Vibration pump type vibration screening mechanism of vibration pump type peanut cleaner

A vibrating screening and vibrating pump technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of harsh working environment, uneven vibration, high labor intensity, etc., and achieve good screening effect, improved efficiency, and uniform vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

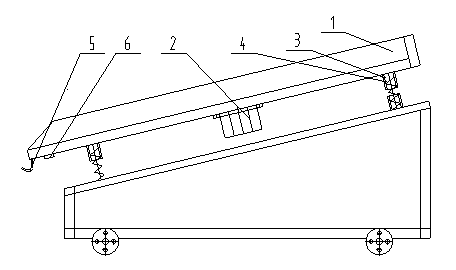

[0014] As shown in the figure, the vibrating pump type peanut cleaning machine vibrating pump type vibrating screening mechanism includes a vibrating screen 1, a vibrating pump 2, a spring 3, a spring seat 4, a bagging hook 5 and an outlet 6 for unqualified small fruits; The pump 2 is installed in the middle of the bottom of the vibrating screen 1. There are spring seats 4 on both sides of the bottom of the vibrating screen 1. Springs 3 are installed on the spring seats 4. The end of the vibrating screen 1 is provided with a bagging hook 5. Behind the bagging hook 5 Open the export of unqualified small fruit 6.

[0015] The vibrating pump type vibrating screening mechanism of the vibrating pump type peanut cleaning machine of the present invention, the peanuts coming from the fruit outlet of the peanut lifting conveying mechanism of the peanut cleaning machine fall into the vibrating sieve 1, and the vibrating sieve 1 is placed in the vibrating pump 2 Vibrates up and down unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com