Kitchen waste deep recycling treatment method

The technology of a kitchen waste and a treatment method, which is applied in the field of kitchen waste, can solve the problems such as difficulty in breeding and screening of black soldier flies, low crude oil yield, difficulty in realizing automation and large-scale breeding, etc. And the increase of labor cost, the uniform nutrient density, the effect of shortening the breeding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] S1. In-depth pretreatment: take 100t / d of food waste, and perform the following operations on the food waste:

[0041] Solid-liquid separation treatment: Pour 100t / d of kitchen waste into the unloading bin, which is connected to a U-shaped shaftless screw conveying device with an angle of 27° between the horizontal plane. The U-shaped shaftless screw conveying device includes a tank lining Plate and shaftless spiral body, the tank lining plate is provided with a round hole, the diameter of the round hole is 10mm, when the food waste is transported in the U-shaped shaftless spiral conveying tank, 30% of the liquid in the food waste passes through the tank The round holes in the liner flow into the filtrate tank, so that the liquid and solid in the food waste are separated, and the filtrate and solid food waste are obtained. The moisture content of the solid food waste is 85%; the solid food waste passes through the U-shaped shaftless The screw conveying device conveys to...

Embodiment 2

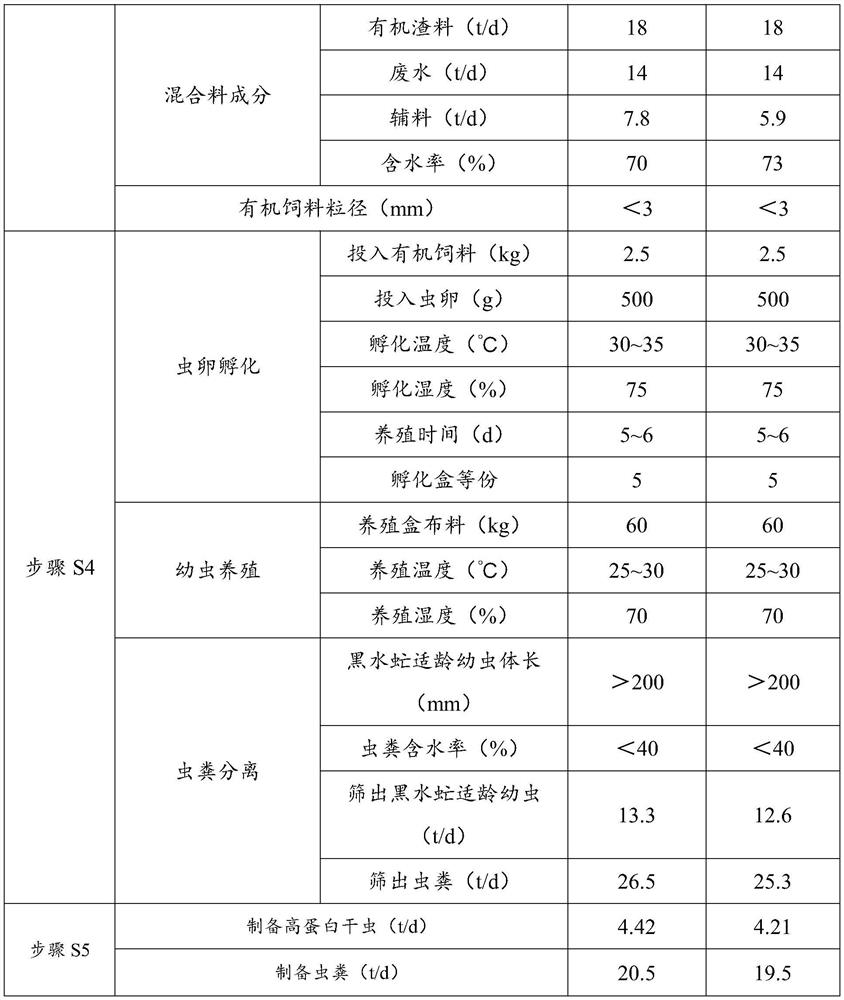

[0055] The difference between this embodiment and Example 1 is that in step S2, the oil content of the crude oil is 97.22%, the oil content of the waste water is 0.28%, the water content of the organic residue is 73%, and the oil content of the organic residue is 0.26%. , in step S3, the auxiliary material added in the mixture is the wheat bran of 5.9t / d, obtains the mixture of 37.9t / d altogether, adjusts the moisture content of mixture to 73%; In step S4 worm egg hatching step, worm, In the excrement separation step, the black soldier fly larvae sieved out at the outlet of the 6mm sieve frame was 12.6t / d, and the excrement sieved out at the outlet of the 3mm sieve frame was 25.3t / d; in step S5, the high-quality high-protein dry worms obtained were 4.21t / d, the obtained organic fertilizer is 19.5t / d.

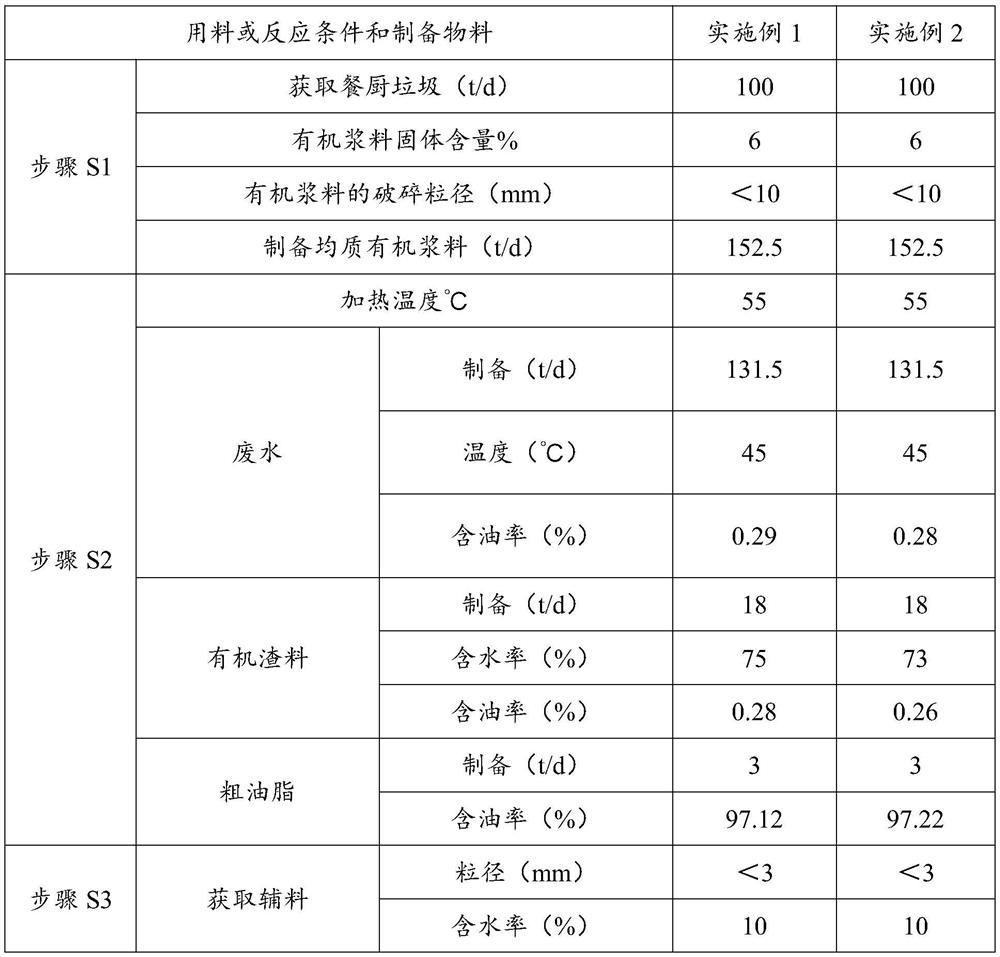

[0056] The materials, reaction conditions and prepared materials used in the embodiment 1-2 are shown in the table below,

[0057]

[0058]

[0059] In the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| body length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com