Ultraviolet screening agent, preparation method thereof, polylactic acid film containing ultraviolet screening agent and preparation method of polylactic acid film

A technology of shielding agent and ultraviolet rays, applied in the direction of flat products, other household appliances, fibrous fillers, etc., can solve the problems of not involving film products, not involving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

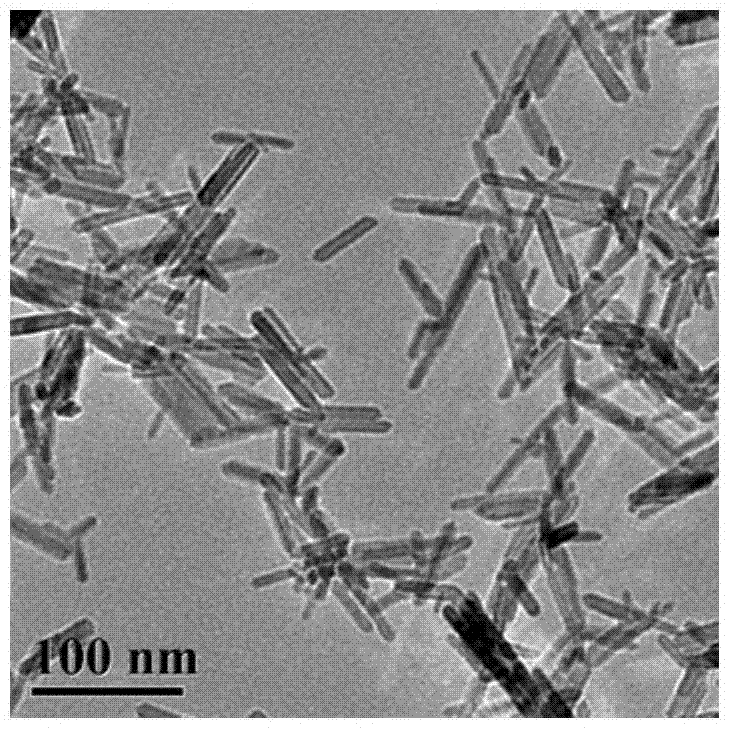

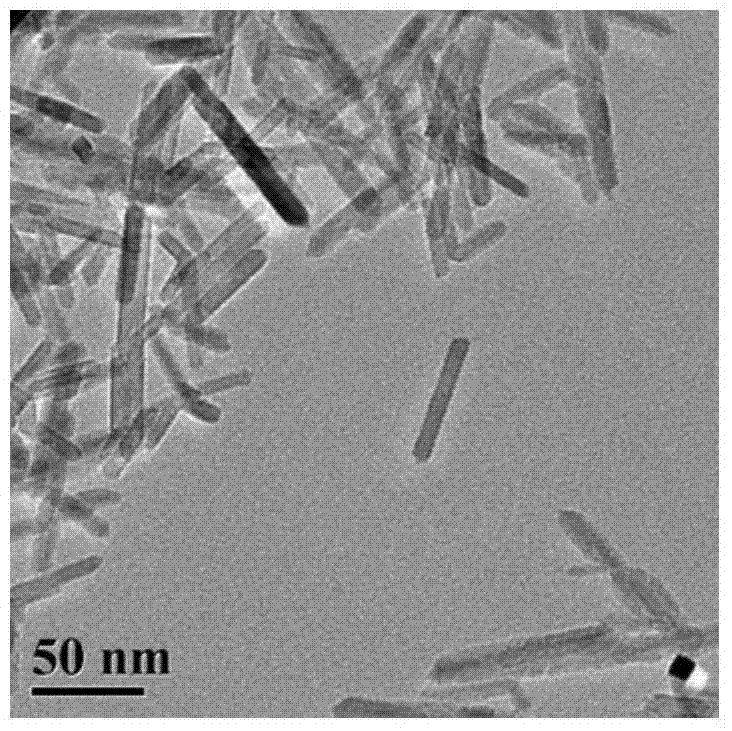

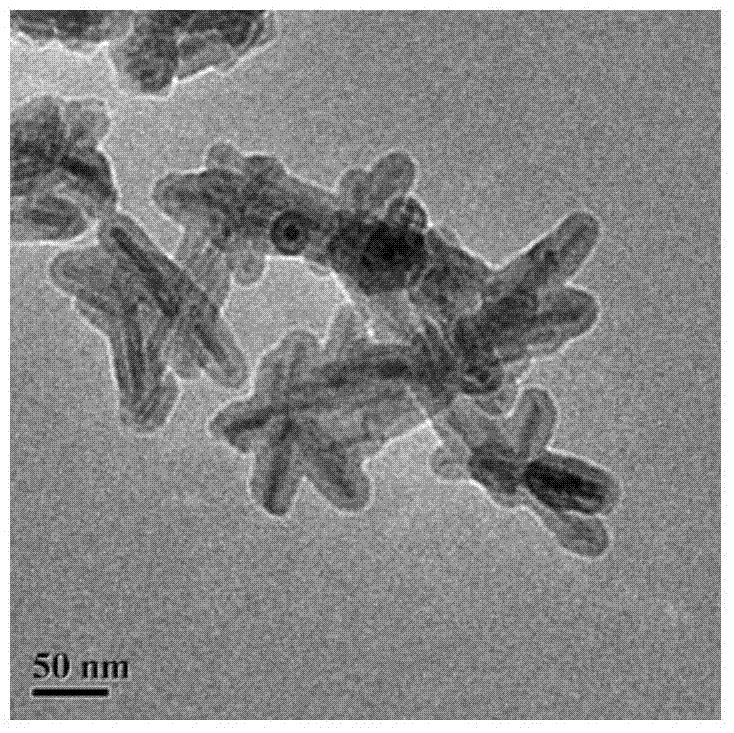

Image

Examples

Embodiment 1

[0141] (1) Weigh 2g of nano-titanium dioxide and add it to 200mL of isopropanol, stir and ultrasonically oscillate for 60 minutes, adjust the system to PH=10 with ammonia water, add 6mL of tetraethyl orthosilicate, and stir at 30°C for 30 hours. , filtered, washed three times with deionized water, and dried at 60°C to obtain an ultraviolet shielding agent;

[0142] (2) Dry the polylactic acid resin at 80°C for 12 hours;

[0143] (3) Add 98.7g of dried polylactic acid resin, 1g of UV shielding agent prepared in step 1, and 0.3g of antioxidant 1010 into a high-speed mixer, mix evenly at 25°C, and mix at a high speed of 200 rpm Mix for 5 minutes;

[0144] (4) Add the product mixed in step 3 into a twin-screw extruder, and then cool and granulate after melt extrusion to obtain a masterbatch of polylactic acid composite material. The process is as follows: the temperature in the first zone is 180°C, and the temperature in the second zone is The temperature is 185°C, the temperatu...

Embodiment 2

[0147](1) Weigh 20g of nano-titanium dioxide and add it to 400mL ethanol solution, stir and ultrasonically oscillate for 60 minutes, adjust the system to PH=11 with sodium hydroxide solution, add 10mL tetraethyl orthosilicate, and stir at 40°C for 30 minutes Hours, filter under normal pressure, wash with deionized water, and dry at 150°C to obtain an ultraviolet shielding agent;

[0148] (2) Dry the polylactic acid resin at 70°C for 10 hours;

[0149] (3) Add 97.7g of dried polylactic acid, 2g of ultraviolet shielding agent prepared in step 1, and 0.3g of antioxidant 1010 into a high-speed mixer and mix evenly at 25°C, and mix at a high speed of 200 rpm for 5 minute;

[0150] (4) Add the raw materials mixed in step 3 into a twin-screw extruder, and then cool and granulate after melt extrusion to obtain polylactic acid composite material master batches. The process is as follows: the temperature in the first zone is 180°C, and the temperature in the second zone The temperatur...

Embodiment 3

[0153] (1) Weigh 10g of nano-titanium dioxide and add it to 100mL of isopropanol solution, stir and ultrasonically oscillate for 60 minutes, adjust the system to PH=9 with potassium hydroxide solution, add 5mL of methyl orthosilicate, and stir at 60°C to keep the temperature React for 30 hours, filter under reduced pressure, wash with deionized water for 4 times, and dry at 100°C to obtain an ultraviolet shielding agent;

[0154] (2) Dry the polylactic acid resin at 90°C for 10 hours;

[0155] (3) Add 99g of dried polylactic acid, 0.5g of the UV shielding agent prepared in step 1, and 0.3g of antioxidant 1010 into a high-speed mixer and mix evenly at 25°C, and mix at a high speed of 200 rpm for 5 minute;

[0156] (4) Add the raw materials mixed in step 3 into a twin-screw extruder, and then cool and granulate after melt extrusion to obtain polylactic acid composite material master batches. The process is as follows: the temperature in the first zone is 180°C, and the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com