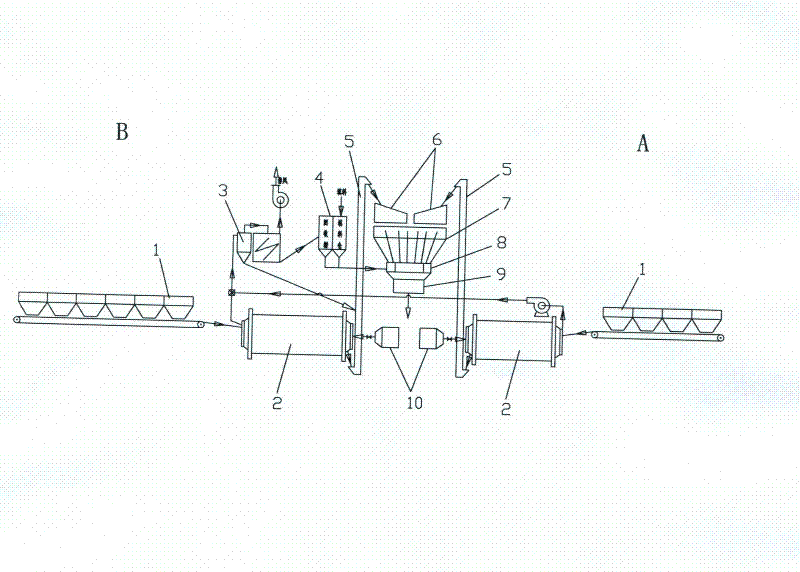

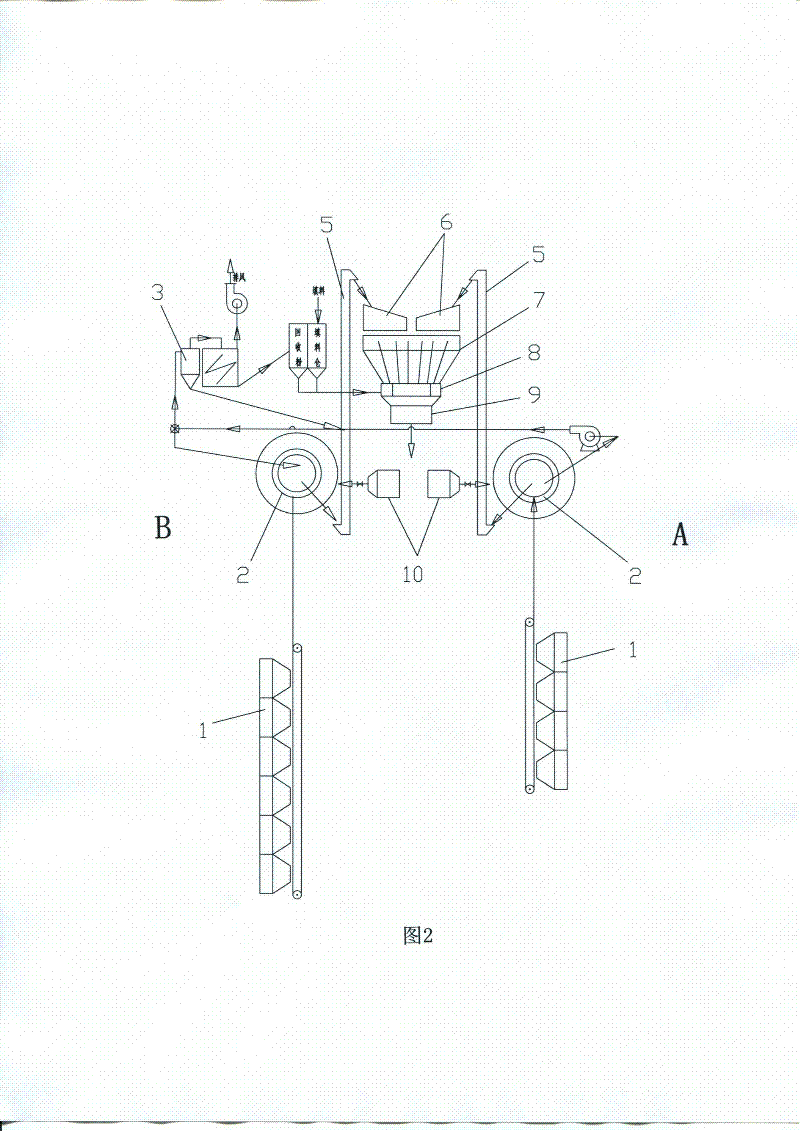

Separation feeding-type hot mix intermittent asphalt mixture blending machine and production technology therefor

An asphalt mixture, intermittent technology, used in roads, road repair, roads, etc., can solve the problems of insufficient cold material storage space, increase single machine output and production efficiency, reduce secondary transportation costs, and improve screening. The effect of improving capacity and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

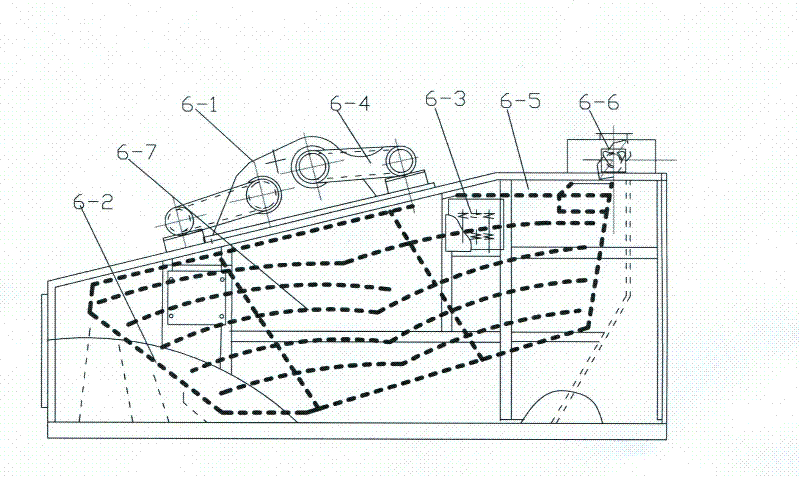

Method used

Image

Examples

example 1

[0046] Example 1: A project AC-16 mixture uses four kinds of aggregates, namely crushed stone 9.5-19mm (A material), crushed stone 4.75-9.5mm (B material), crushed stone 2.36-4.75mm (C material), mechanism Sand 0-2.36mm (D material)

[0047] grouping:

[0048] The cold aggregate is divided into two groups according to the specifications and sizes: the first group is A material and C material; the second group is B material and D material.

[0049] One group contains the finest cold aggregate, corresponding to No. A feeding system; the other group is coarse cold aggregate, corresponding to No. B feeding system.

[0050] Corresponding to No. A feeding system cold material group: crushed stone 4.75-9.5mm (B material), machine-made sand 0-2.36mm (D material)

[0051] Corresponding to No. B feeding system cold material group: crushed stone 9.5-19mm (A material), crushed stone 2.36-4.75mm (C material)

[0052] Mesh selection:

[0053] The interval between material B and material...

example 2

[0056] Example 2: A project AC-25 mixture uses six kinds of aggregates, namely crushed stone 19-31.5mm (material A), crushed stone 9.5-19mm (material B), crushed stone 4.75-9.5mm (material C), crushed stone Stone 2.36-4.75mm (D material), machine-made sand 0-2.36mm (E material), natural sand 0-4.75mm (F material).

[0057] grouping:

[0058] Machine-made sand 0-2.36mm (material E) and natural sand 0-4.75mm (material F) with similar specifications are counted as one and placed in the same group, then

[0059] The cold aggregate is divided into two groups according to the specifications and sizes: the first group A feed system is A material, C material, E material and F material; the second group B feed system is B material and D material.

[0060] The ratio of E material and F material is controlled from the cold material feeding system.

[0061] Mesh selection:

[0062] The first group A No. feeding system, the maximum particle size is 31.5mm, the intermittent interval is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com