Continuous double-face milling device for narrow-band blank

A double-sided milling and narrow-band technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems that small enterprises cannot bear, and achieve the effect of simple electrical control, easy observation, and convenient cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following are the embodiments made according to the technical solution of the present invention in conjunction with the accompanying drawings to further illustrate the present invention.

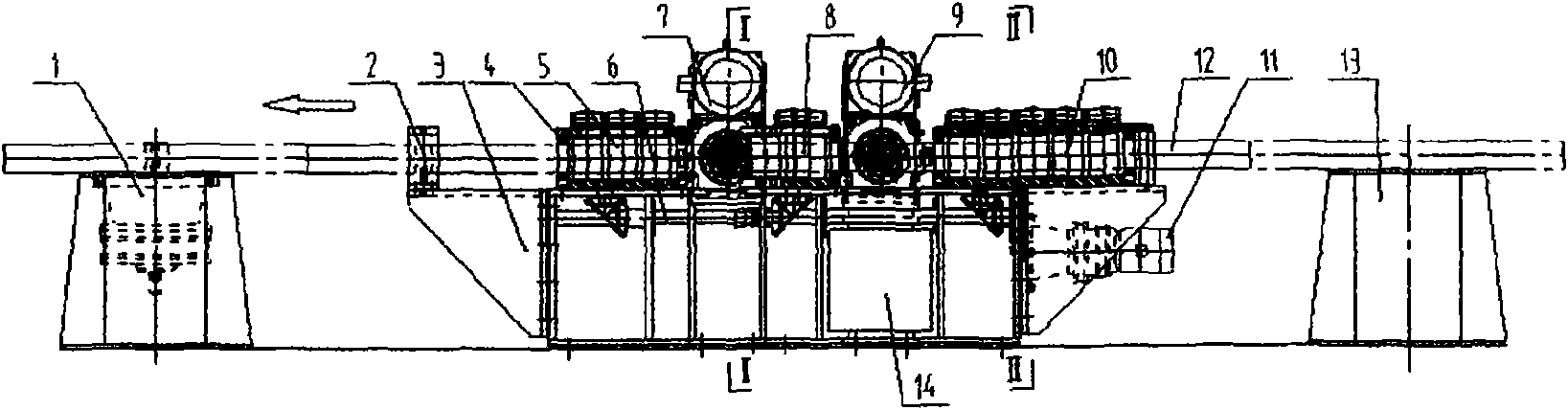

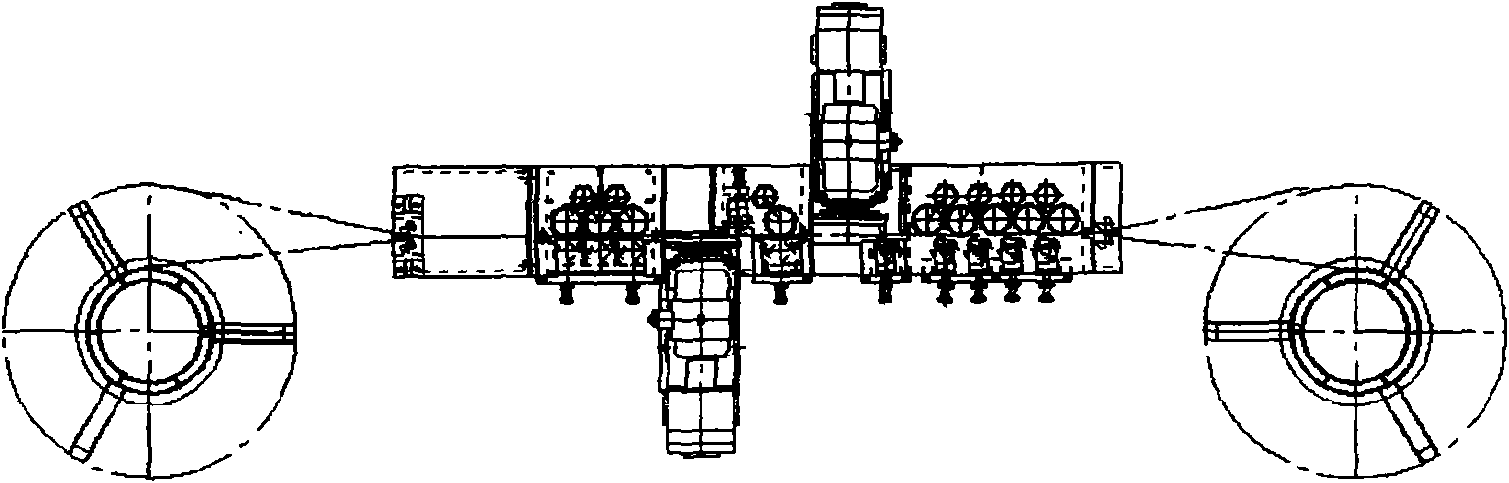

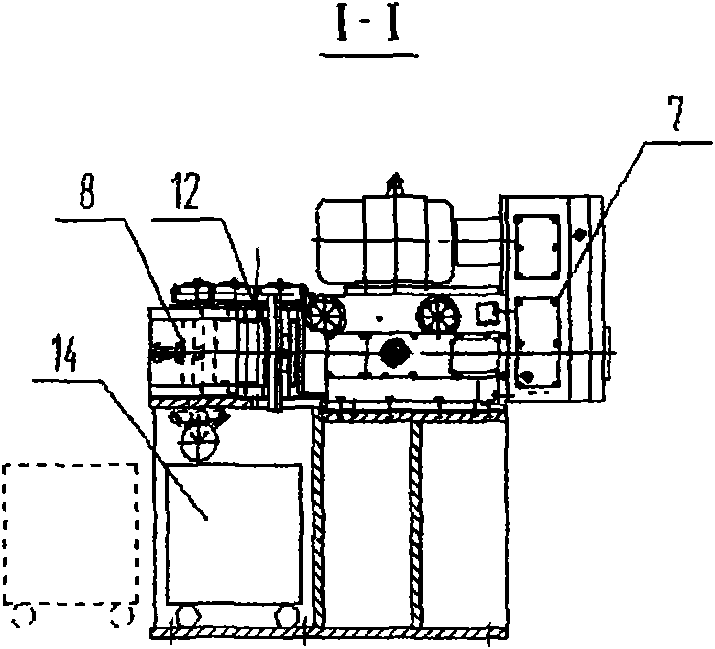

[0013] like Figure 1~4 As shown, it includes loop collection device 1, reversing roller 2, machine base 3, upper and lower horizontal pinch rollers 4, front vertical pinch roller 5, long axis transmission device 6, right combined power head 7, rear vertical clamp Sending roller 8, left combined power head 9, straightening device 10, driving device 11, strip blank 12, loop releasing device 13 and row cutting collection box 14. The front vertical pinch roller 5 , the rear vertical pinch roller 8 and the straightening device 10 are all collectively driven by the driving device 11 through the long axis transmission device 6 . The strip blank 12 is placed vertically, and after being pulled by the front and rear vertical pinch rollers 5, 8 and the straightening device 10, the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com