Material platform of wood drilling machine

A technology of drilling machine and material table, which is applied to drilling machines, wood processing appliances, manufacturing tools, etc., can solve the problems of inaccurate and convenient drilling processing, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

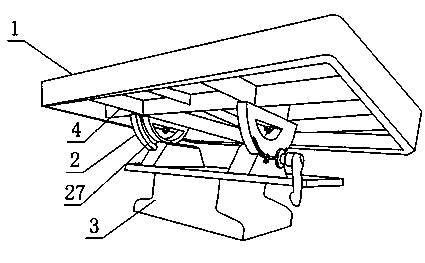

[0022] Figure 1 and figure 2 , the wood drilling machine material table provided by the present invention includes a platform body 1, a frame 3, and an angle adjustment part 2, and the upper and lower ends of the angle adjustment part 2 are fixedly connected to the platform body 1 and the frame 3 respectively;

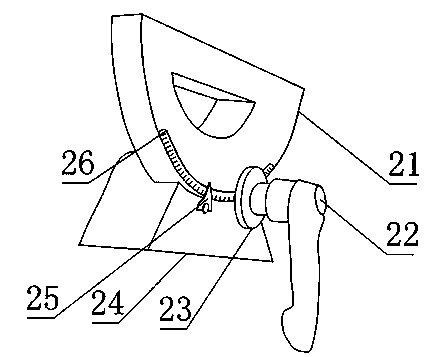

[0023] The angle adjustment part 2 includes an arc-shaped block 21 whose upper end is fixedly connected with the platform body 1, a compression bolt 22, and an arc-shaped block seat 24 whose lower end is fixedly connected with the frame 3. The upper end of the arc-shaped block seat 24 is provided with an arc shaped groove, the lower end of the arc-shaped block 21 is provided with an arc-shaped portion whose radian is consistent with the arc-shaped groove, the arc-shaped portion is located in the arc-shaped groove, the compression bolt 22 is threadedly connected with the arc-shaped block seat 24, and the arc-shaped The block 21 and the arc-shaped block seat 24 are fixe...

Embodiment 2

[0026] This embodiment is further limited on the basis of embodiment 1: as shown in Figure 1 and figure 2 , the arc-shaped block 21 is in the shape of a semi-disc with a notch upward, the arc-shaped groove on the arc-shaped block seat 24 runs through one side of the arc-shaped block seat 24, and the pressing bolt 22 is a single-headed bolt, on which the There is a flat pad 23, and one side of the flat pad 23 is in contact with the bolt cap of the compression bolt 22, and one side of the flat pad 23 is in contact with the arc block 21 and the arc block seat 24.

[0027] The arc-shaped block 21 and the arc-shaped block seat 24 of the above structural form are simple in structure, and are convenient for processing and manufacturing. The stressed area of the shaped block 21 is conducive to the stability of fixing the arc-shaped block 21 and the arc-shaped block seat 24 after the compression bolt 22 is locked.

[0028] The side surface of the arc block 21 is also provided with ...

Embodiment 3

[0031] This embodiment is further limited on the basis of embodiment 1: as shown in Figure 1 and figure 2 , in order to facilitate the adjustment and display of the inclination of the platform body 1, it also includes an angle scale 26 arranged on the arc block 21 and distributed around the arc portion and an angle pointer 25 fixed on the arc block seat 24.

[0032] In order to save the material consumption of the platform body 1 , it also includes a sheet-shaped rib 4 arranged at the lower part of the platform body, and the rib 4 is perpendicular to the working plane of the platform body 1 .

[0033] In order to increase the carrying capacity of the platform body 1 , there are more than one angle adjustment parts 2 , and the angle adjustment parts 2 are parallel to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com