Automatic control type cable uncoiling device

A driving device and cable technology, used in transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve problems such as cable damage, large cable tension, and large rolling friction between cable reels and crossbars. The effect of transportation and protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

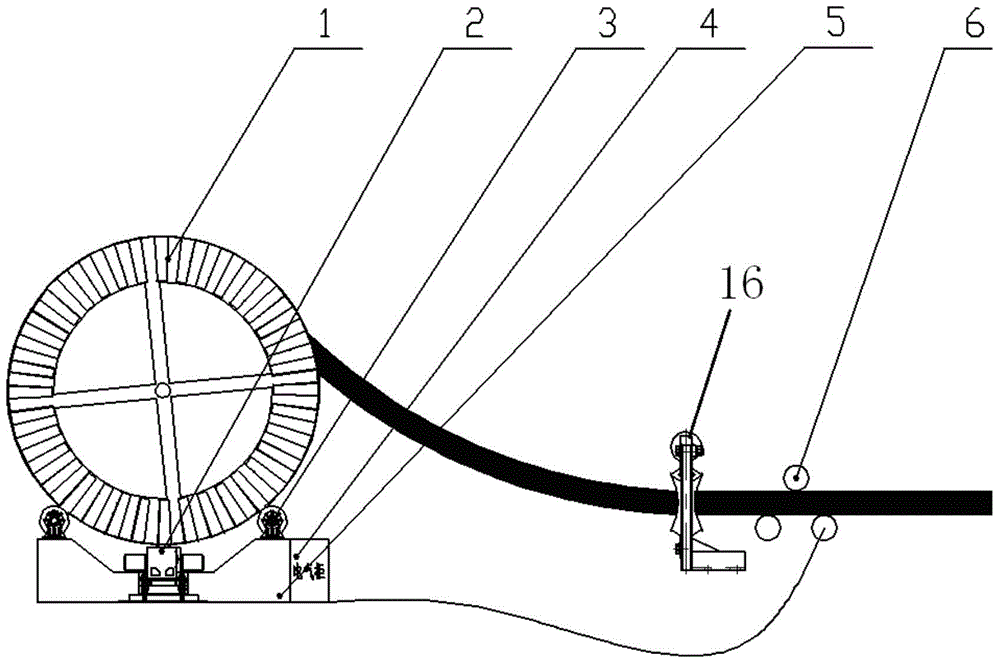

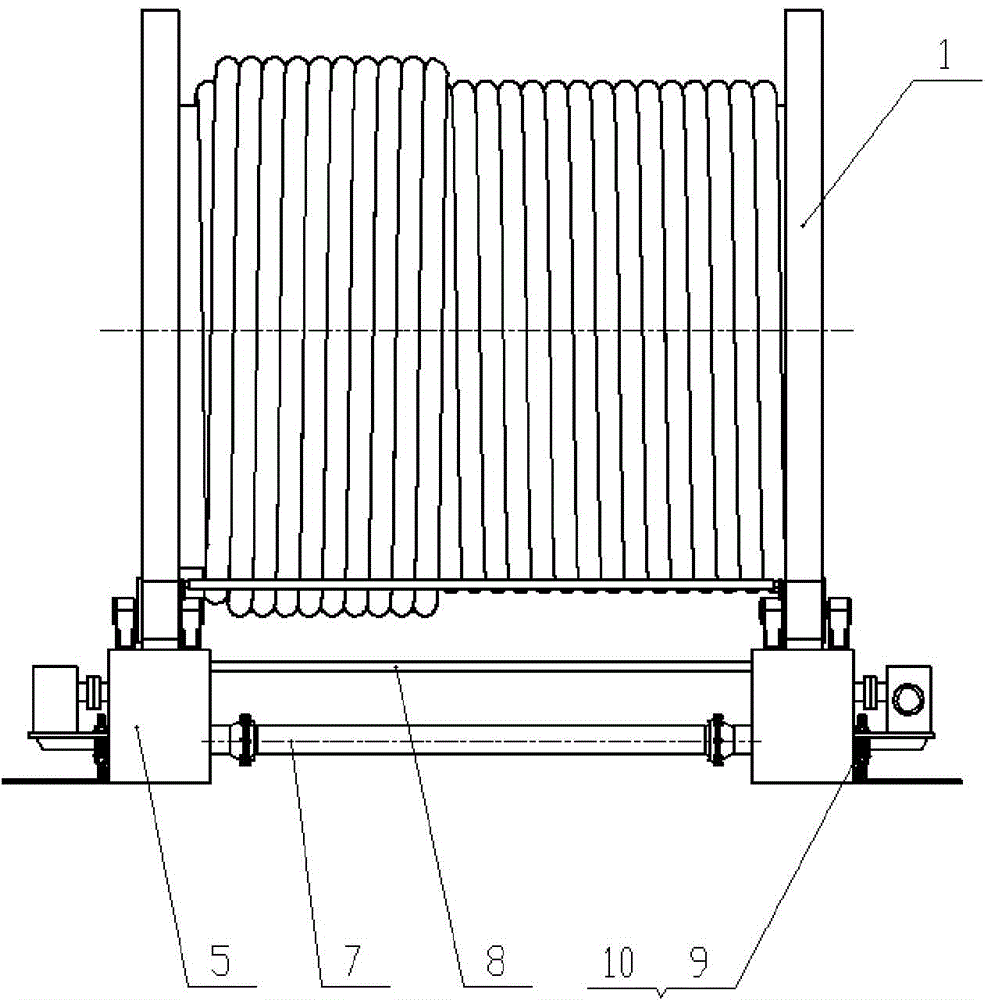

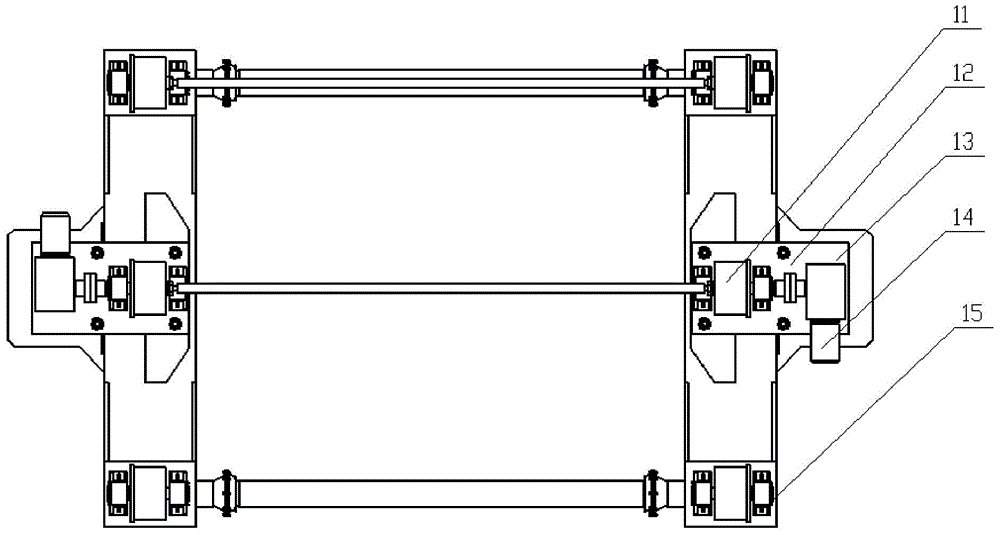

[0025] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the automatic control device for cable deployment, including two underframes 5, the two ends of each underframe 5 are provided with support wheels 3 through brackets 15, and the middle part is provided with a cable reel driving device 2, and the rim of the cable reel 1 can be connected with the support The wheel 3 and the cable reel driving device 2 are contacted and driven; a tension measuring device 6 is also included, and a control system 4 is communicatively connected with the tension measuring device 6 and the cable reel driving device 2 .

[0026] Further, the two underframes 5 are connected in a flexible way by connecting beams 7 in a ball connection. The connection mode between the connecting beam and the flexible ball of the chassis is conducive to placing the equipment on uneven ground. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com