Disposal method for reusing highly-compound construction waste

A construction waste and treatment method technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems that affect the recycling of construction waste, construction waste is not classified, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

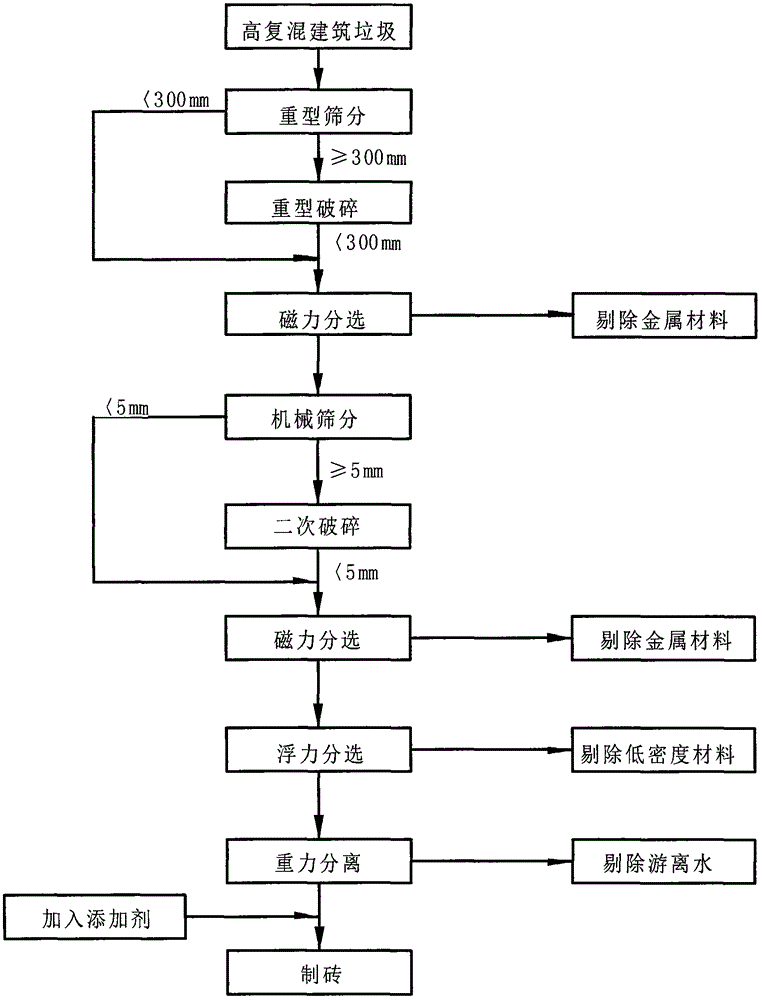

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Experimental comparison method in the embodiment: get from the highly complex construction waste of Longshan dumping ground in Korla City, Xinjiang, its main components are preliminarily estimated as follows: 30-35% of wall waste, 5-7% of bridge concrete, broken old bricks Blocks, ceramics, glass are about 35-40%, and the rest are construction dregs, iron wire steel bars, bamboo and wood fragments, plastics, etc.; the largest bridge concrete body has a diameter of 1.8 meters. The construction waste belongs to highly compound construction waste such as concrete, wall, ceramics, dregs, steel bars, wood, asphalt, plastic, etc. of demolished buildings with different sources, types, components, shapes, and properties. Adopt technology treatment process of the present invention as follows:

[0021] 1. Use a forklift to import the construction waste in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com