Multifunctional environment-friendly asphalt flue gas purification system

A technology of asphalt fume and function, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., to achieve the effects of scientific and reasonable system structure, broad market application prospects, full utilization of resources and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

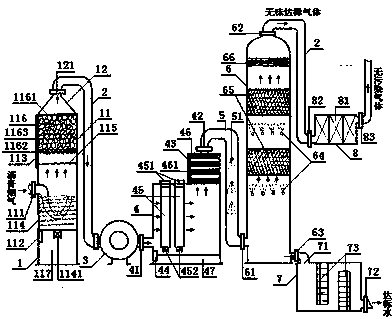

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0026] In the accompanying drawings, the multi-functional environment-friendly asphalt flue gas purification system of the present invention, the main body includes a dust treatment tower 1, a gas pipeline 2, an induced draft fan 3 and an oil filter and deodorization box 4, and is characterized in that it also includes a main gas Spray pipeline 5, turbulent-flow dynamic wave water film washing tank 6, sedimentation and oil-separating circulating water pool 7, and plasma oil fume purification and exhaust gas purification device 8, wherein: the main body of the dust treatment tower 1 is welded by steel plates, and is composed of A barrel-shaped tower body 11 with an input pipe interface A111 and a conical tower top 12 with an output pipe interface A121 are formed. The barrel body of the tower body 11 is provided with a control operation door A112 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com