PVC folder multifunctional production line and production technology

A multi-functional, production line technology, applied in printing technology, metal processing, rotary printing machines, etc., can solve the problems of single production mode and small application range, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

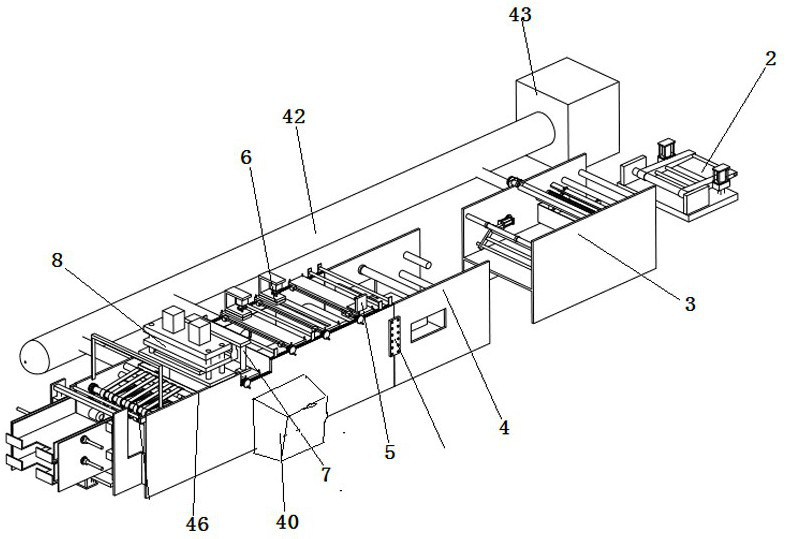

[0035] Below we will further illustrate a kind of PVC folder multifunctional production line and production process of the present invention in conjunction with the accompanying drawings.

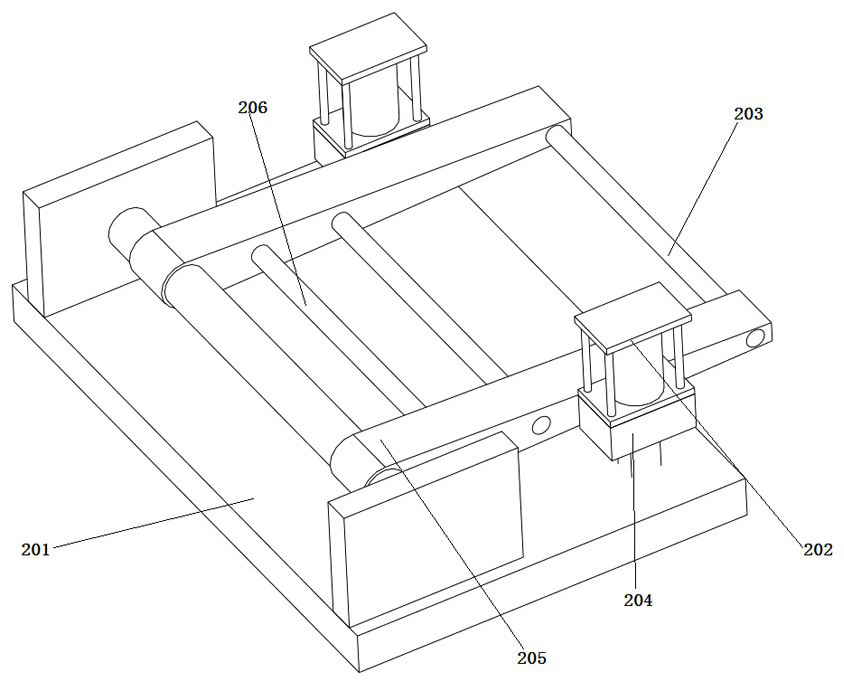

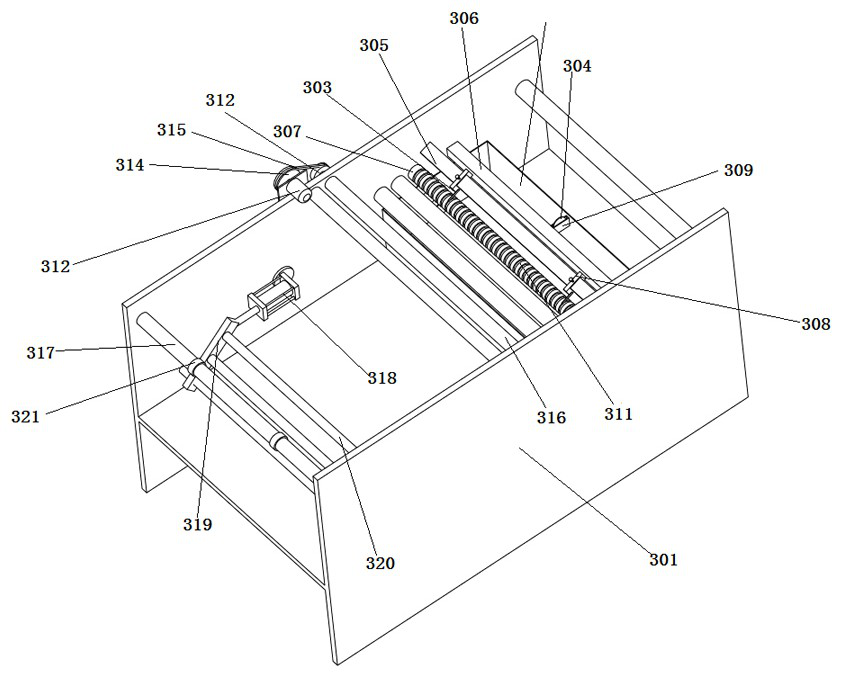

[0036] combine Figure 1-12 As shown, a PVC folder multifunctional production line in this embodiment includes a feeding device 2, a base 1, a pretreatment device 3, a folding device 4, a bronzing device 5, a punching device 6, an ultrasonic welding device 7 and a blanking device Device 8; it is characterized in that a console 40, several guide shafts 407 and a rack 45 are installed on the base 1; an adjustment plate 46 is installed on the rack 45; the bronzing device 5, the punching device 6 , the ultrasonic welding device 7 and the blanking device 8 are all fixed on the base through the adjustment plate 46; the folding device includes a folding device base 401; the folding device base 401 is equipped with a fixed connecting plate 416, a gear bar 402 and several The magnet fixing plate 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com