Hybrid flow shop scheduling method

A technology of workshop scheduling and flow, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problem of not considering parallel batch processing, preparation time and assembly at the same time, parallel batch processing, preparation time and less research on assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] The preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

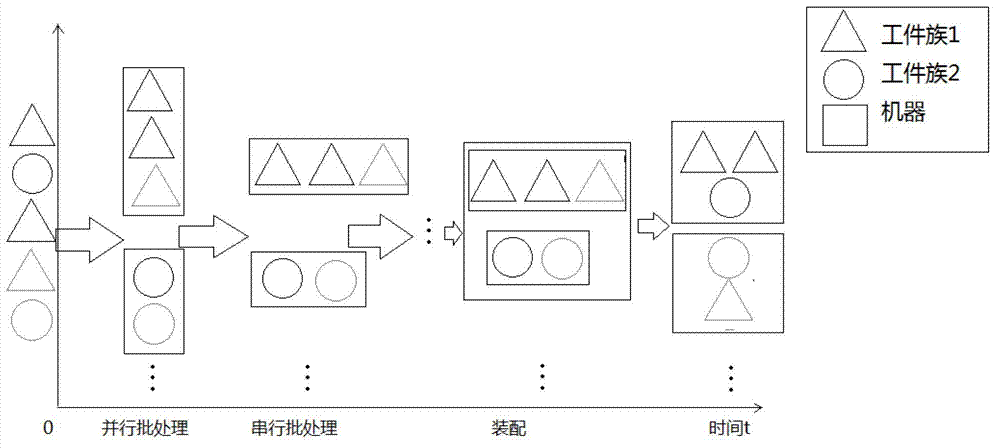

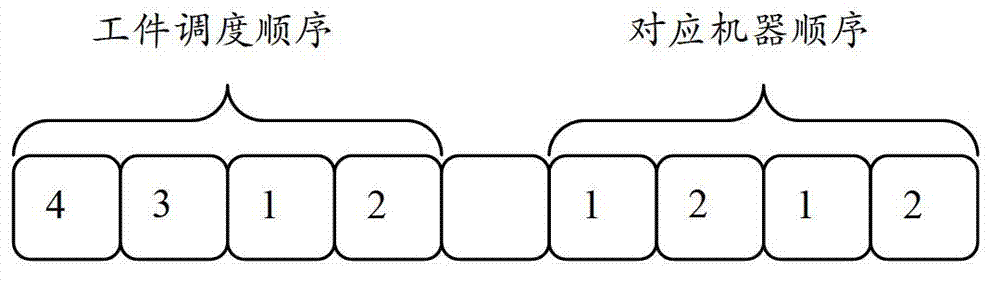

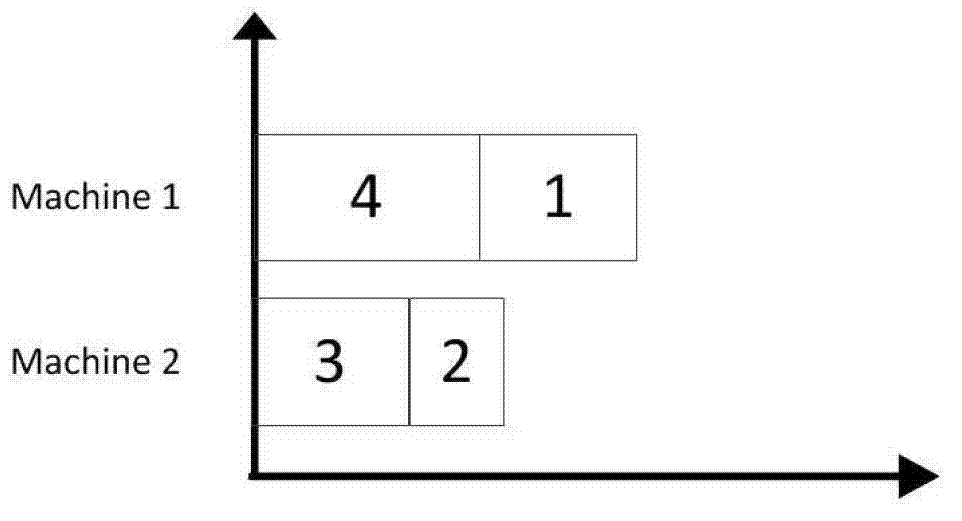

[0113] This embodiment implements the hybrid scheduling algorithm of parallel batch processing, serial batch processing and assembly based on the heat treatment furnace margin minimum difference method and genetic algorithm proposed by the present invention according to the execution steps in the summary of the invention, such as Figure 8 shown.

[0114] The solution of the present invention is divided into two stages: batching and batch scheduling. The first stage of batching is a very critical step, because batching not only directly affects the utilization rate of heat treatment furnaces, but also indirectly affects the scheduling results. If the batching effect is not good, no matter how good the scheduling algorithm is, the scheduling solution may not be effective. Therefore, in order to verify the effectiveness of the batch heu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com