Hydraulic automatic leveling system and leveling method of seabed drilling rig

An automatic leveling and drilling rig technology, applied in fluid pressure actuating devices, drilling equipment, earthwork drilling, etc., can solve problems such as poor stability and anti-overturning ability, complex control system, etc., and achieve convenient control and scientific and reasonable structure. , the effect of fast leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

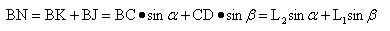

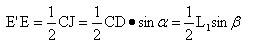

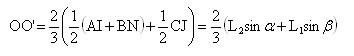

[0034] Embodiment 1: The hydraulic automatic leveling system of a kind of seabed drilling rig of the present invention, its structure is as follows figure 1 , 2 shown. It includes a support plate 1, a boom 2, a chain 3, a hydraulic cylinder leg 4, a base 5 and a hydraulic control system.

[0035] Support plate 1: directly in contact with the seabed surface, the function is to decompose the gravity of the entire drilling rig.

[0036] Boom 2: used to connect hydraulic cylinder legs, base and support plate.

[0037] Chain 3: used to constrain the degree of freedom of the rotation of the support plate.

[0038] Hydraulic cylinder outrigger 4: The three hydraulic cylinder outriggers 4 have the same structure and are arranged in an equilateral triangle on the same horizontal plane. Leveling.

[0039] Base 5: It is the foundation of the entire leveling system, and its main function is to connect and support the entire drilling rig.

[0040] Hydraulic system: Considering the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com