Cutting device integrating cutting and pressing

A cutting device and integrated technology, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of high equipment cost, poor quality of manual cutting, low production efficiency, etc., and achieve high degree of automation and cutting The effect of good quality and low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

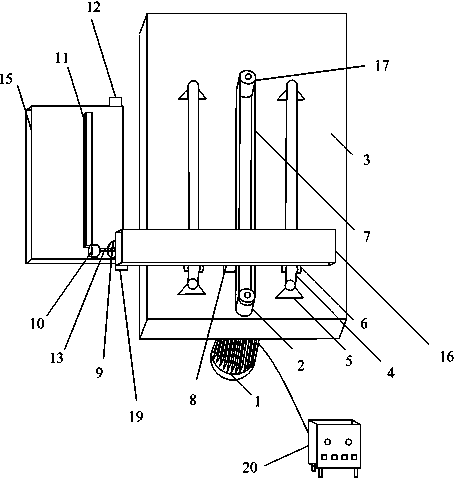

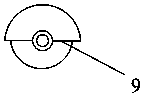

[0018] A cutting device integrating cutting and pressing, comprising a machine platform 3, a feeding bed 15, and a PLC controller 20, the machine platform 3 is provided with a guide rail 4, and the guide bar 16 is installed on the guide rail 4 through the guide rail groove 6 , the machine table 3 is also provided with a first rotating shaft 2 and a second rotating shaft 17, the motor 1 drives the first rotating shaft 2 to rotate, one side of the guide bar 16 is provided with a cutting knife 9, and the cutting knife 9 passes through the second The three rotating shafts 13 are connected with the pressure roller 10, and grooves 14 are arranged on both sides of the material selection bed 15.

[0019] The guide rail 4 is fixed on the machine platform 3 through a support 5 .

[0020] A friction block 8 is arranged below the guide bar 16 .

[0021] The transmission between the first rotating shaft 2 and the second rotating shaft 17 is through a chain 7 .

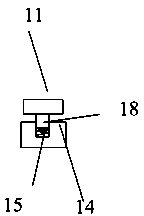

[0022] The bead 11 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com