Material head cutting mechanism for synthetic plastic part production

A technology for plastic parts and material heads, which is applied in the field of material head cutting mechanisms for the production of synthetic plastic parts, can solve the problems of difficulty in being accurate, slow in efficiency, and difficult to maintain operations, and achieves the effect of increasing cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

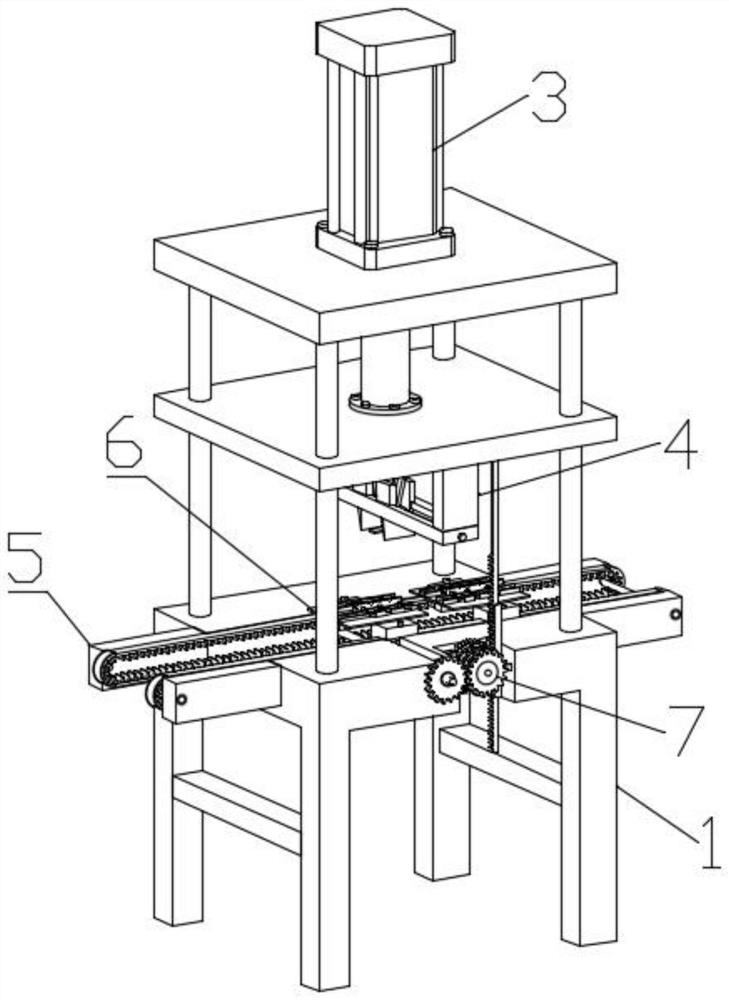

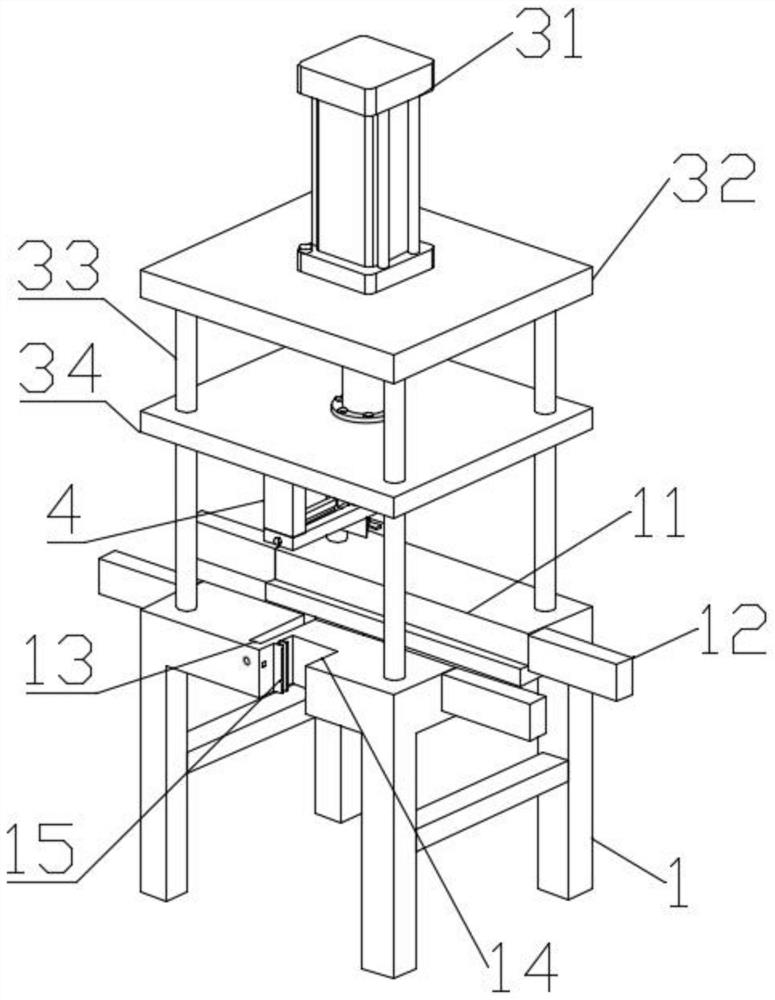

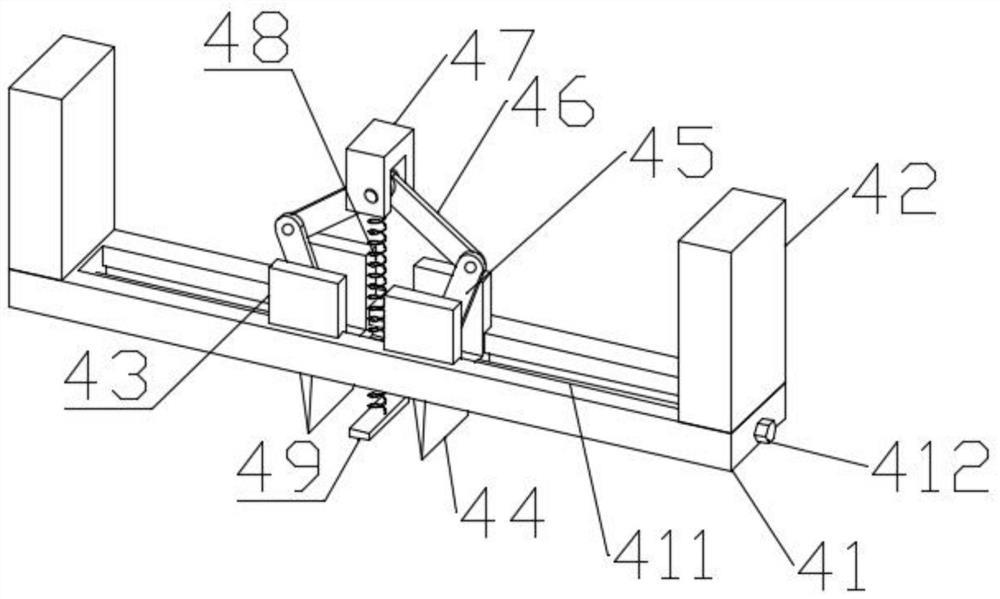

[0023] Example: such as Figure 1 to Figure 7 As shown, the present invention provides a synthetic plastic parts production head cutting mechanism, including a bottom frame 1, a rectangular through groove 11 is opened on the upper surface of the bottom frame 1, and rectangular blocks 12 are fixed on both sides of the bottom frame 1 , the transmission mechanism 5 is installed in rotation between the rectangular blocks 12, the transmission mechanism 5 can be fixedly installed on the bottom frame 1, and can be stably transmitted, and the upper surface of the bottom frame 1 is provided with a turning groove 13 and a mounting groove 14, A synchronous mechanism 7 is installed in rotation in the installation groove 14, and the synchronous mechanism 7 is fixedly installed. The inner wall of the installation groove 14 is fixedly installed with a limit block 15, and the upper surface of the bottom frame 1 is fixedly installed with a pushing device 3. The upper end of the mechanism 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com