Aluminum-plastic blister packaging machine

A blister packaging machine, aluminum-plastic technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems that affect the production progress, no collection and arrangement at the feeding port, and inconvenient cleaning of equipment, so as to reduce time and work Quantity, reduce equipment debugging time, improve the effect of product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

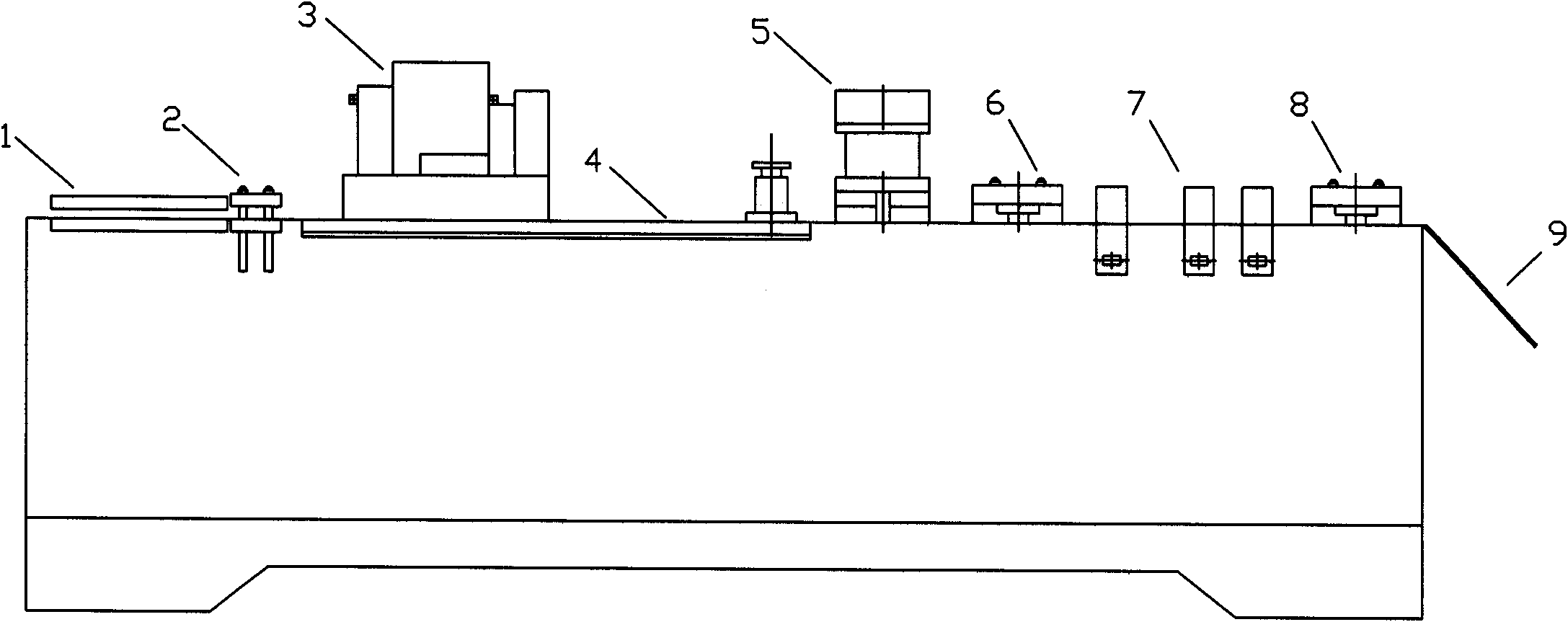

[0023] The present invention will be introduced in detail below with reference to the accompanying drawings: the present invention is an improvement on several parts of the DPP-250C aluminum-plastic packaging machine, which facilitates production debugging to the greatest extent and solves the problem of large dust. Various parts have been improved, as follows:

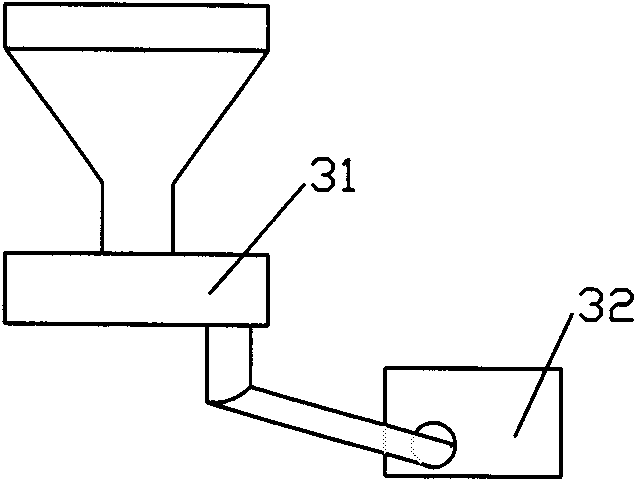

[0024] 1. The packing parts of the existing DPP-250C aluminum-plastic packaging machine on the market need to be manually operated due to the structure of the feeder, which brings inconvenience to production. Through transformation, the original packing part is changed to a packing device with a vibrating screen and a closed track, and the feeding is made from the side opening, so that the material will not be split or fragmented due to the high drop height.

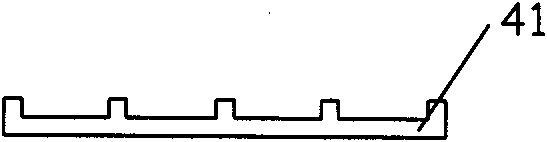

[0025] 2. Most of the existing DPP-250C aluminum-plastic packaging machines on the market need to repeatedly adjust the indentation position of the batch number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com