Catalyst for coupling catalytic pyrolysis of methanol and naphtha, preparation method and application

A catalytic cracking and naphtha technology, applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of low yield of ethylene + propylene, improve yield, inhibit hydrogen transfer and carbon deposition, The effect of improving the yield of diene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take by weighing 240 grams of solution containing 30.7 grams of phosphoric acid and impregnate 200 grams of hydrogen ZSM-5 molecular sieve (SiO 2 with Al 2 o 3 The silicon-aluminum ratio is 20), aged at room temperature for 2-24 hours, dried at 100-140°C for 12 hours, and fired at 550°C for 6 hours. Take the previous step to obtain 100.0 grams of modified ZSM-5 molecular sieves, 10.0 grams of SAPO-34 molecular sieves (SiO 2 with Al 2 o 3 The ratio of silicon to aluminum is 0.01), 40.0 grams of kaolin, 238.1 grams of aluminum sol (21.0% Al 2 o 3 ) and 212.0% water were mixed evenly to form a slurry, which was sprayed to obtain microspheres with a particle size of 10-200 μm, and then calcined at 600°C for 4 hours to obtain a fluidized bed microsphere catalyst. The specific catalyst composition can be seen in Table 2.

[0023] When the reaction temperature is 650°C, the space velocity of naphtha is 0.7h -1 , the weight ratio of methanol to naphtha is 1.0, and the pr...

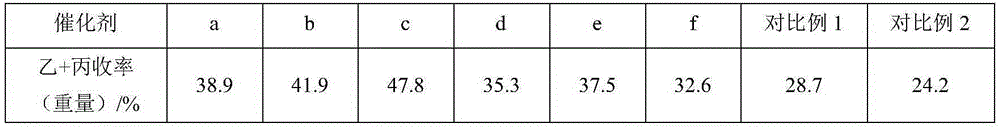

Embodiment 2-6

[0025] Catalysts b-f were prepared and evaluated according to the same preparation method, and the compositions and evaluation results of the catalysts can be seen in Table 3.

Embodiment 7-10

[0031] Using catalyst c, changing process conditions, the evaluation results obtained are listed in Table 4

[0032] Table 1

[0033] project data Density(20℃)kg / m3 704.6 Distillation Range Initial Distillation Range °C 40 Final boiling range °C 160 Saturated vapor pressure(20℃)kPa 50.2 Alkanes % (weight %) 65.18 Normal alkanes % in alkanes (weight %) >32.5 Cycloalkane % (weight %) 28.44 Olefin % (wt%) 0.17 Aromatics % (wt%) 6.21

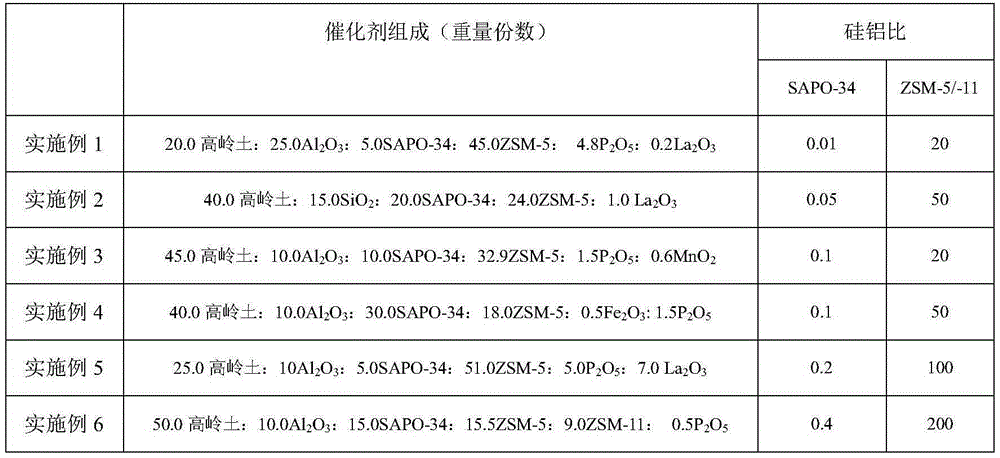

[0034] Table 2

[0035]

[0036]

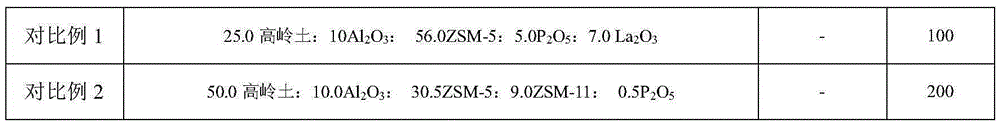

[0037] table 3

[0038]

[0039] Table 4

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com