Reciprocating type vibrating screen

A vibrating sieve and reciprocating technology, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems of unqualified sieving materials, low utilization rate of sieve surface, and affecting sieving effect, so as to increase the use area, Improve the screening effect and reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

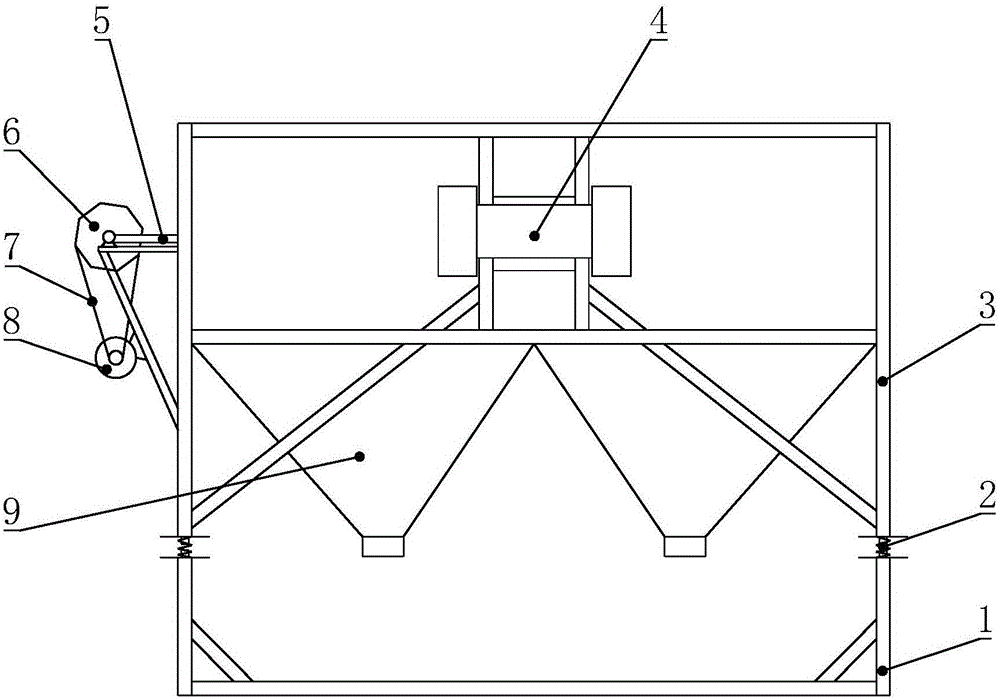

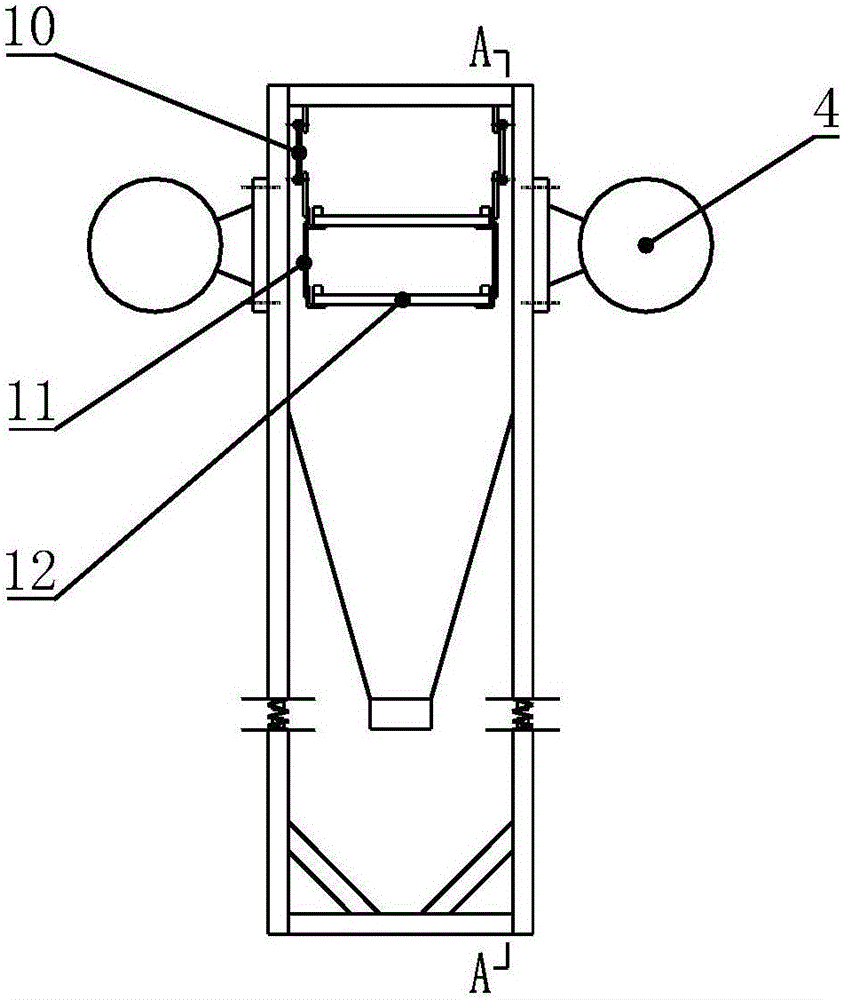

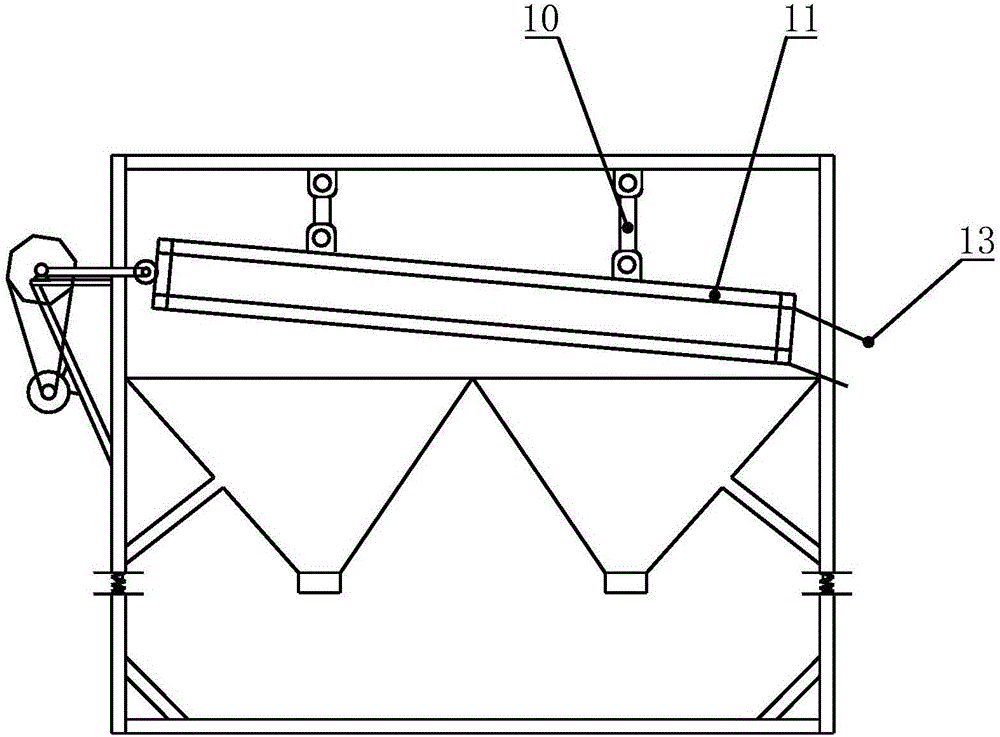

[0027] Such as figure 1 As shown, a reciprocating vibrating screen includes a base 1, a spring 2, a frame 3, a vibration motor 4, a reciprocating drive device, a screen frame 11 and a combined screen 12, and the frame 3 is welded by square tubes Frame structure, the frame 3 and the base 1 are connected by a spring 2, which divides the equipment into upper and lower parts. The spring 2 can be an ordinary steel wire rigid spring 2, or a rubber air spring 2. The rubber air spring 2 can be adjusted by adjusting the internal Pressure, can get different load capacity, so it can meet the needs of various loads: the rubber air spring 2 is light in weight and has a long service life. Such as figure 2 As shown, a vibrating motor 4 is respectively installed on the opposite two sides of the frame 3, and the two vibrating motors 4 have the same type and opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com