Rapeseed mechanical screening facility

A screening equipment and mechanical technology, applied in the fields of sieving, fat oil/fat production, solid separation, etc., can solve the problems of difficult to finely screen rapeseed and laborious screening of rapeseed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

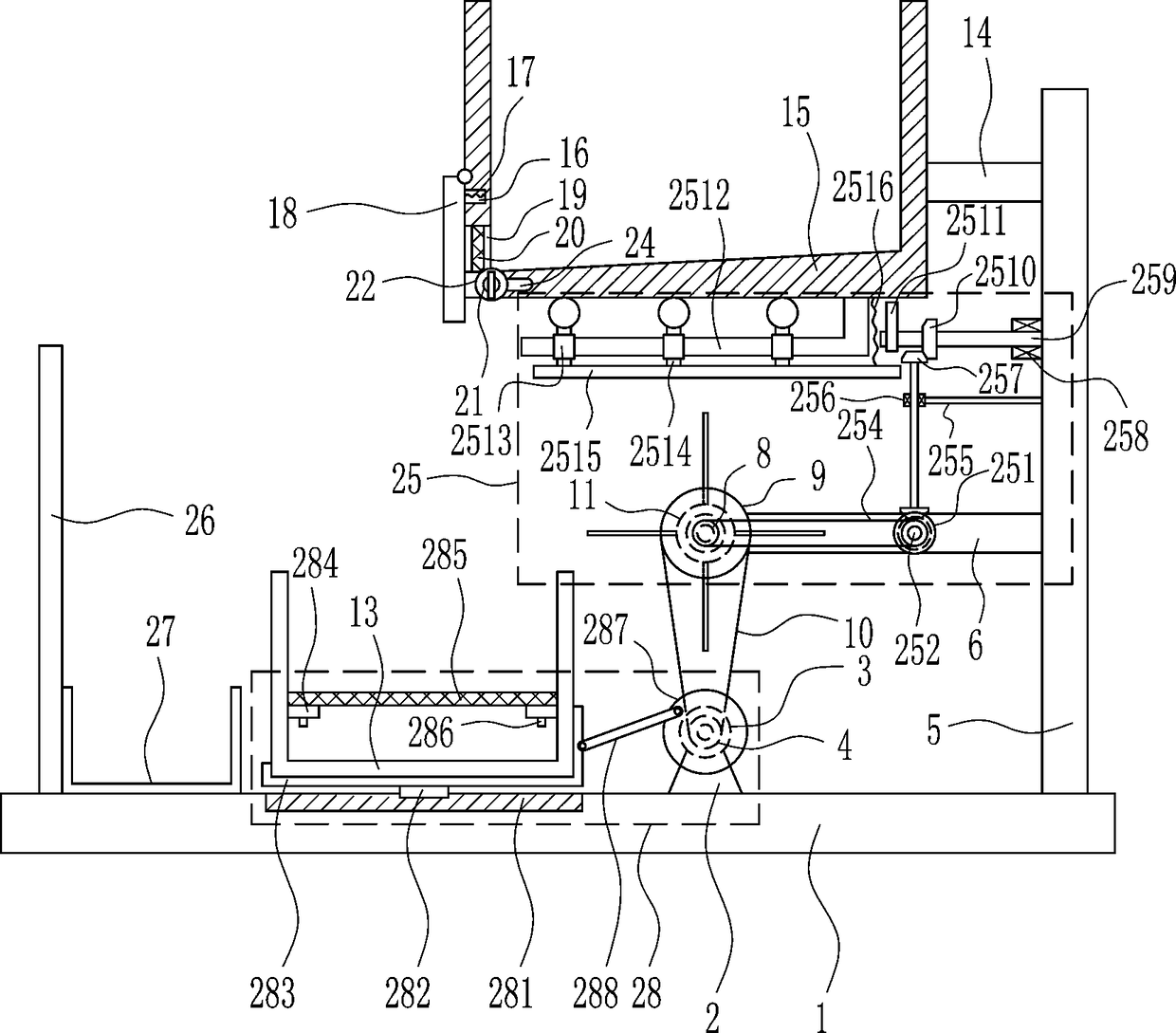

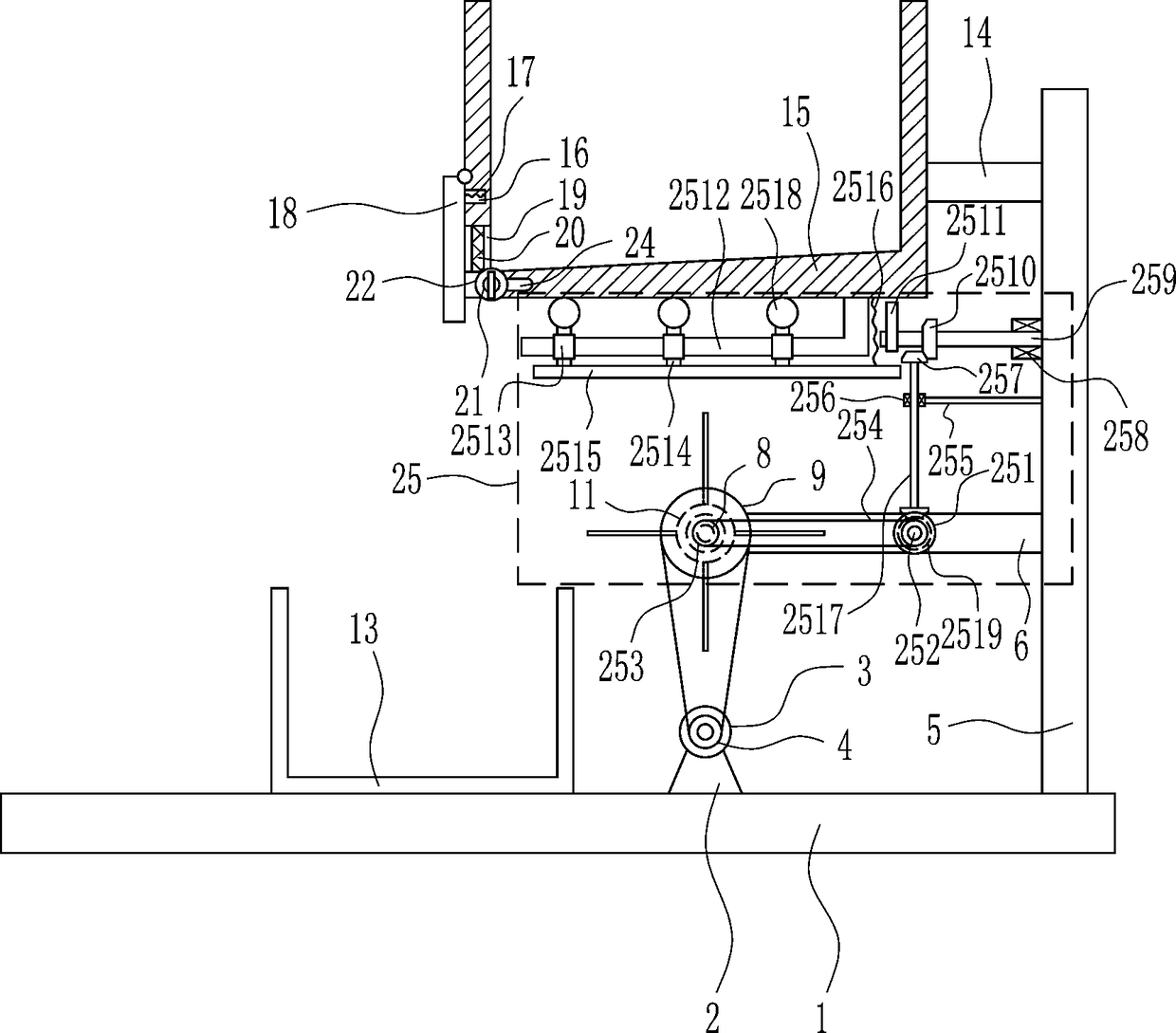

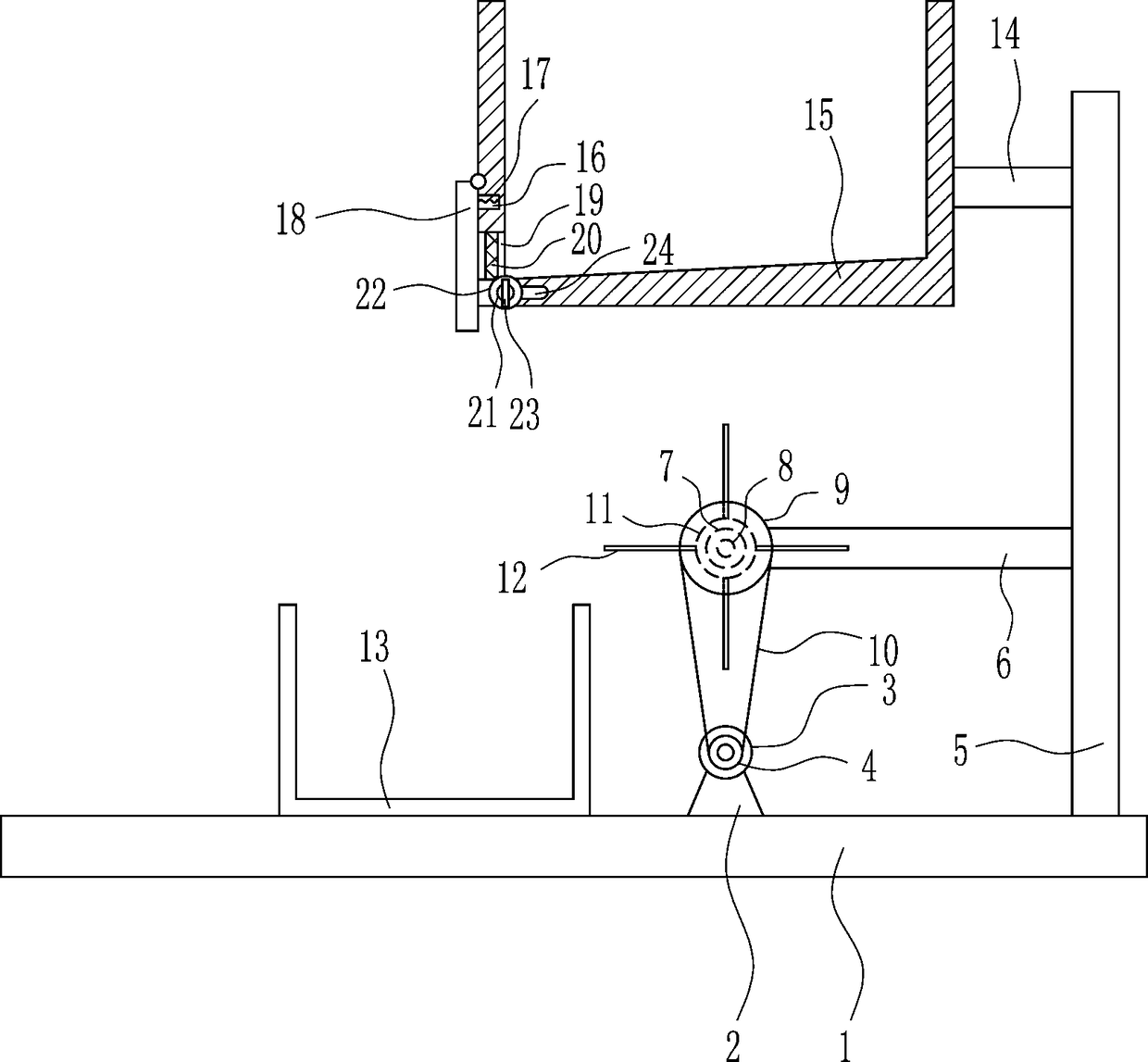

[0023] A rapeseed mechanical screening equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a mounting seat 2, a motor 3, a small pulley 4, a bracket 5, a first mounting plate 6, a first bearing seat 7, a first rotating shaft 8, a large pulley 9, a first flat belt 10, a round Tube 11, thin plate 12, first collection frame 13, pole 14, frame body 15, first spring 17, first baffle plate 18, small net plate 20, bolt 22, booster block 23 and push rod 24, bottom plate 1 top The right side is provided with mounting base 2, and mounting base 2 is provided with motor 3, and the output shaft of motor 3 front side is provided with small pulley 4, and bottom plate 1 top right side is provided with support 5, and support 5 is positioned at mounting base 2 right, The lower part of the left side of the bracket 5 is provided with a first mounting plate 6, and the left portion of the first mounting plate 6 is provided with a first bearing seat 7, and the first bearing seat 7...

Embodiment 2

[0025] A rapeseed mechanical screening equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a mounting seat 2, a motor 3, a small pulley 4, a bracket 5, a first mounting plate 6, a first bearing seat 7, a first rotating shaft 8, a large pulley 9, a first flat belt 10, a round Tube 11, thin plate 12, first collection frame 13, pole 14, frame body 15, first spring 17, first baffle plate 18, small net plate 20, bolt 22, booster block 23 and push rod 24, bottom plate 1 top The right side is provided with mounting base 2, and mounting base 2 is provided with motor 3, and the output shaft of motor 3 front side is provided with small pulley 4, and bottom plate 1 top right side is provided with support 5, and support 5 is positioned at mounting base 2 right, The lower part of the left side of the bracket 5 is provided with a first mounting plate 6, and the left portion of the first mounting plate 6 is provided with a first bearing seat 7, and the first bearing seat 7...

Embodiment 3

[0028] A rapeseed mechanical screening equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a mounting seat 2, a motor 3, a small pulley 4, a bracket 5, a first mounting plate 6, a first bearing seat 7, a first rotating shaft 8, a large pulley 9, a first flat belt 10, a round Tube 11, thin plate 12, first collection frame 13, pole 14, frame body 15, first spring 17, first baffle plate 18, small net plate 20, bolt 22, booster block 23 and push rod 24, bottom plate 1 top The right side is provided with mounting base 2, and mounting base 2 is provided with motor 3, and the output shaft of motor 3 front side is provided with small pulley 4, and bottom plate 1 top right side is provided with support 5, and support 5 is positioned at mounting base 2 right, The lower part of the left side of the bracket 5 is provided with a first mounting plate 6, and the left portion of the first mounting plate 6 is provided with a first bearing seat 7, and the first bearing seat 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com