Control method and system against batch mix-up in PCB production process

A control method and production process technology, applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, printed circuit components, etc., can solve product quality problems that cannot be traced back, analyze and improve quality problems, mixed batches, etc. Eliminate the phenomenon of mixed batches, avoid quality accidents, and facilitate reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

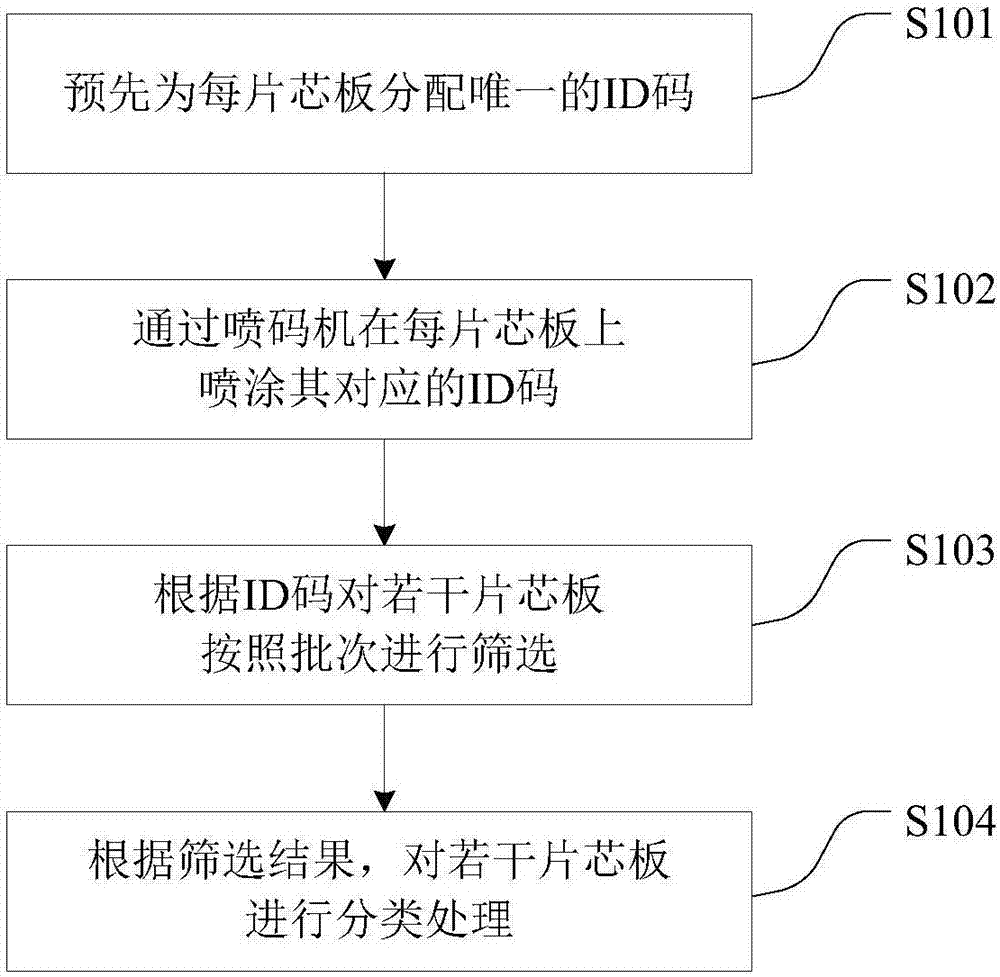

[0039] see figure 1 , the present embodiment provides a method for controlling anti-mixing batches in the PCB production process, comprising the following steps:

[0040] Step S101, assigning a unique ID code to each chip board in advance.

[0041] The ID code is also called 8421 code, which is allocated according to the principle of uniqueness. In order to achieve accurate traceability of quality, its information includes: model, batch number and core board number.

[0042] Step S102, spraying its corresponding ID code on each core board with an inkjet printer.

[0043] For the convenience of reading, the spraying position is preferably set to a fixed area of the board edge of the core board.

[0044] Step S103 , according to the ID code, the several chip boards are screened according to the model and batch number.

[0045] The screening process includes:

[0046] Set the model and batch number for this screening;

[0047] Put each core board to be screened in turn;

...

Embodiment 2

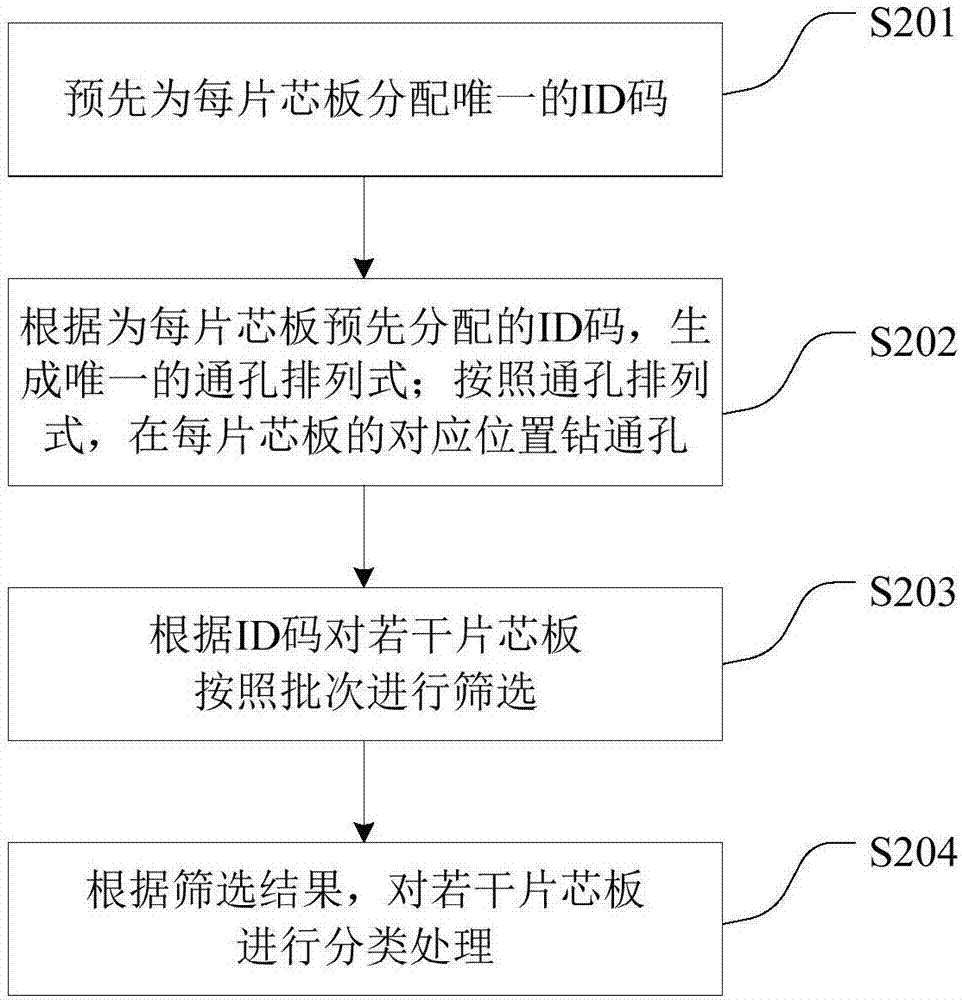

[0054] In Embodiment 1, the ID code is set by spraying. However, in the subsequent production process, the information formed by spraying is easily covered or affected, making it unclear and unable to be read accurately and quickly. Therefore, the second embodiment optimizes the solution of the first embodiment.

[0055] see figure 2 , the present embodiment provides a method for controlling anti-mixing batches in the PCB production process, comprising the following steps:

[0056] Step S201, assigning a unique ID code to each chip board in advance.

[0057] The ID code is also called 8421 code, which is allocated according to the principle of uniqueness. In order to achieve accurate traceability of quality, its information includes: model, batch number and core board number.

[0058] Step S202 , according to the pre-assigned ID code for each core board, generate a unique through hole arrangement; according to the through hole arrangement, drill through holes at the corres...

Embodiment 3

[0071] This embodiment provides a control system for anti-mixing batches in the PCB production process, including: an ID code setting device and a core board screening device.

[0072] The ID code setting device is used to pre-allocate a unique ID code for each core board, and set its corresponding ID code on each core board. The information content of the ID code includes: model, batch number and core board serial number;

[0073] The core board screening device is used to screen several core boards according to batches according to the ID code.

[0074] Wherein, the ID code setting device further includes: a hole row generation unit, used to generate a unique through hole arrangement according to the ID code pre-assigned for the current core board; Permutation, drill through holes at the corresponding position of the current core board.

[0075] Wherein, the core board screening device further includes: a setting unit for setting the model and batch number of each screenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com