Textile thread traction device and traction method

A traction device and textile thread technology, which is applied in the directions of transportation and packaging, thin material handling, and filamentary material transportation, etc., can solve the problem that the guide frame and the textile thread are easy to wear out the textile thread, the constant universality of the traction wheel is not strong, and the There is no adjustment and other problems, to achieve the effect of improving toughness, wide applicability, and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

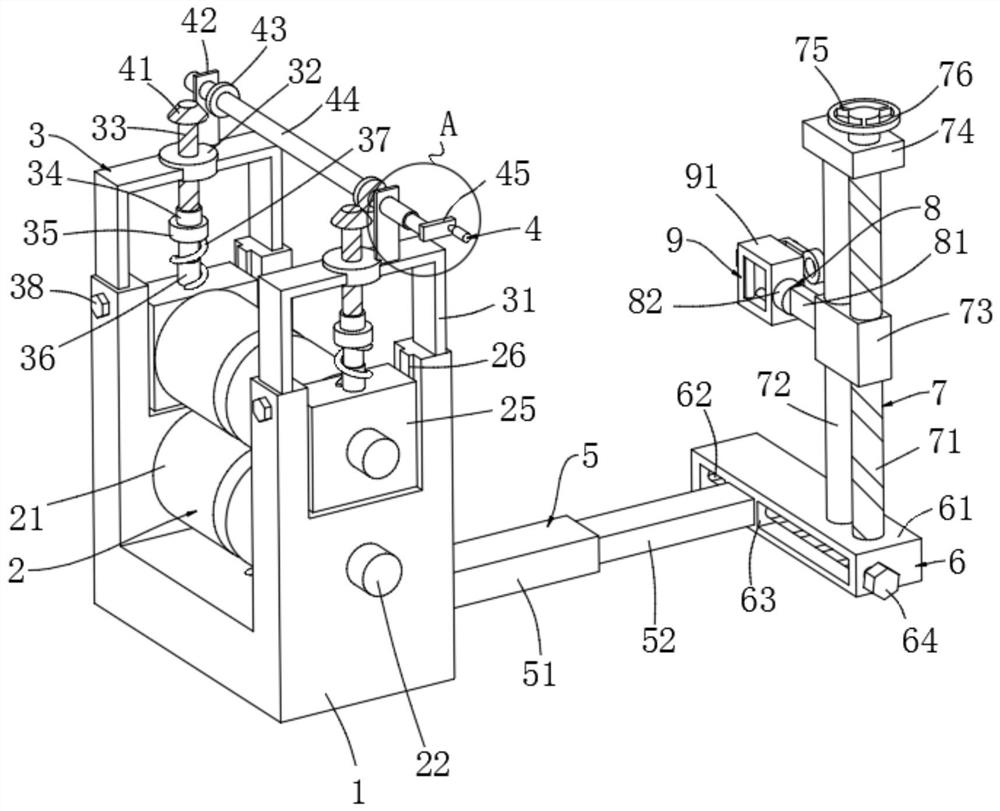

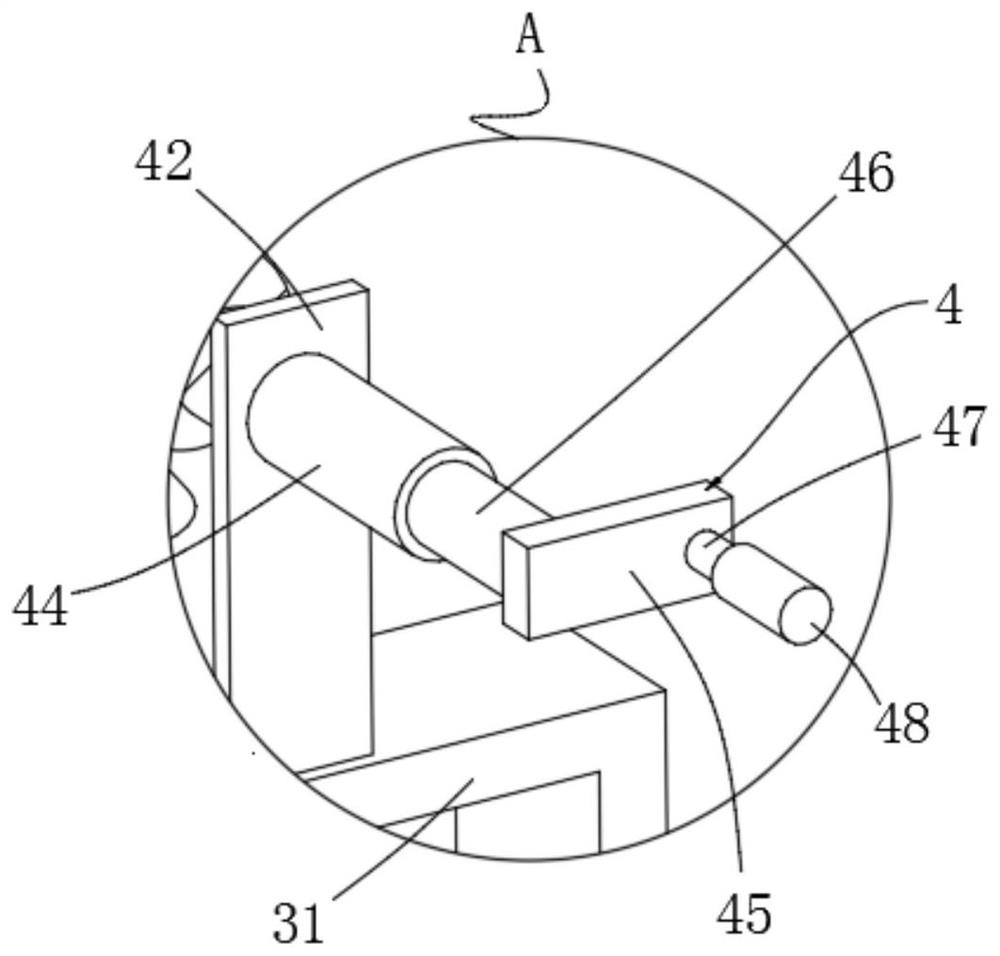

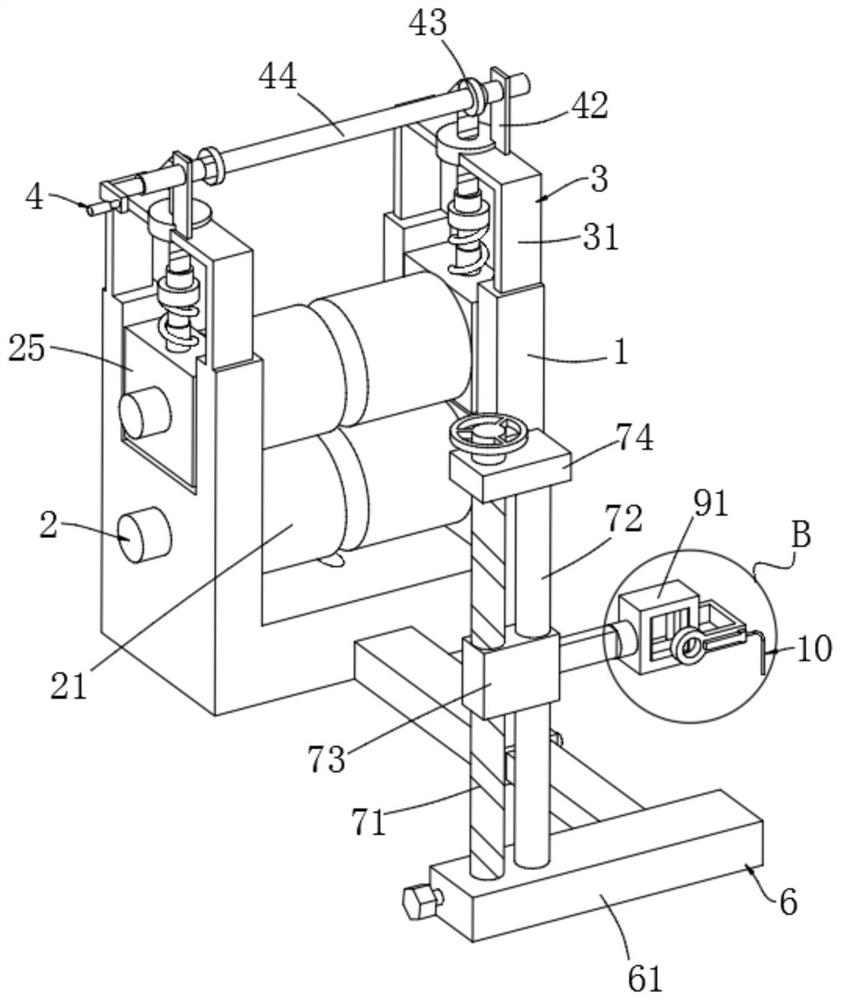

[0046] Example 1, please refer to Figure 1-10 , this embodiment provides a technical solution: a textile thread traction device, including a U-shaped frame 1, a traction power unit 2, a roller spacing adjustment unit 3, a roller spacing control unit 4, a distance adjustment unit 5, and a lateral adjustment unit 6. Height adjustment unit 7, corner adjustment unit 8 and rolling guide unit 9;

[0047] The two ends of the U-shaped frame 1 are respectively provided with slots, the traction power unit 2 is installed in the slot of the U-shaped frame 1, the roller spacing adjustment unit 3 is also installed on the U-shaped frame 1, and the roller spacing adjustment unit 3 is installed on the U-shaped frame 1. A roller spacing control unit 4 is installed, and one side of the U-shaped frame 1 is connected to a lateral adjustment unit 6 through a distance adjustment unit 5, and a height adjustment unit 7 is installed on the lateral adjustment unit 6, and the height adjustment unit 7 is...

Embodiment 2

[0071] Example 2, please refer to Figure 4 , this embodiment provides a technical solution: a textile thread traction device, the structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that it also includes a static electricity deriving unit 10, and the static electricity deriving unit 10 includes a side bending rod for installation 101, lead-out metal ring 102, metal conductive rod 103, conductive connection block 104 and grounding wire 105, the side of square frame 91 is connected with lead-out metal ring 102 by installing side bending rod 101, lead-out metal ring 102 is positioned at the front of square frame 91 , the lead-out metal ring 102 is connected to one end of the metal conductive rod 103 , and the other end of the metal conductive rod 103 is connected to one end of the ground wire 105 through the conductive connection block 104 . In order to prevent the textile thread from contacting the rolling shaft 95 with static electricity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com