Tension self control structure for continuous crabbing machine

A kind of technology for fabricating machine and tension, which is applied in textile processing machine accessories, textiles and papermaking, and winding strips, etc. It can solve the problems of large range of fabric tension changes, low accuracy, and insufficient stability of fabric conveying, etc., to achieve control Accurate process and smooth fabric delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

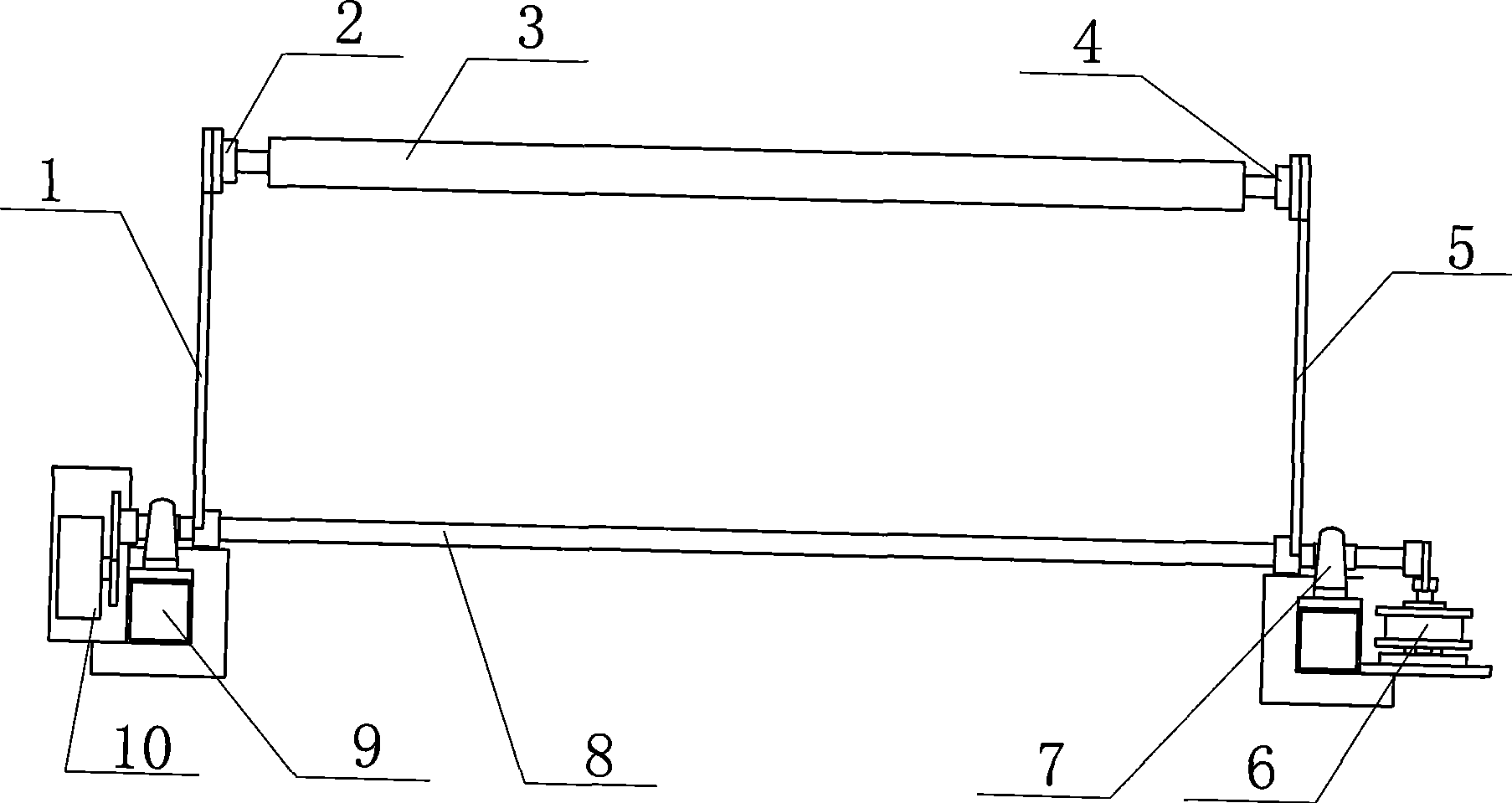

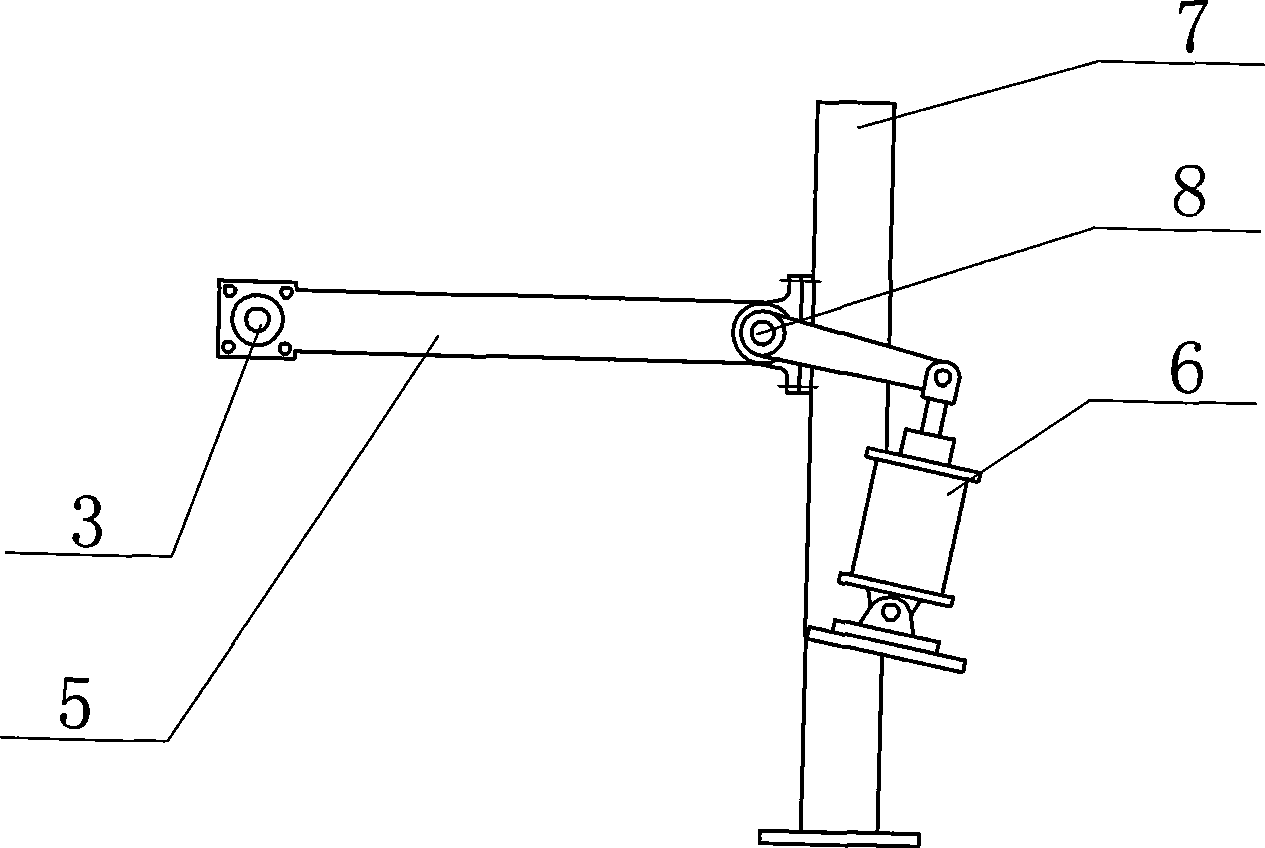

[0008] See figure 2 , the present invention comprises transmission shaft 8, and transmission shaft 8 is installed in bearing housing 7,9, and one end of transmission shaft 8 is connected with the piston rod of cylinder 6, and the other end of transmission shaft 8 is equipped with sensor 10, and sensor 10 and control cylinder 6 The electromagnetic valve is electrically controlled, and the two ends of the transmission shaft 8 are respectively sleeved and connected to the connecting rods 1 and 5, which are rotatably connected. The connecting rods 1 and 5 are connected to the guide roller 3 through the bearing seats 2 and 4 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com