Casting three-dimensional process designing method

A process design, three-dimensional technology, applied in the field of casting three-dimensional process design, can solve the problems of lack of knowledge accumulation, low yield, low pass rate, non-unique data source, etc., to achieve shortened cycle, improved yield, and guaranteed quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

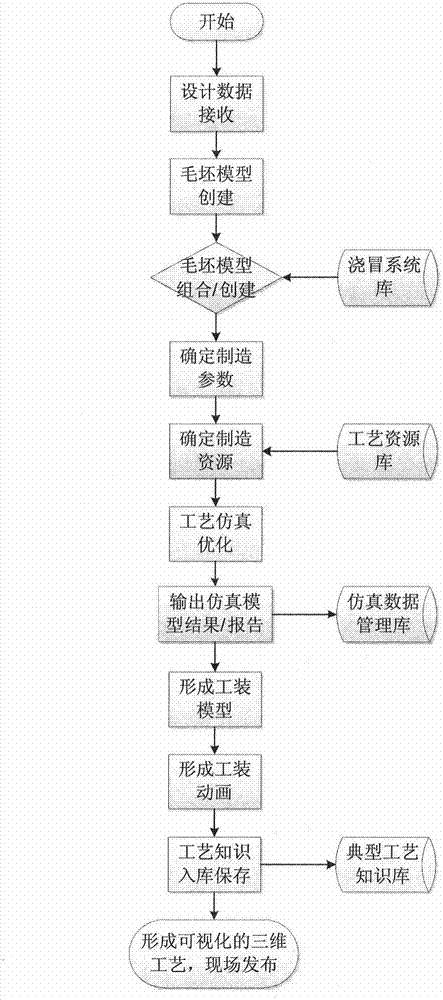

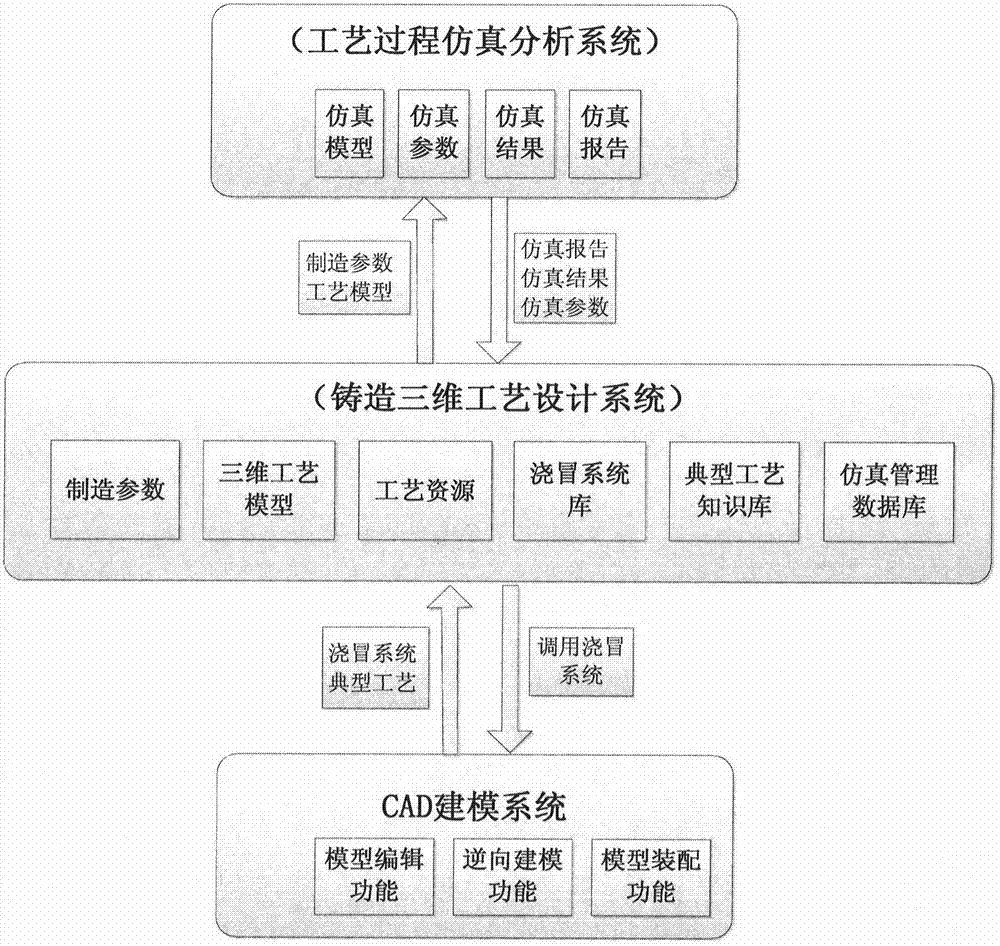

[0018] Such as figure 1 , 2 As shown, the casting three-dimensional process design method of the present invention comprises the following steps:

[0019] 1) Receive product data from the design database, including product 3D model, manufacturing information, technical requirements, etc.;

[0020] 2) Open the product design model in the integrated casting 3D process design system, and generate the casting blank model based on the design model combined with manufacturing information;

[0021] 3) Select a suitable rigging system in the system and assemble the blank model to form a casting process model. If no suitable rigging system is found, it will be recreated to form a new knowledge accumulation;

[0022] 4) Determine the manufacturing parameters and form a manufacturing card;

[0023] 5) Determine the process resources that need to be applied in manufacturing, and form a manufacturing card;

[0024] 6) Enter the process simulation interface, and the manufacturing parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com