MCM-22/ZSM-5 in-situ intergrowth methanol aromatization catalyst and preparation method of catalyst

A technology of MCM-22 and ZSM-5, applied in the field of methanol-to-aromatic catalysts, can solve problems such as low aromatization yield, and achieve the effects of increasing relative content, improving activity and reducing clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

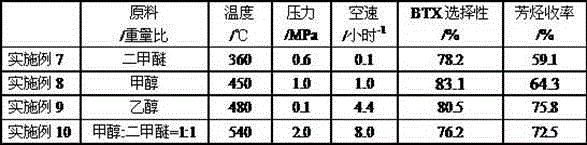

Examples

Embodiment 1

[0030] 140 grams of kaolin (55.3% SiO 2 , 42.5%Al 2 o 3 , 2.2% other oxides), 40 grams of ZSM-5 molecular sieve (the molar ratio of silica to alumina is 400), 50 grams of silica sol (40% SiO 2 ) and 370 grams of water were mixed evenly, and sprayed to obtain 20-200 μm pellets, which were roasted at 900°C for 4 hours to obtain spray microspheres ZQ1 with a particle size of 10-200 μm.

[0031] Get 100 grams of spray microspheres ZQ1, 0.65 grams of sodium hydroxide, 0.63 grams of aluminum nitrate, 1.7 grams of hexamethyleneimine and 500 grams of water and mix evenly (in the composition of this mixture, silicon oxide in kaolin is removed, and the remaining raw materials The ratio of silica to alumina is 200), and transferred to a closed reactor for crystallization at 120°C for 120 hours. After crystallization, the product was washed, dried at 120°C for 4 hours, and calcined at 550°C for 8 hours to obtain sodium molecular sieve microspheres MZQ1. Sodium-type microspheres were e...

Embodiment 2

[0036] 60 grams of kaolin, 120 grams of ZSM-5 molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 75), 20 grams of white carbon black (99.0% SiO 2 ) and 500 grams of water were mixed evenly, and sprayed to obtain 10-200 μm pellets, which were roasted at 1000°C for 4 hours to obtain spray microspheres ZQ2 with a particle size of 10-200 μm.

[0037] Get 100 grams of spray microspheres ZQ2, 2.2 grams of sodium hydroxide, 2.96 grams of aluminum sulfate, 20 grams of hexamethyleneimine and 500 grams of water and mix well (in the composition of this mixture, silicon oxide in kaolin is removed, and the remaining raw materials The ratio of silicon dioxide to aluminum oxide is 75), and transferred to a closed reactor for crystallization at 120°C for 120 hours. After crystallization, the product was washed, dried at 120°C for 4 hours, and calcined at 550°C for 8 hours to obtain sodium molecular sieve microspheres MZQ1. Sodium-type microspheres were exchanged with 1 mo...

Embodiment 3

[0041] Mix 40 grams of kaolin, 350 grams of silica sol, 20 grams of ZSM-5 molecular sieve (the molar ratio of silicon oxide to aluminum oxide is 20), and 300 grams of water, spray molding to obtain 10-200 μm pellets, and roast at 950 ° C After 4 hours, spray microspheres ZQ3 with a particle size of 10-200 μm were obtained.

[0042] Get 100 grams of spray microspheres ZQ3, 51.6 grams of sodium hydroxide, 28.2 grams of aluminum chloride, 200 grams of hexamethyleneimine and 5000 grams of water and mix them evenly (in this mixture, remove the silicon oxide in kaolin, and the rest of the raw materials The ratio of silica to alumina is 20), and transferred to a closed reactor for crystallization at 120°C for 120 hours. After crystallization, the product was washed, dried at 120°C for 4 hours, and calcined at 550°C for 8 hours to obtain sodium molecular sieve microspheres MZQ1. Sodium-type microspheres were exchanged with 1 mol / L ammonium nitrate solution, washed, dried at 120°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com