Clay screening and crushing integrated equipment

A screening and clay technology, which is applied in chemical instruments and methods, smoke and dust removal, cleaning methods and utensils, etc., can solve the problems of dust control and treatment, low screening efficiency, low crushing efficiency, etc. Achieve the effects of reducing secondary pollution, simplifying the screening and crushing process, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to more clearly illustrate the technical solutions in the embodiments of this patent or the prior art, the following will briefly introduce the accompanying drawings required in the description of the embodiments or prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative effort.

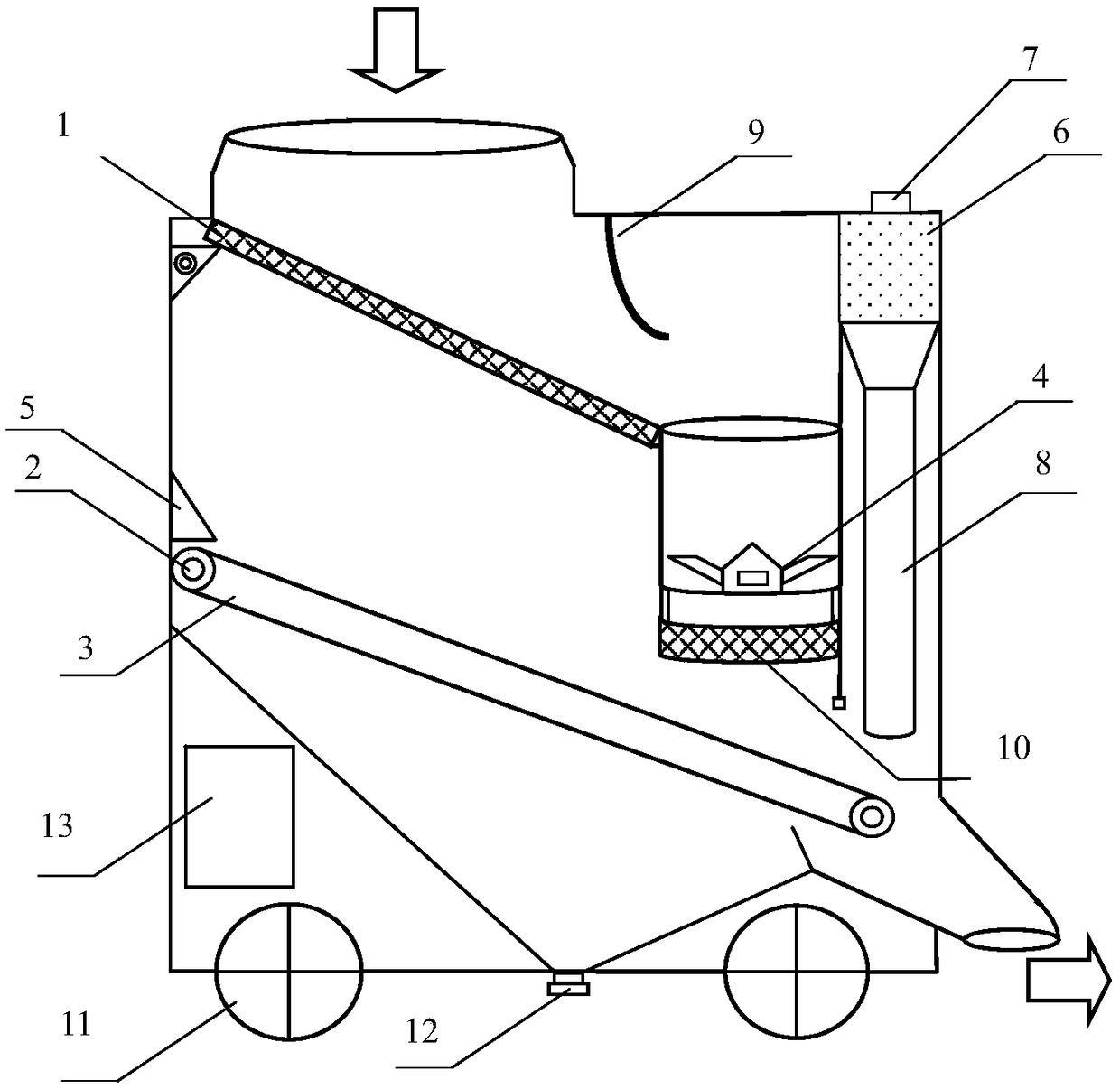

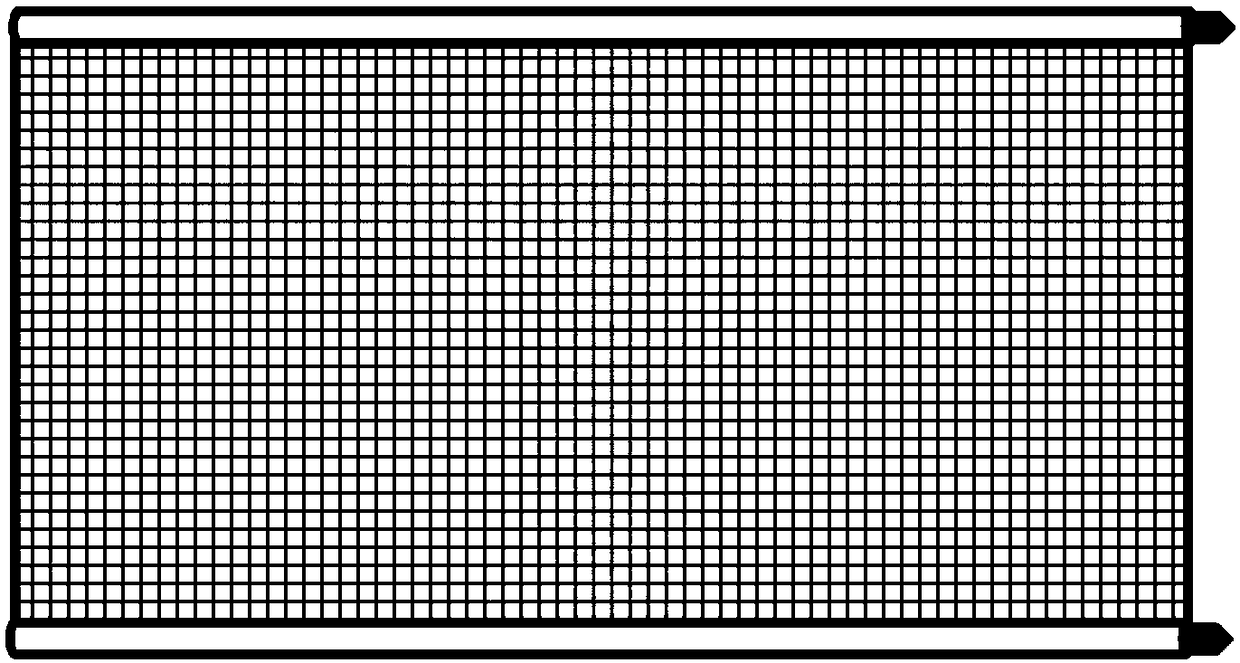

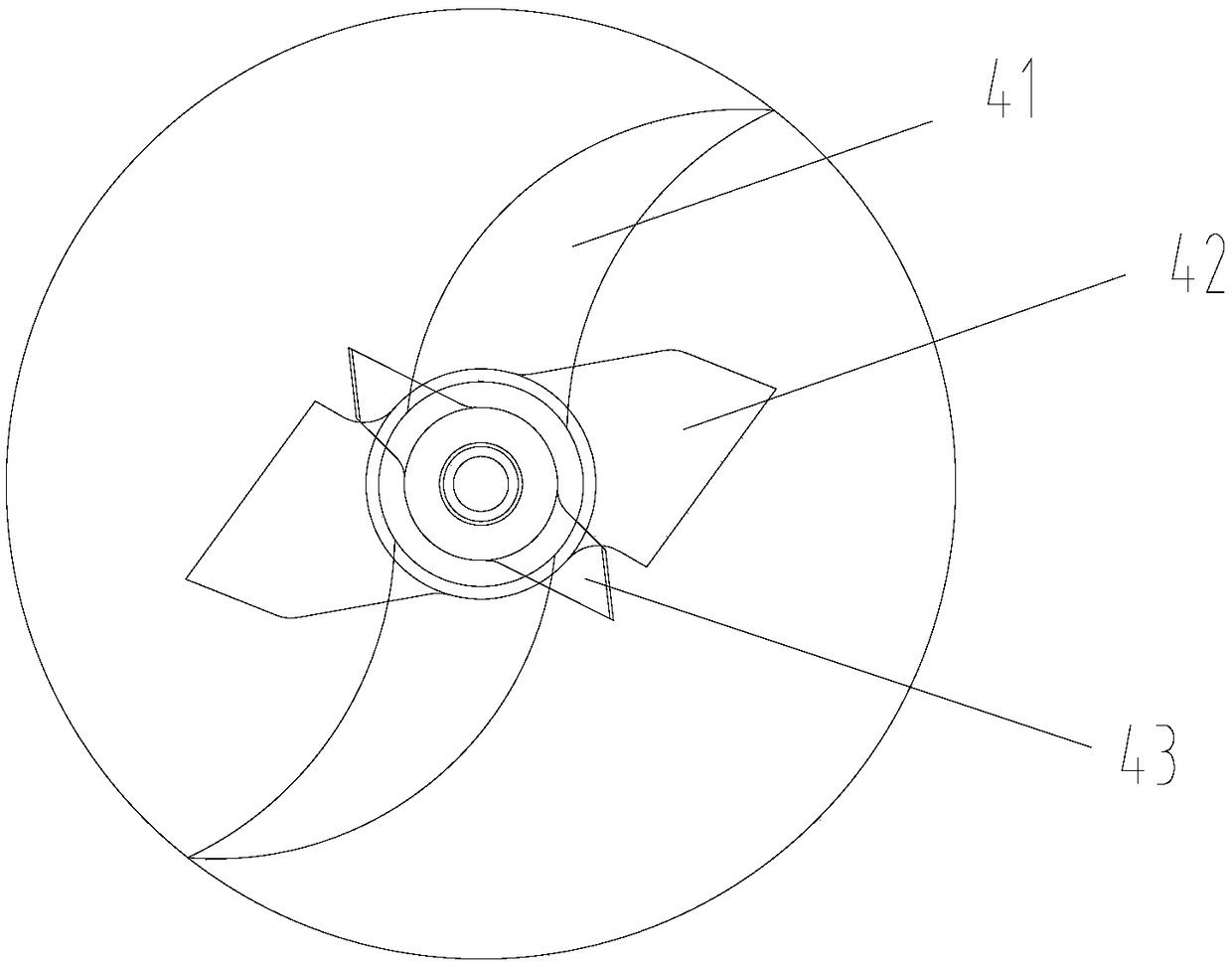

[0027] Such as Figure 1 to Figure 4 As shown, an integrated clay screening and crushing equipment includes a pre-screen 1 installed in the housing, a cyclone crushing device 4, a dust collection device 6, and a material transmission device 3. The feed inlet is located on the top of the shell, and the pre-screening plate 1 is connected to the cyclone crushing device 4. The material larger than the pre-screening particle size will smoothly fall into the cyclone crushing device 4 with the slope for the next cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com