Adjusting device for multiple sets of strip-shaped materials

A technology of adjusting device and adjusting rod, which is applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of complicated operation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

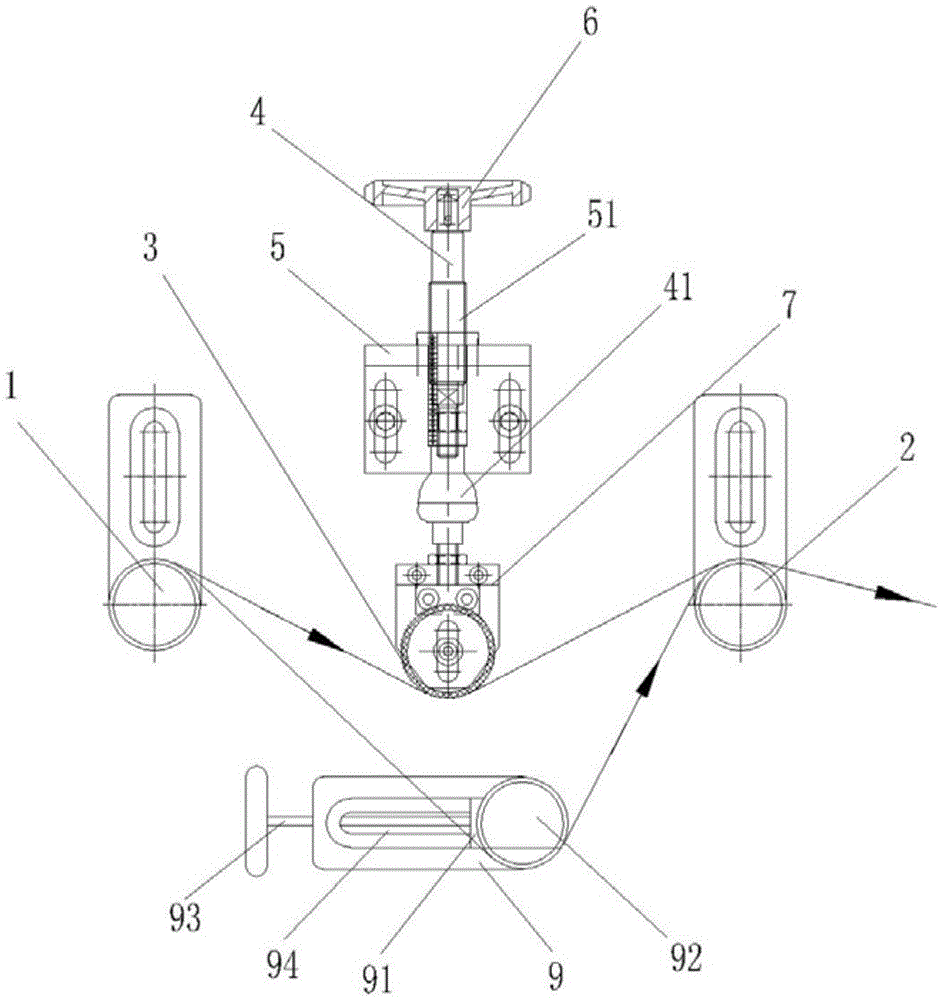

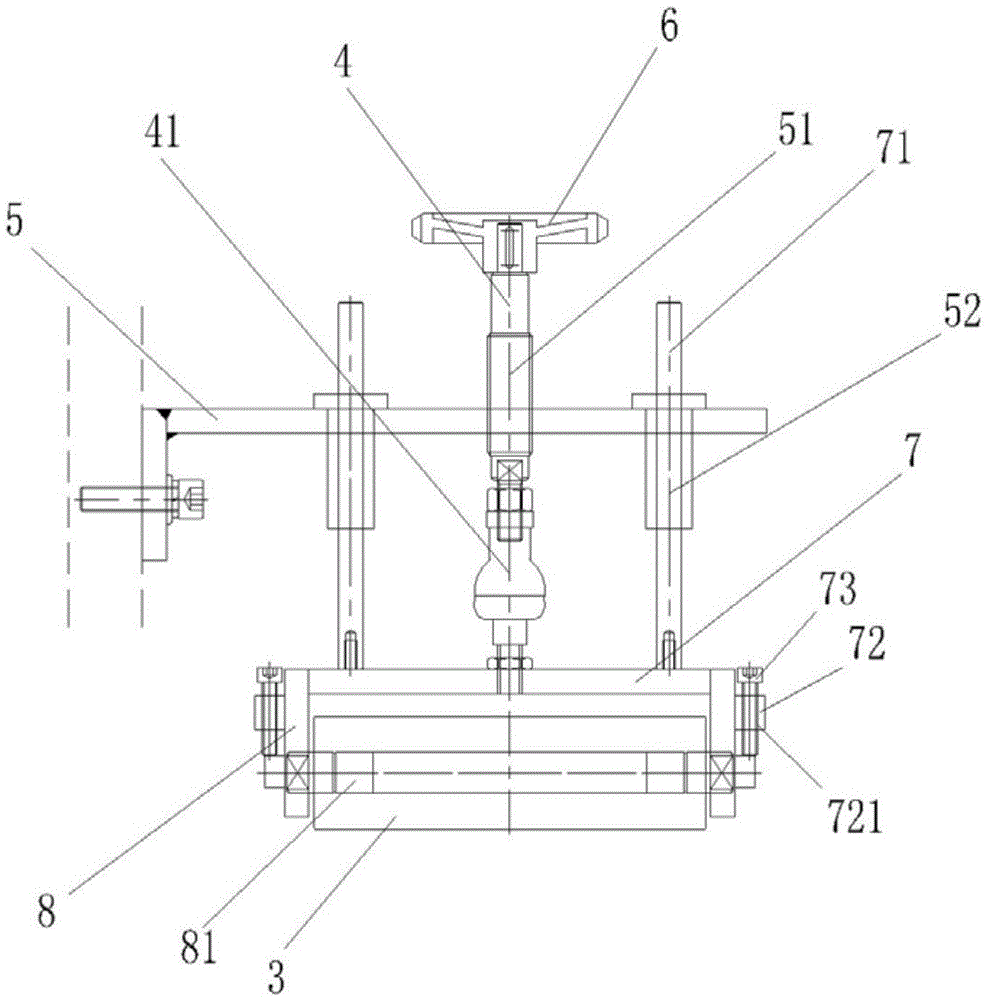

[0014] refer to figure 1 , figure 2 It can be seen that a multi-group strip-shaped material adjustment device of the present invention is characterized in that it includes a feed roller shaft 1, a material receiving roller shaft 2, a main material adjustment mechanism, an auxiliary material adjustment mechanism, a feed roller shaft 1, and a material receiving roller shaft 2. They are respectively arranged on both sides of the main material adjustment mechanism, and the auxiliary material adjustment mechanism is arranged below the main material adjustment mechanism. The fixed seat 5 is provided with a guide sleeve 51 with an internal thread, and the adjustment rod 4 is provided with an external thread, which is sleeved in the guide sleeve 51 to form a rotating and moving structure. One end of the adjustment rod 4 is fixedly connected with the adjustment handwheel 6 , the other end is connected with a joint bearing 41, and the joint bearing 41 is connected with the guide rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com