ZSM-5 molecular sieve modified catalyst as well as preparation method and application thereof

A ZSM-5 and catalyst technology, applied in the field of ZSM-5 molecular sieve modified catalyst, can solve the problems of difficult to obtain high-selectivity catalyst, high concentration of dilute ethanol solution, uneven molecular sieve crystal form, etc., so that the catalytic activity does not decrease. , The effect of stable catalyst activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

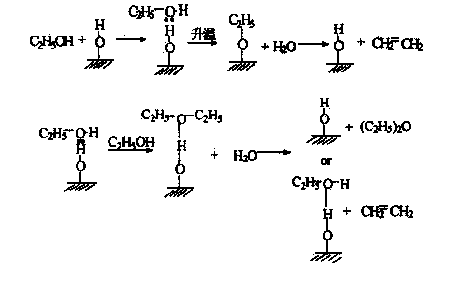

Method used

Image

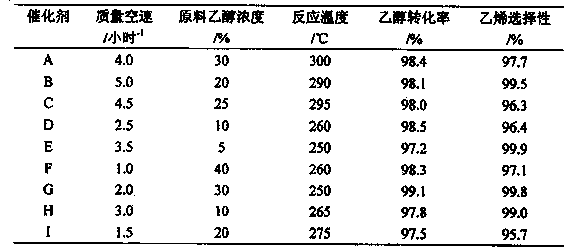

Examples

Embodiment 1

[0028] Embodiment 1, a ZSM-5 molecular sieve modified catalyst, the modified catalyst body has a porous crystal material composed of the following molar ratios: A1 2 o 3 : nSiO 2 , where the value of n is 15-150.

Embodiment 2

[0029] Embodiment 2, a ZSM-5 molecular sieve modified catalyst, the modified catalyst body has a porous crystal material composed of the following molar ratios: A1 2 o 3 : nSiO 2 , where the value of n is 20-60.

Embodiment 3

[0030] Example 3, in the ZSM-5 molecular sieve modified catalyst described in Example 1 or 2: the grain size of the porous crystal material is 0.5-10 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com