Mechanical screening type mixed material food racking machine and racking method thereof

A mixed material and mechanical sieve technology, which is applied to the types of packaging items, packaging, liquid materials, etc., can solve the problems of high equipment cost and maintenance cost, blockage of suction pump, mechanical pipeline blockage, etc., and achieve low equipment cost and maintenance cost , The structure and principle are simple, ensuring the effect of beauty and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

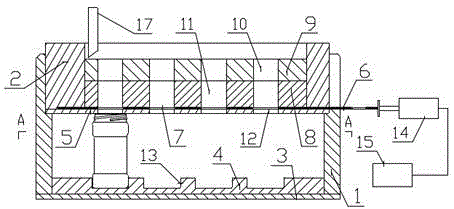

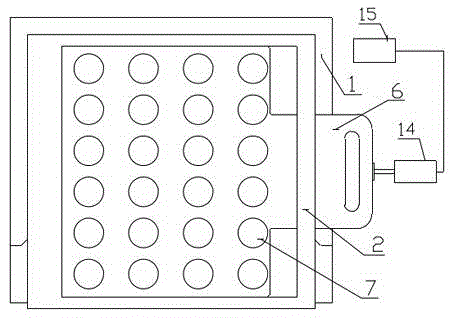

[0020] Example 1. A mechanical sieving type mixed food packaging machine, constituted as Figure 1-3 As shown, it includes a positioning frame 1, and the upper part of the positioning frame 1 is connected to the material distribution frame 2. The material distribution frame 2 includes a material distribution frame bottom plate 5, a switch plate 6 is arranged above the material distribution frame bottom plate 5, and a switch plate 6 is arranged above the There is a dividing hopper, which is arranged inside the dividing frame 2 with quantitative holes; the bottom plate 5 of the dividing frame is provided with a through hole 12; the switch plate 6 is provided with a switch hole 7 .

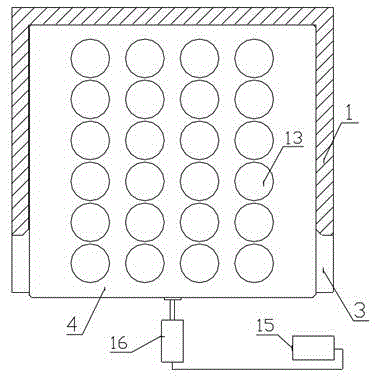

[0021] A positioning frame bottom plate 3 is provided at the lower part of the aforementioned positioning frame 1, a glass bottle support plate 4 is provided above the positioning frame bottom plate 3, and a glass bottle positioning hole 13 is provided on the glass bottle support plate 4.

[0022] The a...

Embodiment 2

[0025] Example 2. A mechanical sieving type mixed food packaging machine, composed as Figure 1-3 As shown, it includes a positioning frame 1, and the upper part of the positioning frame 1 is connected to the material distribution frame 2. The material distribution frame 2 includes a material distribution frame bottom plate 5, a switch plate 6 is arranged above the material distribution frame bottom plate 5, and a switch plate 6 is arranged above the There is a dividing hopper, which is arranged inside the dividing frame 2 with quantitative holes; the bottom plate 5 of the dividing frame is provided with a through hole 12; the switch plate 6 is provided with a switch hole 7 .

[0026] A positioning frame bottom plate 3 is provided at the lower part of the aforementioned positioning frame 1, a glass bottle support plate 4 is provided above the positioning frame bottom plate 3, and a glass bottle positioning hole 13 is provided on the glass bottle support plate 4.

[0027] The afor...

Embodiment 3

[0030] Example 3. A mechanical sieving type mixed food packaging machine, composed as Figure 1-3 As shown, it includes a positioning frame 1, and the upper part of the positioning frame 1 is connected to the material distribution frame 2. The material distribution frame 2 includes a material distribution frame bottom plate 5, and a switch board 6 is arranged above the material distribution frame bottom plate 5, and the switch board 6 is arranged above There is a dividing hopper, which is arranged inside the dividing frame 2 with quantitative holes; the bottom plate 5 of the dividing frame is provided with a through hole 12; the switch plate 6 is provided with a switch hole 7 .

[0031] A positioning frame bottom plate 3 is provided at the lower part of the aforementioned positioning frame 1, a glass bottle support plate 4 is provided above the positioning frame bottom plate 3, and a glass bottle positioning hole 13 is provided on the glass bottle support plate 4.

[0032] The af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com