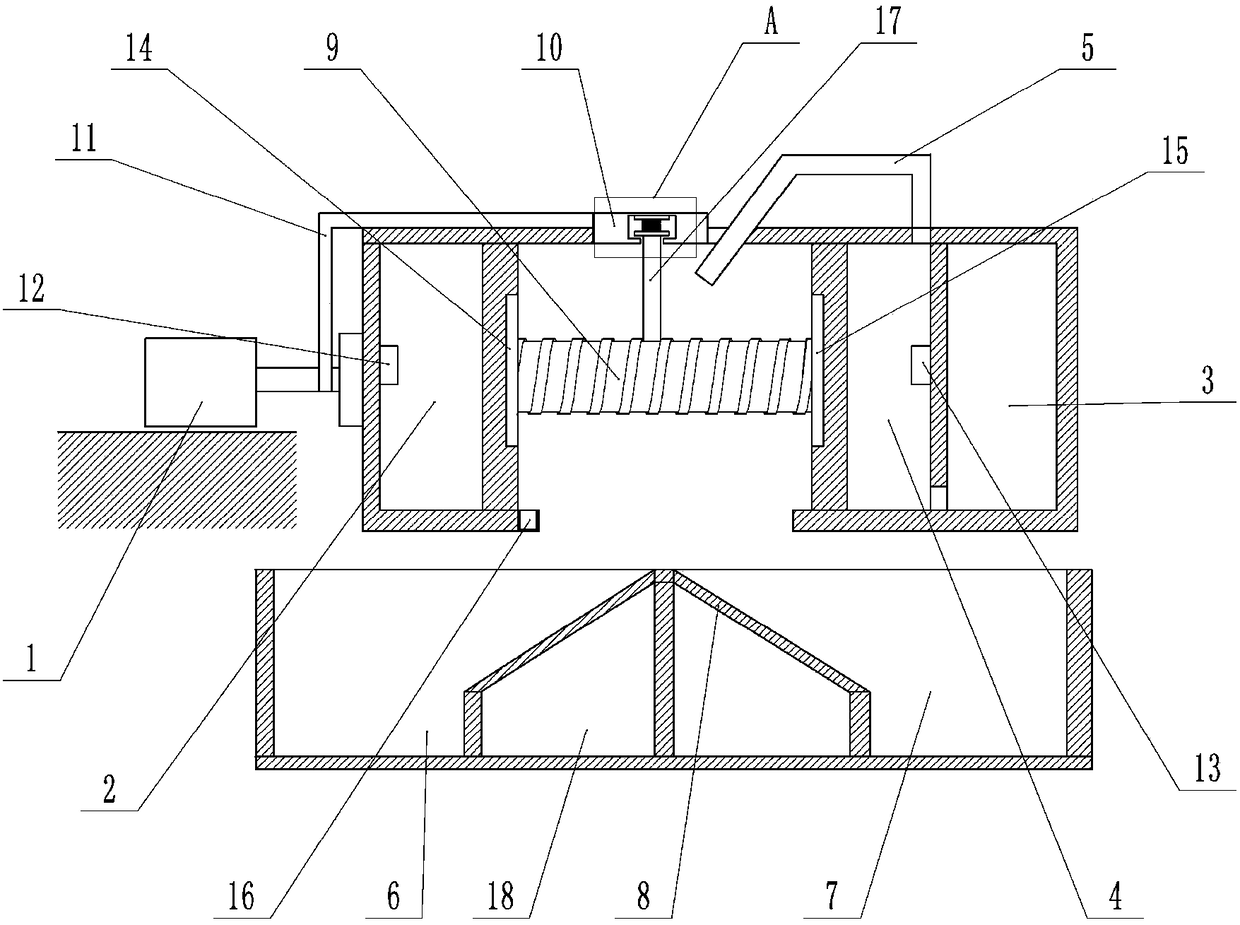

[0041] A kind of environmental protection dedusting method aimed at thread workpiece 9, comprises the following steps:

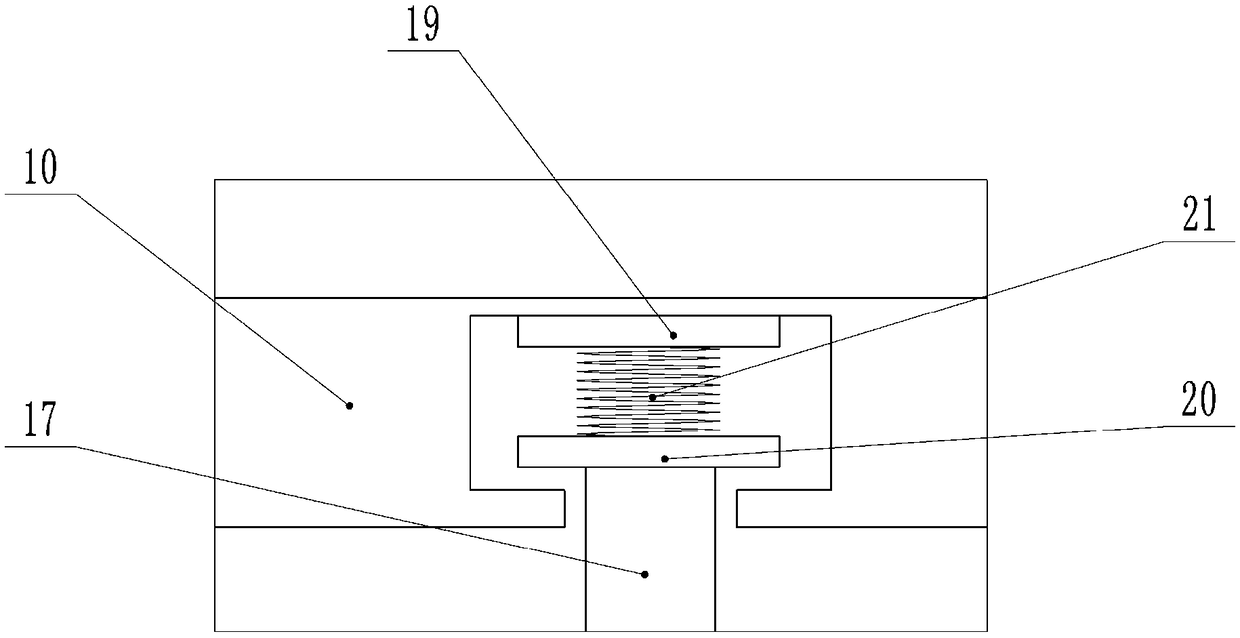

[0042] Step 1: Motor 1 is fixed on the frame, then the output shaft of motor 1 is sleeved with bearings, and cylinder 2 is fixed on the bearings; then microcontroller controls the first electromagnet 14 and hydraulic cylinder on the piston of cylinder 2 4. The second electromagnet 15 on the piston is energized, so that the two electromagnets generate mutual attractive magnetic force to clamp the two ends of the threaded workpiece 9, and then place the cleaning rod 17 on the end of the threaded workpiece 9 close to the hydraulic cylinder 4 In the threaded gap, make the gap between the cleaning rod 17 and the threaded workpiece 9 lean against;

[0043] Step 2: The microcontroller controls the motor 1 to rotate forward, the rocker 11 fixedly connected to the output shaft of the motor 1 rotates around the cylinder 2, and the slider 10 connected to the rocker 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com