Electromigration reliability test structure and making method for multilayer of metal interconnected metal wires

A test structure, multi-layer metal technology, applied in circuits, electrical components, measurement devices, etc., can solve the problems of long life test time and a large number of sample packaging, so as to reduce test costs, test samples, and test time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

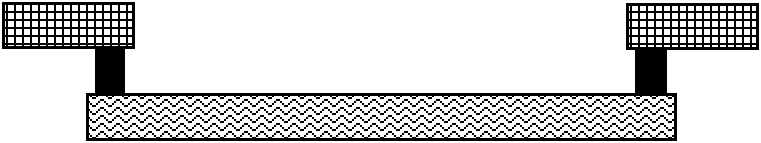

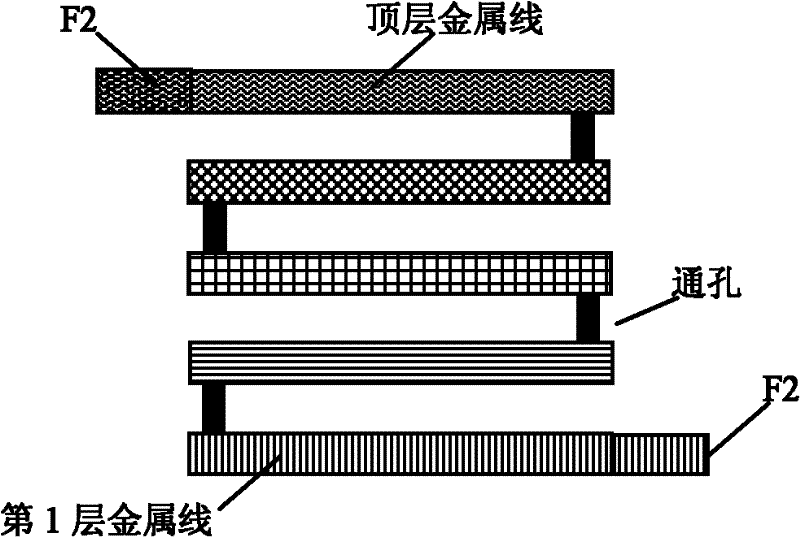

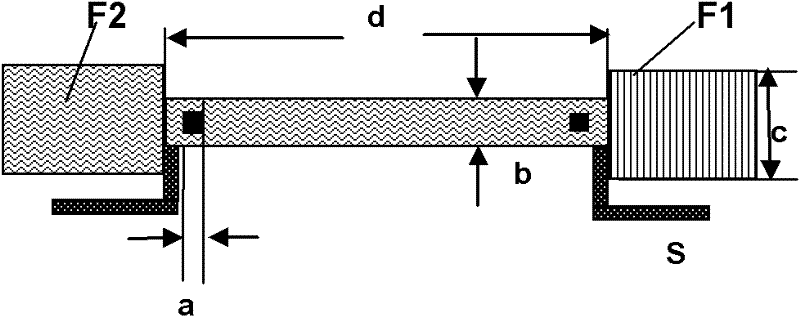

[0015] The electromigration reliability test structure of the multilayer metal interconnection metal wire of the present invention comprises a multilayer metal wire, the length of the metal wire is greater than or equal to 200 microns, and other parameters of the metal wire are the same as the chip design to be tested, and every two layers The metal wires are connected by through holes to form a "bow"-like structure; the end of the first layer of metal wires far away from the through holes and the end of the top layer of metal wires far away from the through holes are respectively provided with current input ends; each metal wire The two ends are respectively provided with voltage measuring terminals. The metal wires in each layer are the same length.

[0016] figure 2 Be a specific embodiment of the present invention, wherein metal wire is 5 layers, the length d of metal wire is chosen 400 microns, width b, the size a of through hole all is the design requirement setting of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com