A wheel-type cold milling machine factory inspection device

A cold milling machine, factory inspection technology, applied in the direction of measuring devices, machine/structural component testing, power measurement, etc., can solve the problems related to parameter matching and manufacturing assembly that cannot be found and dealt with in time, work quality and efficiency decrease, Increased machine maintenance costs and other issues, to facilitate popularization and use, reduce operational failures, improve milling quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

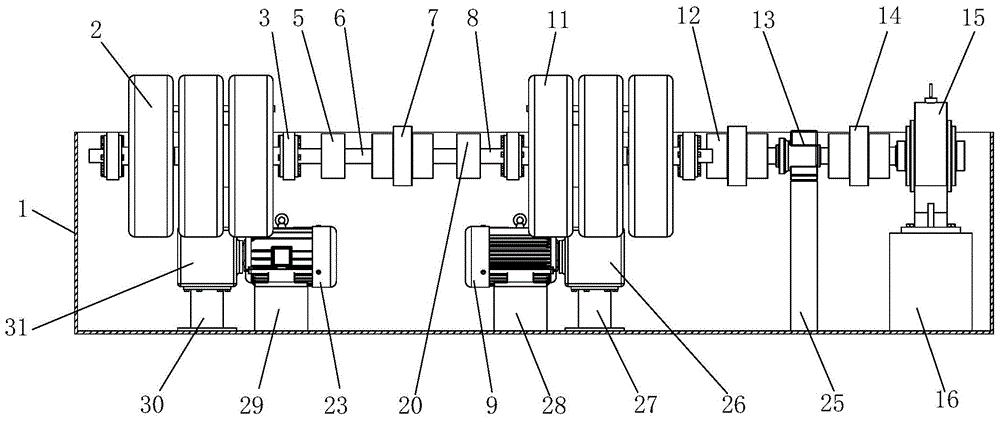

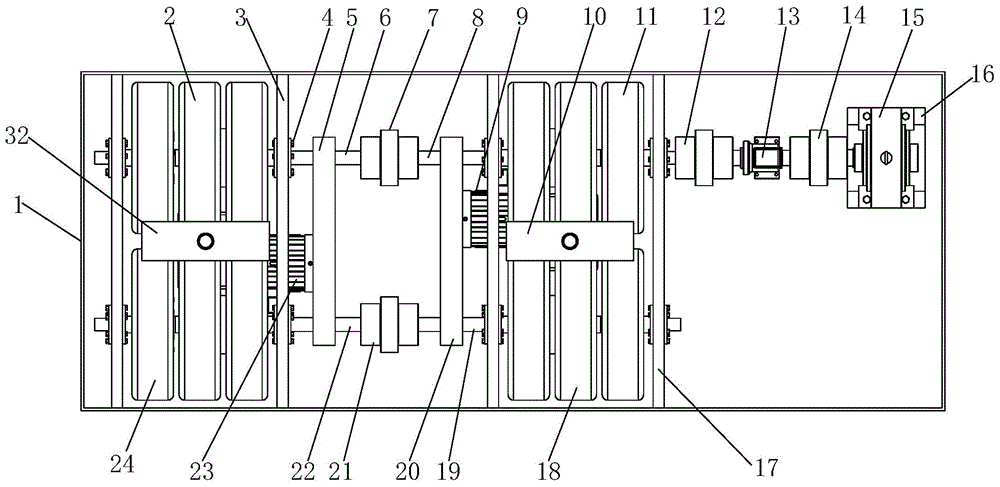

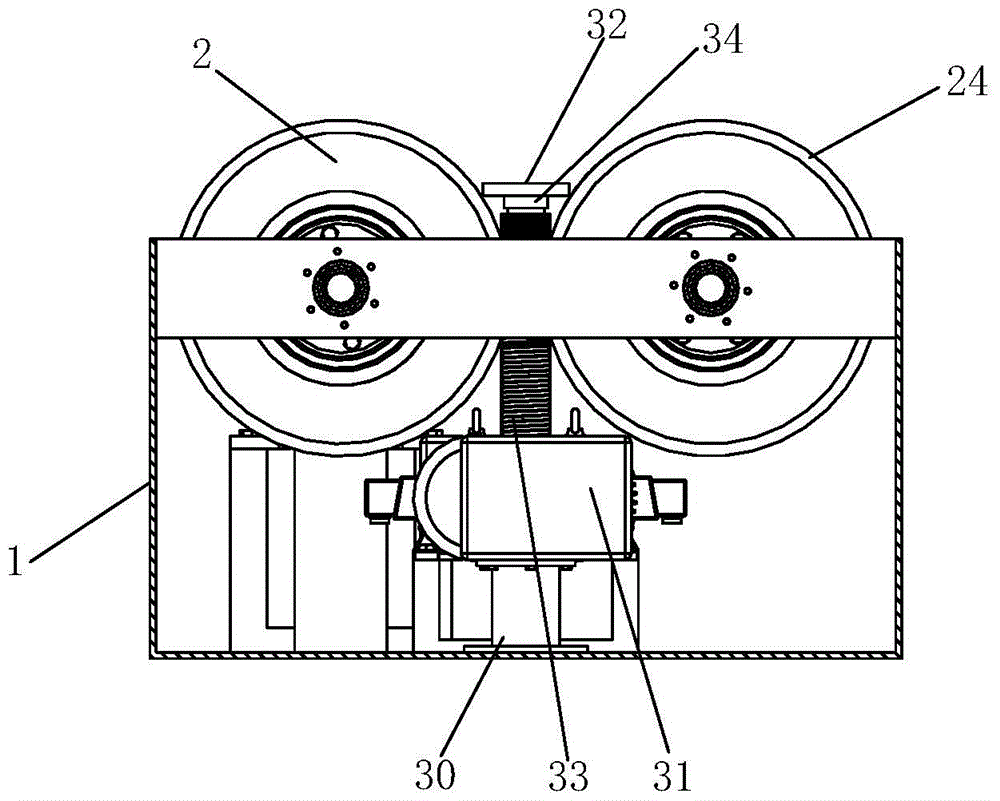

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown factory inspection device for a wheeled cold milling planer includes a walking system dynamometer, and the walking system dynamometer includes a frame 1, a torque speed sensor 13, a magnetic powder brake 15 and a dynamometer that is rotatably connected to the frame 1. The first roller 2, the second roller 24, the third roller 11 and the fourth roller 18 arranged horizontally inside, the first roller 2 and the second roller 24 are arranged correspondingly and parallel to each other, and the third roller 11 and The fourth rollers 18 are correspondingly arranged and parallel to each other. One end of the second central axis 22 on the second roller 24 is connected with one end of the fourth central axis 19 on the fourth roller 18. The first central axis on the first roller 2 One end of the shaft 6 is connected to one end of the third central shaft 8 on the third drum 11, and the other end of the third centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com