Helical air duct forming machine with main machine capable of synchronously cutting without halt

A spiral air duct and synchronous cutting technology, which is applied to devices for shearing and forming blanks, shearing devices, shearing machines, etc., can solve the problems of uneven trimming, low efficiency and no main machine, and achieve synchronous cutting without stopping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

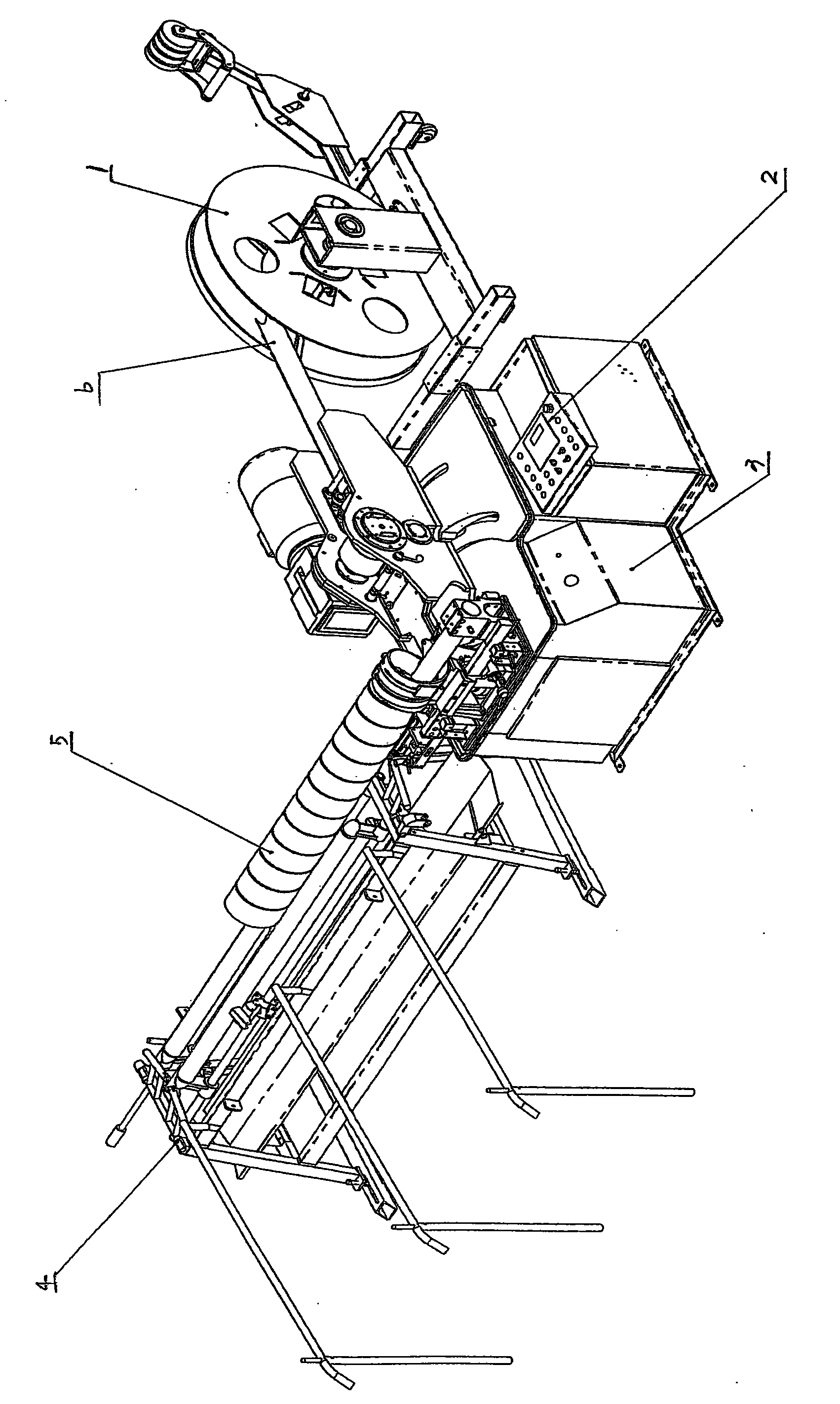

[0023] see figure 1 , the main engine of the present invention can realize the non-stop synchronous cutting of the spiral air duct forming machine, which is mainly composed of three parts: an uncoiler 1, a main engine 3 and an unloading table 4. The uncoiler 1 is placed on the rear side of the main machine 3, and the unloading platform 4 is placed on the side of the main machine 3.

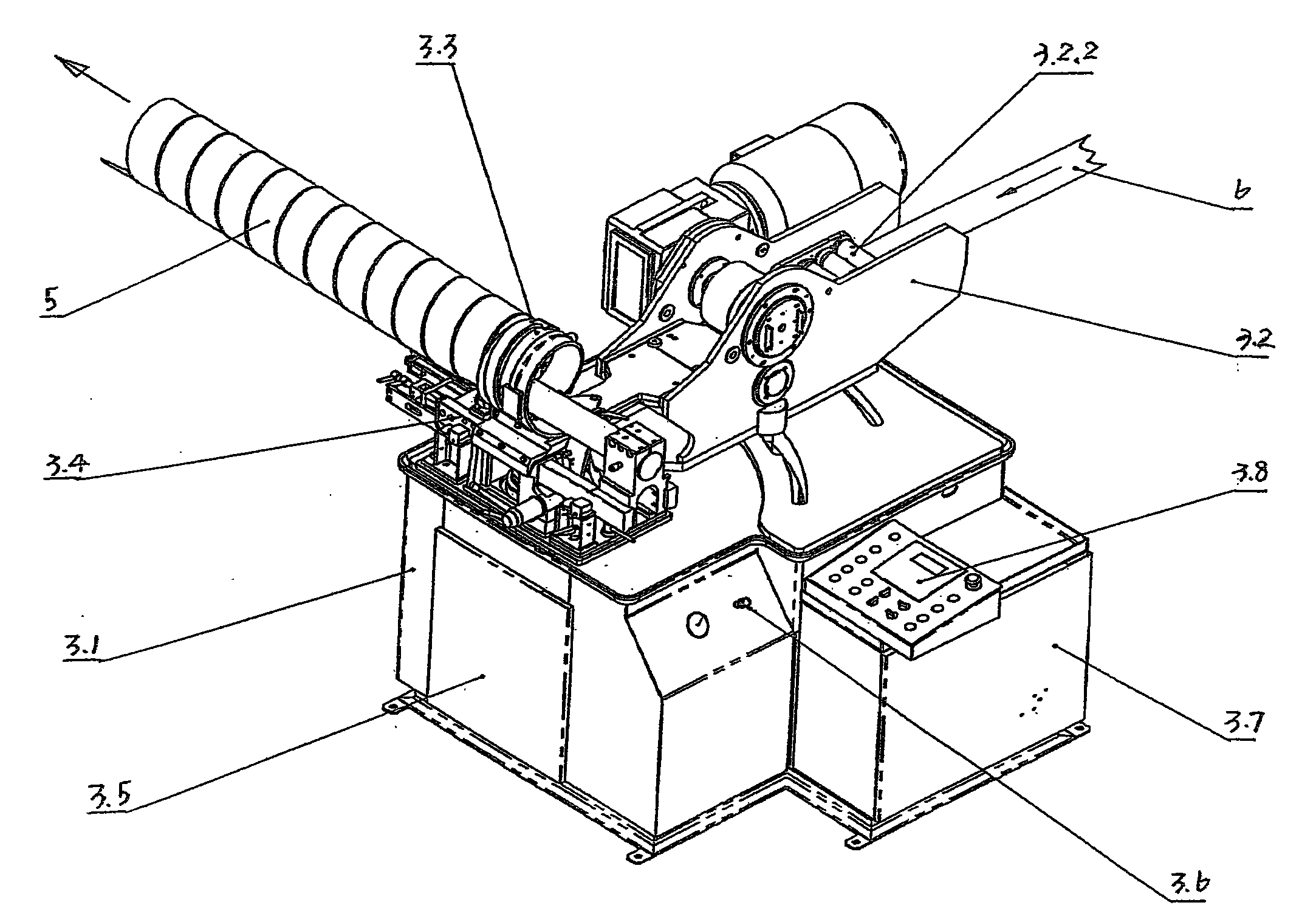

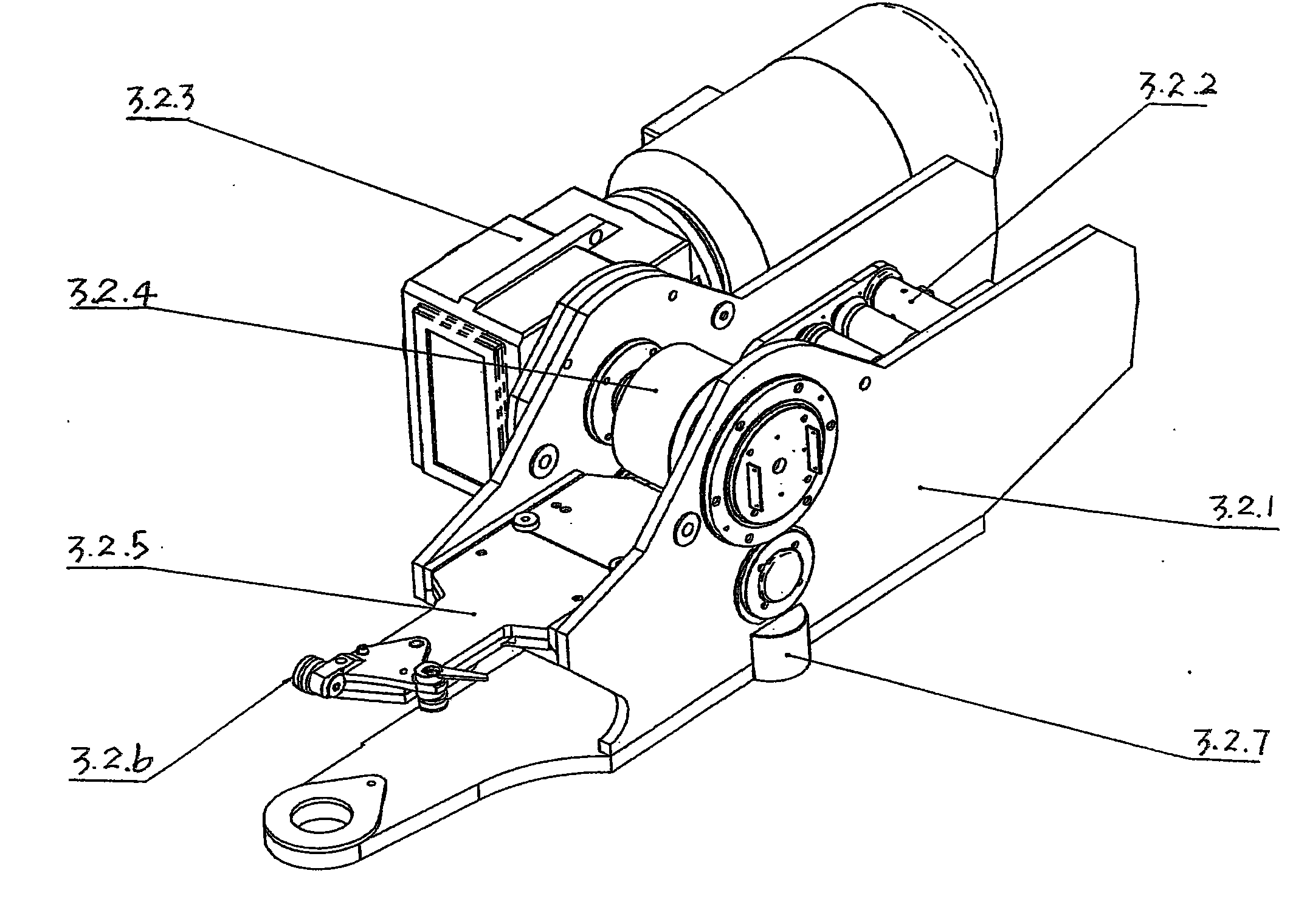

[0024] see figure 2 , the main frame 3 is mainly composed of a main frame 3.1, a nose box assembly 3.2, a mold 3.3, a flying shear assembly 3.4, a hydraulic station 3.5, a pressure regulating valve 3.6, an electric cabinet 3.7 and an electrical operation box 3.8. Described nose box assembly 3.2, mold 3.3 and flying shear machine assembly 3.4 are all installed on the main machine frame 3.1, and mold 3.3 is placed on the front side of nose box assembly 3.2, and flying shear machine 3.4 assembly is placed on mold 3.3 Below, the hydraulic station 3.5 and the electric cabinet 3.7 are installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com