A compound fertilizer mixing and stirring equipment

A technology for mixing and mixing fertilizers, which is applied to mixers, mixer accessories, mixers with rotary mixing devices, etc., can solve the problem of inability to control the mixing ratio of two fertilizer raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

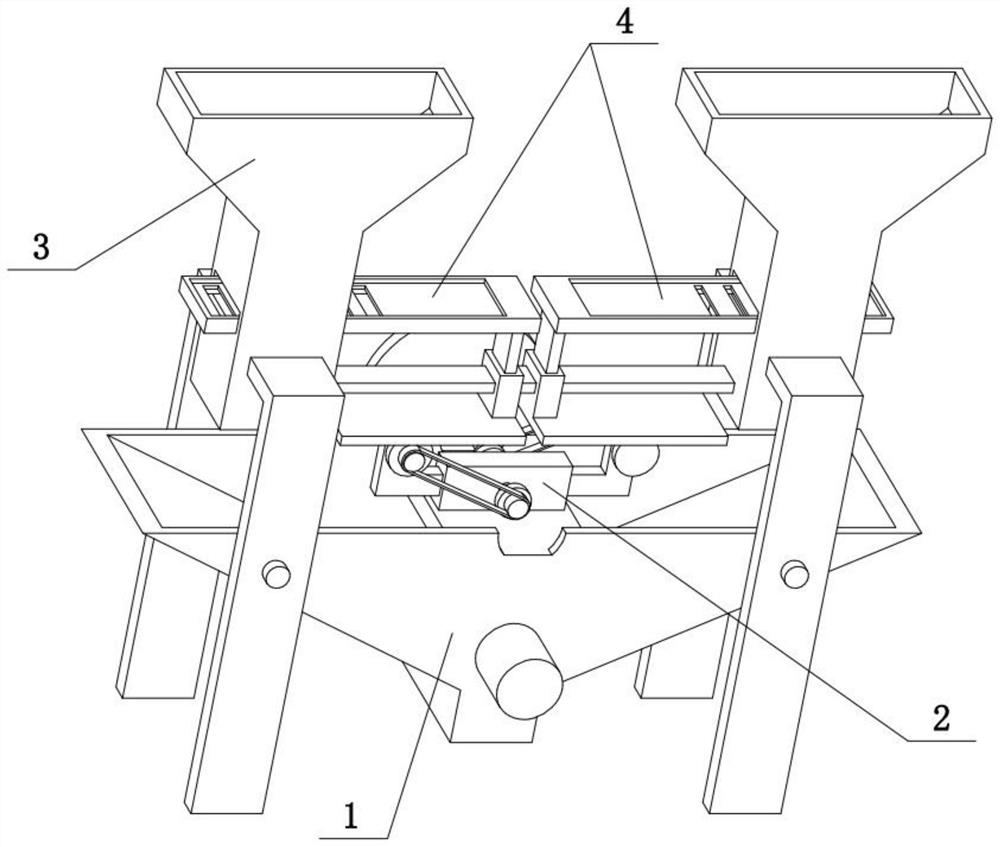

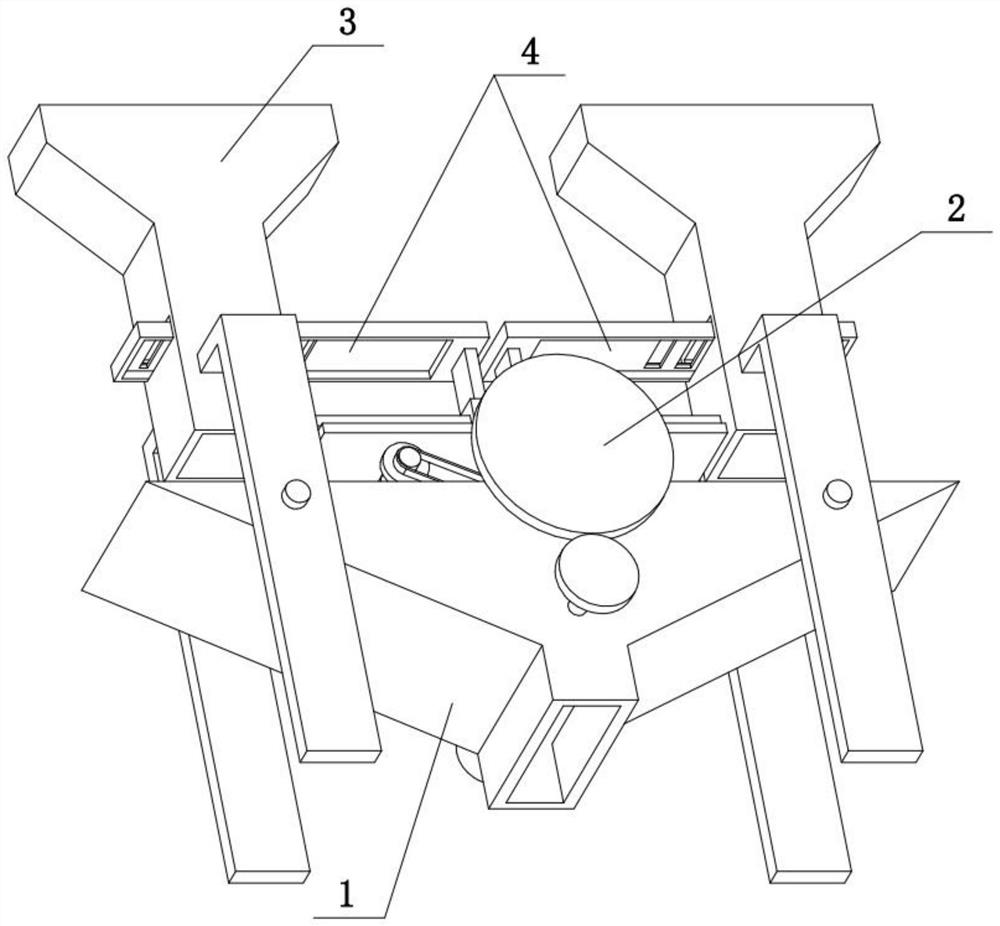

[0028] Combine below Figure 1-9 Describe this embodiment, the present invention relates to a kind of mixing equipment, more specifically a kind of compound fertilizer mixing and stirring equipment, including mixer 1, opening and closing control mechanism 2, fertilizer box 3 and opening and closing door 4, the present invention can By setting the area of different blanking holes 4-6 on the two blanking plates 4-5, the mixing ratio of the two fertilizer raw materials can be controlled, and when mixing is not required, the two bottom covers 4-1 are closed , at this time the stirring shaft 1-7 will also stop the stirring operation.

[0029] The opening and closing control mechanism 2 is fixedly connected to the upper end of the mixer 1, the rear end of the opening and closing control mechanism 2 is engaged with the mixer 1 for transmission, the fertilizer box 3 is fixedly connected to the upper end of the mixer 1, and the opening and closing control mechanism 2 is located at th...

specific Embodiment approach 2

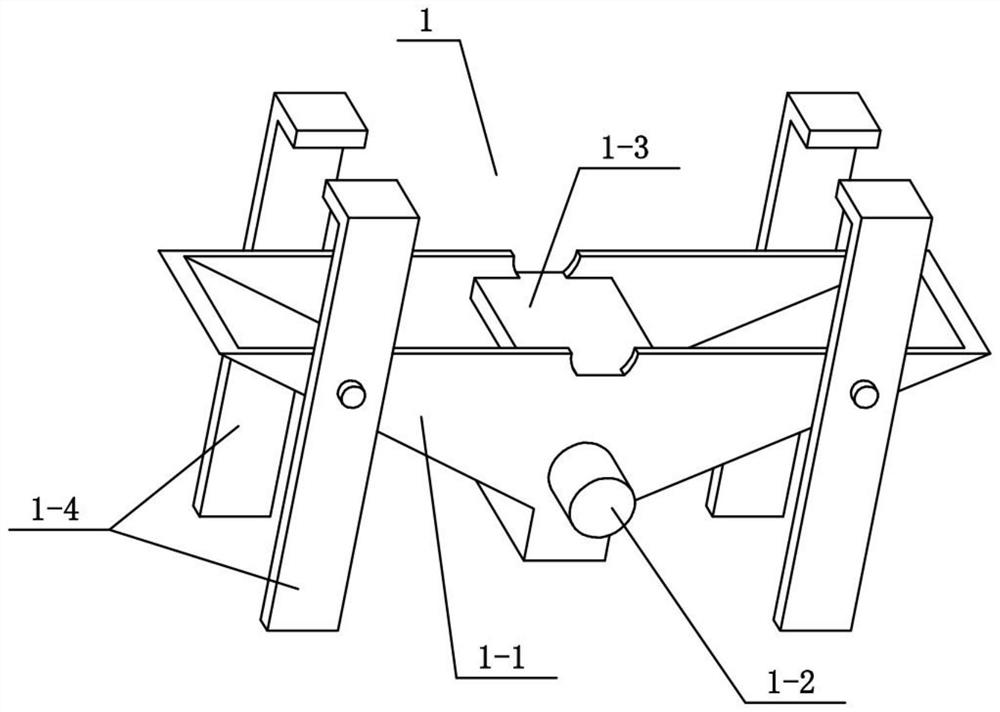

[0031] Combine below Figure 1-9 To illustrate this embodiment, the mixer 1 includes a triangular funnel 1-1, a motor I1-2, a middle support plate 1-3, a support rod 1-4, a discharge port 1-5, a pinion 1-6, a stirring The shaft 1-7 and the stirring rod 1-8, the triangular funnel 1-1 is an inverted triangular container, the lower end of the triangular funnel 1-1 is provided with a discharge port 1-5, and the motor I1-2 is fixedly connected to the bottom of the triangular funnel 1-1 At the front end, the output shaft of the motor I1-2 is fixedly connected with a stirring shaft 1-7, and the stirring shaft 1-7 is provided with a plurality of stirring rods 1-8, and the stirring shaft 1-7 and a plurality of stirring rods 1-8 are located at the outlet Above the feed port 1-5, the rear end of the stirring shaft 1-7 is fixedly connected with a pinion 1-6, the front and rear ends of the left end of the triangular funnel 1-1 are fixedly connected with a support rod 1-4, and the triangula...

specific Embodiment approach 3

[0033] Combine below Figure 1-9To illustrate this embodiment, the opening and closing control mechanism 2 includes a middle block 2-1, a side frame 2-2, a right friction wheel 2-3, a right shaft 2-4, a right pulley 2-5, a large gear 2-6, Rear axle rod 2-7, left friction wheel 2-8, left shaft 2-9, left pulley 2-10, middle pulley 2-11 and middle shaft 2-12, the middle end of middle piece 2-1 rotates and is connected with middle Axle 2-12, the front and rear ends of central axis 2-12 are all fixedly connected with middle pulley 2-11, the left and right ends of middle block 2-1 are all fixedly connected with side frame 2-2, the side frame 2-2 of right end The upper rotation is connected with the right shaft 2-4, and the front and rear ends of the right shaft 2-4 are fixedly connected with the right friction wheel 2-3, and the right friction wheel 2-3 at the rear end is fixedly connected with the right belt pulley 2-5, the right The belt pulley 2-5 and the middle pulley 2-11 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com