Film hand lifting rolling bag and production method thereof

A technology of continuous roll bag and film bag, which is applied in the field of film portable continuous roll bag and its production. It can solve the problems of no handle, not easy to separate, easy to separate heat seals, etc., to save materials, easy to use, and not easy to leak bottom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

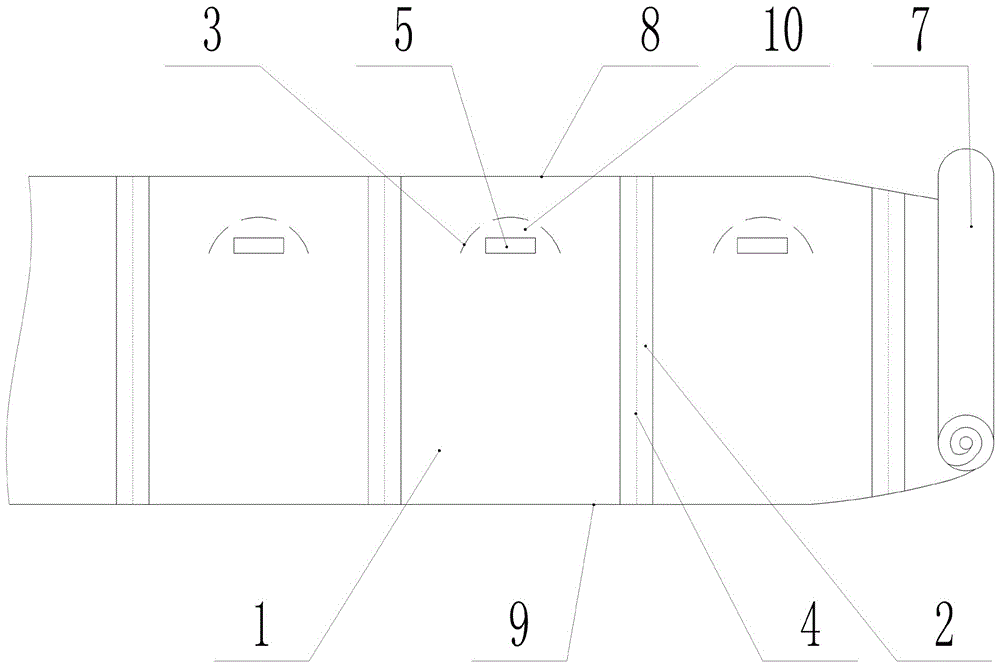

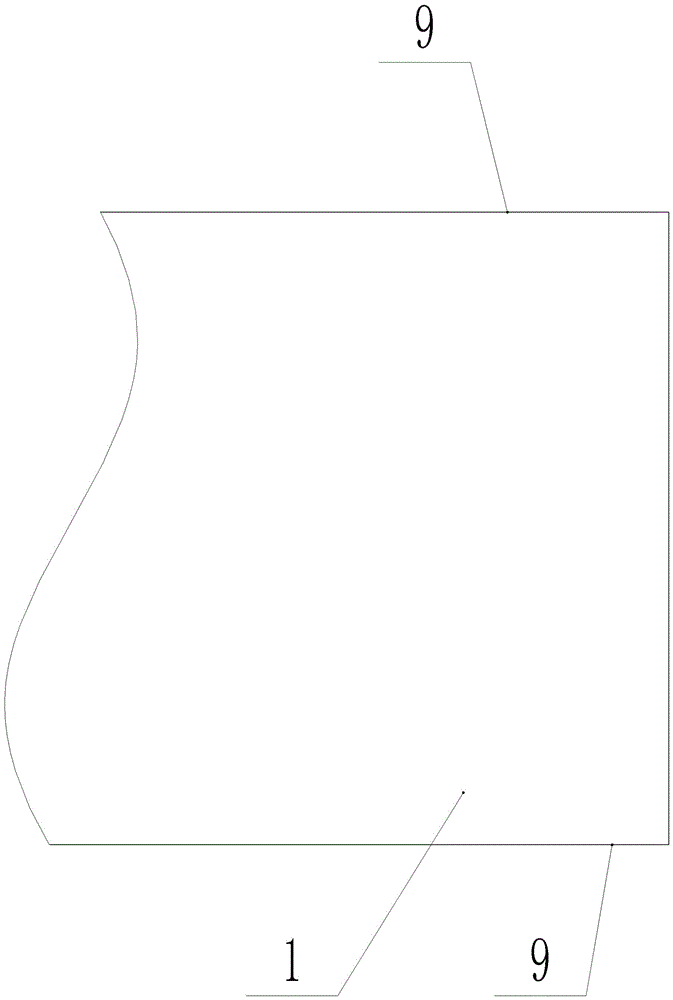

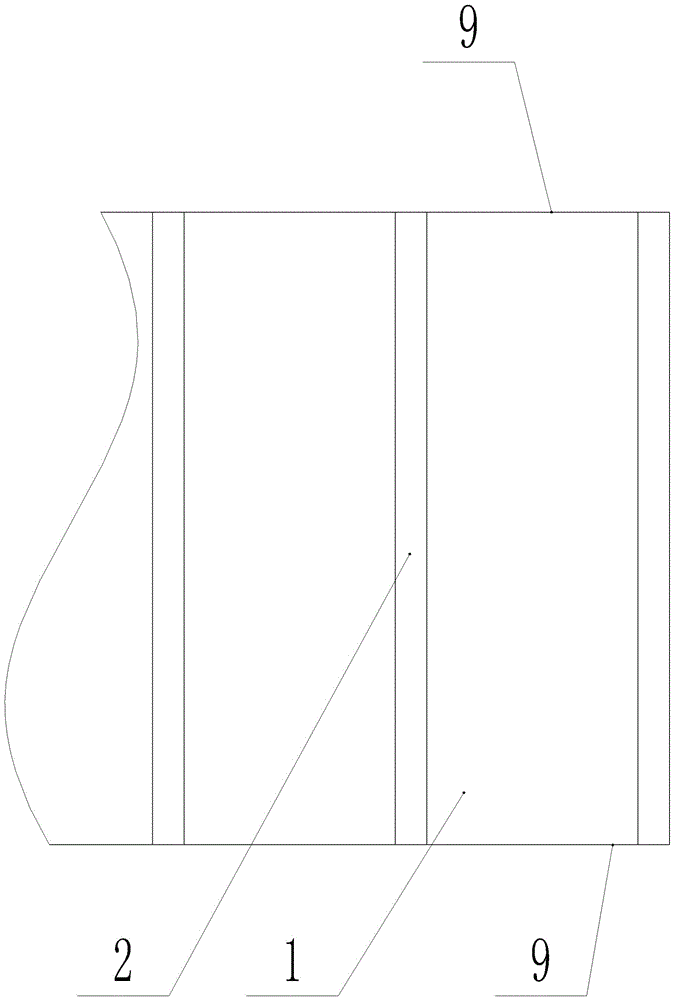

[0027] Such as figure 1 As shown, a film portable continuous roll bag includes a plurality of film bag bodies 1 connected in sequence and rolled into a reel. A break line 4 is provided between adjacent bag bodies 1, and two adjacent film bag bodies 1 is the side connection, the bottom 9 of the bag body 1 is the double-folded edge, the bottom 9 is the bottom of the film bag, the sides on both sides of the bag 1 are the heat-sealing edges 2, and the upper part of the bag 1 is the mouth 8. The arc-shaped broken line 3 provided in the lower part of the mouth 8 is the handle.

[0028] The arc-shaped breaking line 3 is 4-6 cm away from the bag opening, which is 5 cm in this example.

[0029] The two sides of the bag body below the arc-shaped breaking line 3 are hinged sheets 10, and the outer side of one hinged sheet 10 is a liquid adhesive sheet 5.

[0030] The arc-shaped broken line 3 is divided into three parts, the distance between two adjacent parts is 0.5-1.0 cm, and the distance in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com