Device and method capable of simulating oil displacement efficiencies of oil layers with different dip angles

A technology for oil displacement and oil layer application in the field of experimental devices for simulating the oil displacement effect of oil layers with different dip angles. It can solve the problems of no experimental devices and achieve the effect of large dip angle range, scientific and reasonable structure, and large angle change space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing:

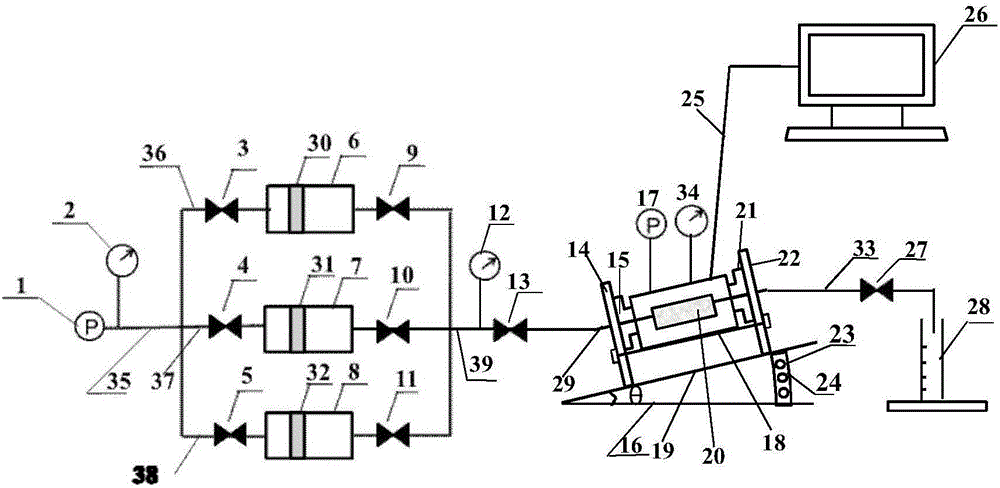

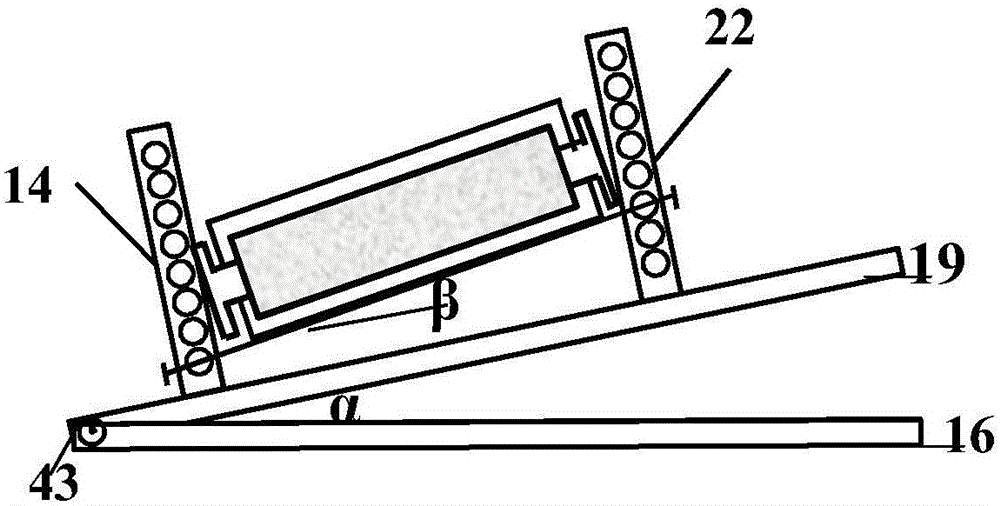

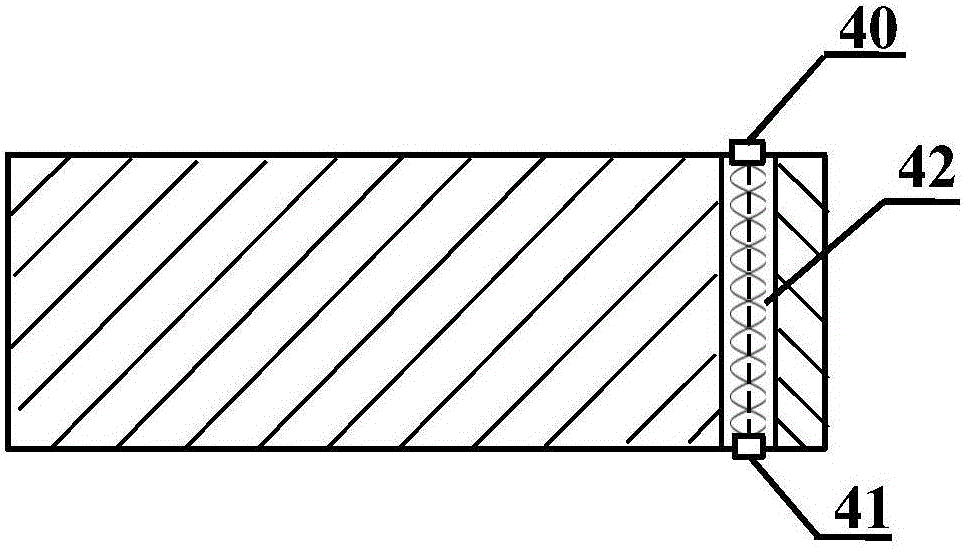

[0043] Depend on Figure 1 to Figure 7 As shown, this kind of device that can simulate the oil displacement effect of oil layers with different dip angles includes a constant speed displacement pump 1, an annular pressure pump 17, a first intermediate container 6, a second intermediate container 7, a third intermediate container 8, a A pressure gauge 2, a second pressure gauge 12, a third pressure gauge 34, an image analyzer 26, the first intermediate container inlet valve 3, the second intermediate container inlet valve 4, the third intermediate container inlet valve 5, the first intermediate container Outlet valve 9, second intermediate container outlet valve 10, third intermediate container outlet valve 11, intermediate container master control valve 13, core holder outlet valve 27, variable inclination angle core holder base plate 16, variable inclination angle core hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com