Bonding and sending device for base cloth

A technology for sending devices and base fabrics, applied in lamination devices, layered products, lamination, etc., can solve problems affecting appearance, leather wrinkles, elastic elongation of base fabrics, etc., and achieve the effect of overcoming the effect of stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

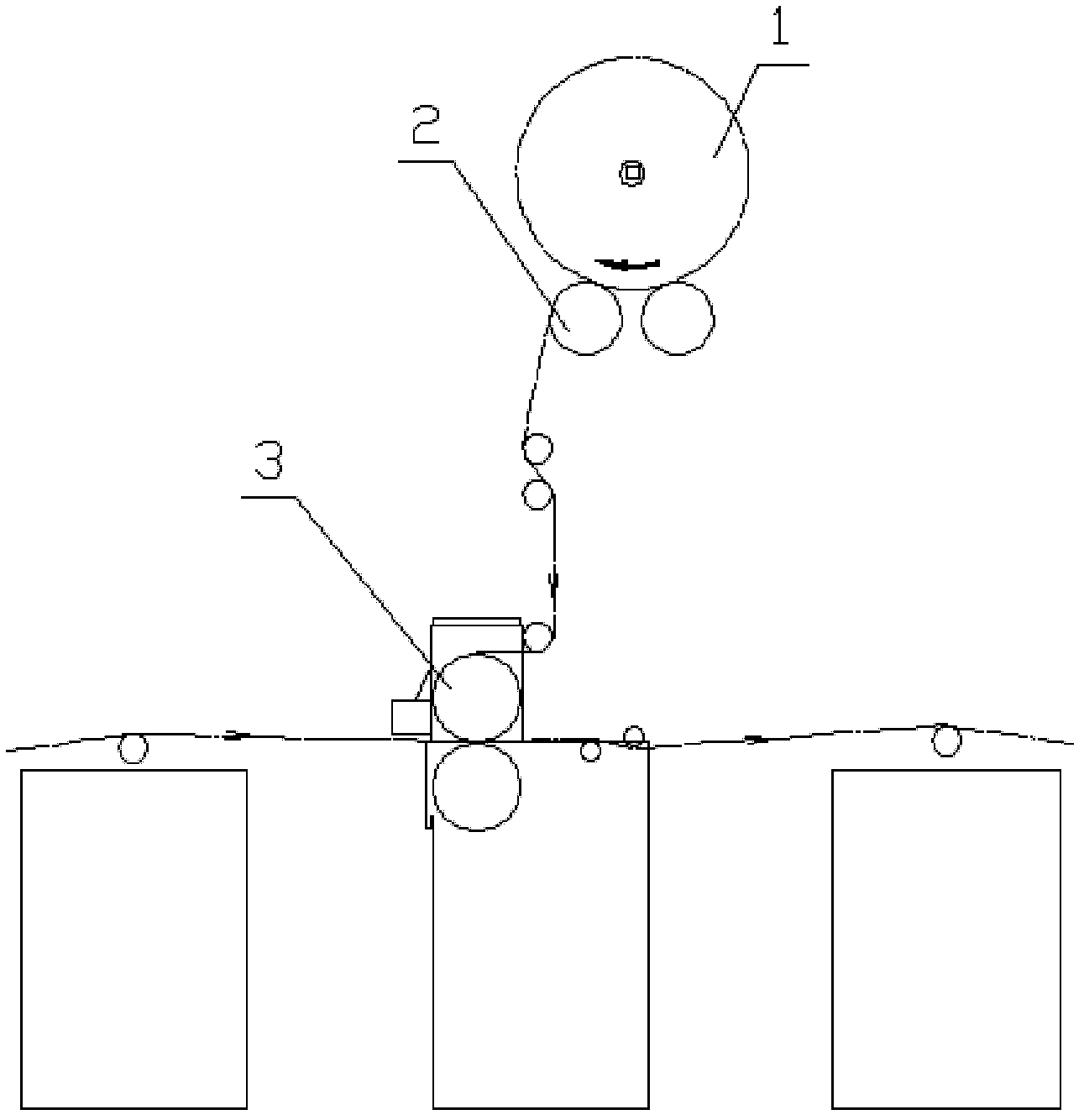

[0009] Embodiment: a base cloth laminating sending device, comprising a frame, a base cloth roller 1 and a roller driving motor, the base cloth roller 1 can be rotated and positioned on the frame, and the roller driving motor drives the base cloth roller to rotate, The frame is also provided with at least one pair of rotatable active guide wheels 2 and a guide wheel drive motor, the guide wheel drive motor can drive the paired active guide wheels 2 to rotate in opposite directions, and the paired oppositely rotated active guide wheels 2 can drive The base fabric moves. When in use, the base fabric comes out from the base fabric roller 1 and enters between the paired active guide wheels 2. The active guide wheels 2 move and output the base fabric and leather at the same speed, and pass through the bonding wheel 3 and The leather is pasted together, so that the active guide wheel 2 passes through the middle conveying process of the large roll of base cloth roller 1 and the lamina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com