Segment assembling derrick and construction method thereof

A segment assembly and derrick technology, which is applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of large construction area and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

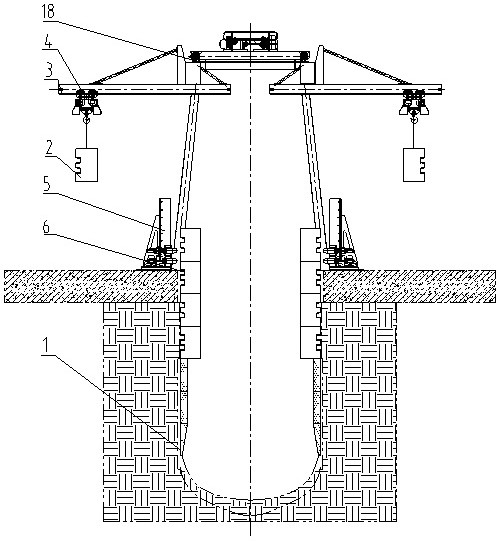

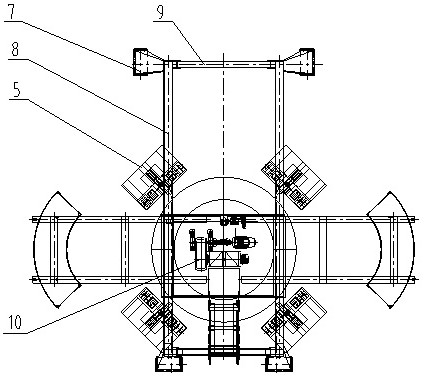

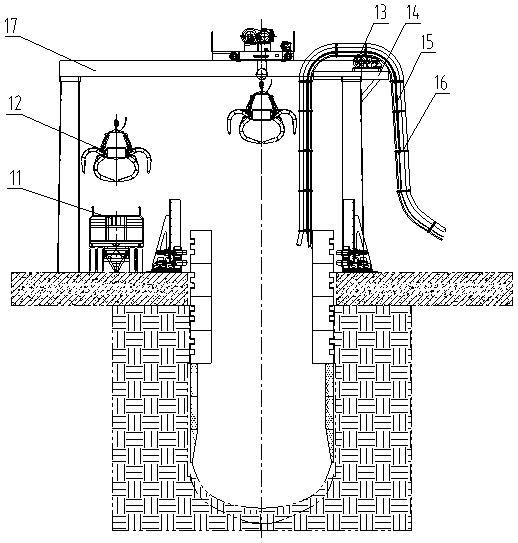

[0030] Embodiment 1: as figure 1 As shown, a segment-assembled derrick includes a frame 17, on which a trolley 10 is slidably arranged, and a cable lowering mechanism is arranged at the end of the frame 17, and the cable lowering mechanism is used for the excavation process of the roadheader. When the middle pipeline is lowered, the trolley 10 is connected with the slag discharge mechanism, and the slag discharge mechanism is driven by the trolley to transfer the slag in the shaft. Cantilever mechanisms 3 are arranged symmetrically on both sides of the frame 17, and the cantilever mechanisms are arranged symmetrically about the center of the shaft. The cantilever mechanism 3 is provided with a crane 4, and several groups of segment lowering devices 5 are arranged symmetrically under the frame 17. The segment lowering device 5 cooperates with the crane 4, and the segment lowering device is used to lift the crane into place and assemble The completed pipe joints are lowered, and...

Embodiment 2

[0038] Embodiment 2: as figure 1 Shown, a kind of working method of segment assembly derrick comprises the following steps:

[0039] S1. Segment installation preparation: first, open the outer shaft wellhead for pretreatment, install the starting pipe joint 1 and the roadheader in the starting shaft in sequence, and then install the segment lowering device 5 and the erection frame 17 symmetrically around the wellhead, and install them on the machine. Cantilever mechanism 3 is installed symmetrically on both sides of frame 17, crane track and crane 4 are set up on the cantilever mechanism 3, walking trolley 10 is erected on frame 17, and the cable lowering mechanism is fixed at the end of frame 17;

[0040] S2. Segment assembly: the segment is lifted by the crane 4 and travels along the specific crane track to a predetermined position for segment assembly. The personnel assemble and connect the segment 2 on the ground, and connect and fix the adjacent segments. After the segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com