High-pressure and high-efficiency roller press grinding system with screening device

A screening device and roller press technology, applied in grain processing and other directions, can solve the problems of high energy consumption, low efficiency and backwardness, and achieve the effect of reducing system energy consumption and unique technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

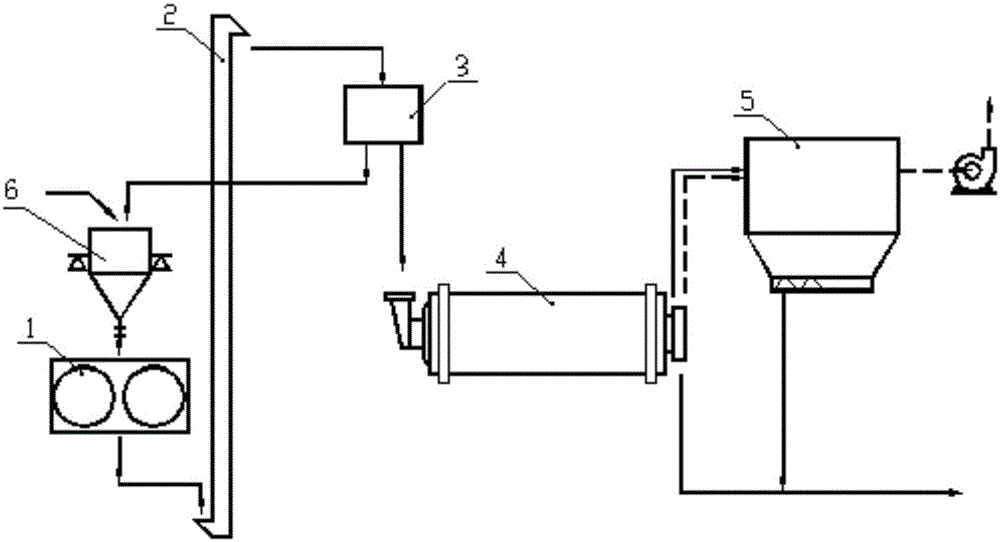

[0015] Referring to the accompanying drawings, the high-pressure and high-efficiency roller press grinding system with a screening device includes a roller press 1 and a ball mill 4. There is a weighing chamber 6 above the roller press 1, and the pressure pair of the hydraulic system of the roller press 1 is fed into the The material is extruded and crushed, and the material discharged from the outlet of the roller press 1 is sent to the mechanical screening device 3 through the elevator 2, and the particles smaller than the mesh diameter of the mechanical screening device 3 are sent to the ball mill 4, and after entering the ball mill 4, pass through The finished product is made by fine grinding and shaping. The discharge port of the ball mill 4 is connected to a dust collector 5 to collect dust, and the particles larger than the mesh aperture of the mechanical screening device 3 are circulated back to the weighing chamber 6. The roller press 1 is equipped with a side Edge ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com