Heavy oil catalytic cracking catalyst

A cracking catalyst, heavy oil catalysis technology, applied in catalytic cracking, physical/chemical process catalyst, molecular sieve catalyst and other directions, can solve problems such as low liquid yield, and achieve the effects of less dosage, improved conversion, and improved propylene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

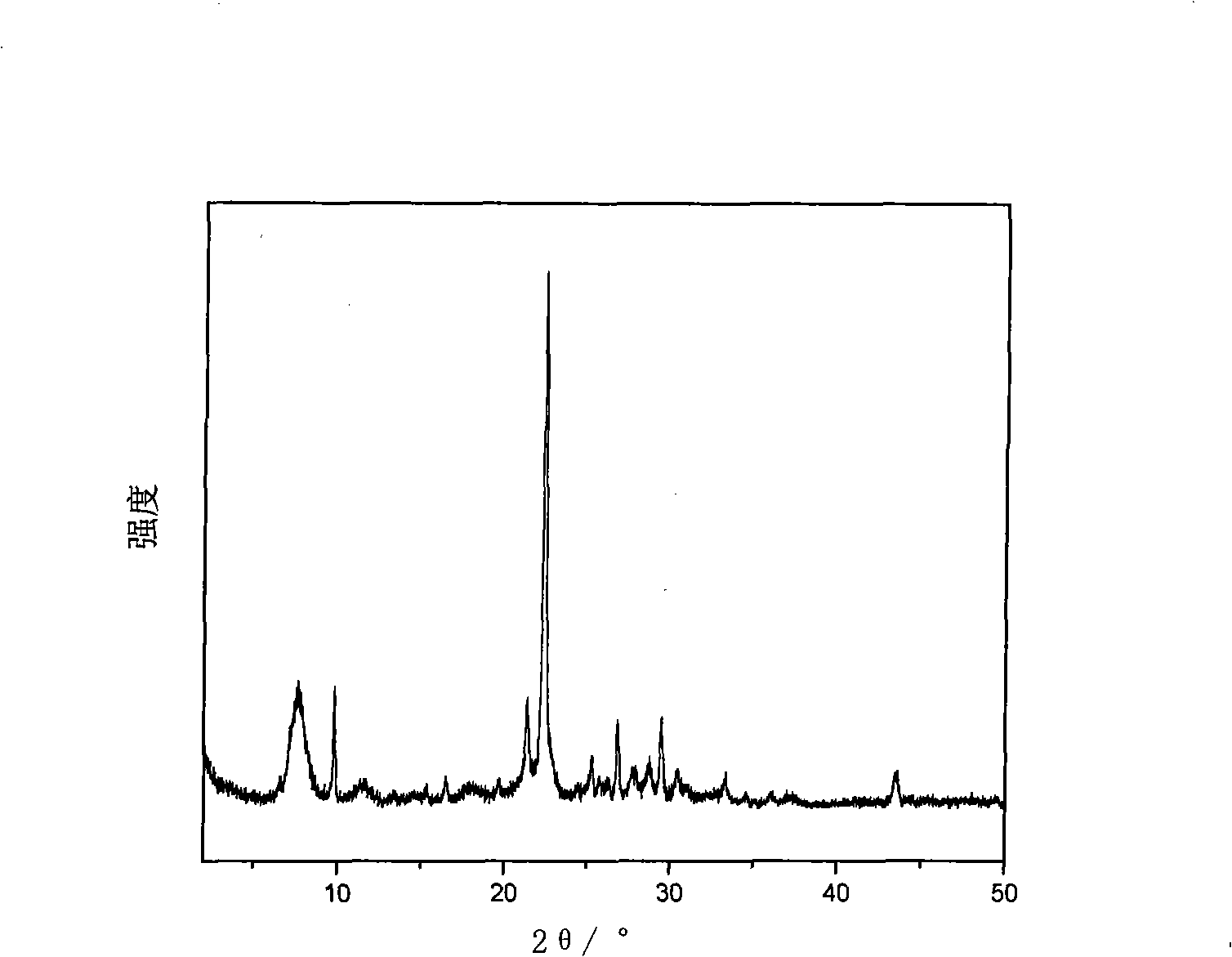

[0018] Example 1: Weigh 10.8 grams (0.18mol) of silica gel, 4.08 grams (0.050mol) of sodium metaaluminate, 5.67 grams (0.027mol) of tetraethylammonium bromide, 0.44 grams of beta seed crystals, and add 3.6 grams of sodium hydroxide (0.09mol) control OH - ratio, put it into a mixer for mechanical mixing, after fully stirring, put the mixture on the support, feed water vapor, maintain the system temperature at 130°C to start crystallization, the crystallization time is 4 days, and you can get beta-mercerized co- Crystal molecular sieve, XRD pattern see figure 1 .

Embodiment 2

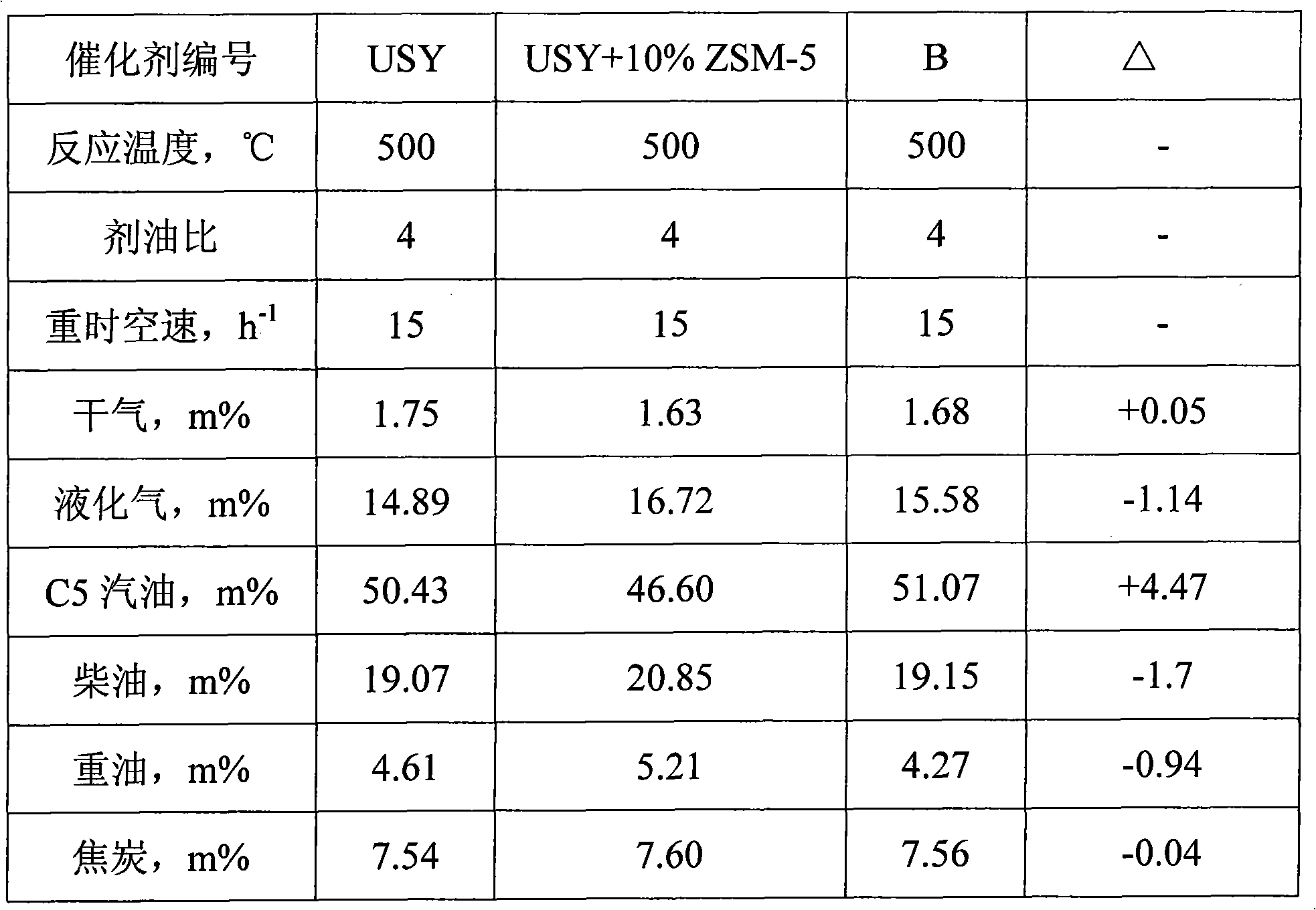

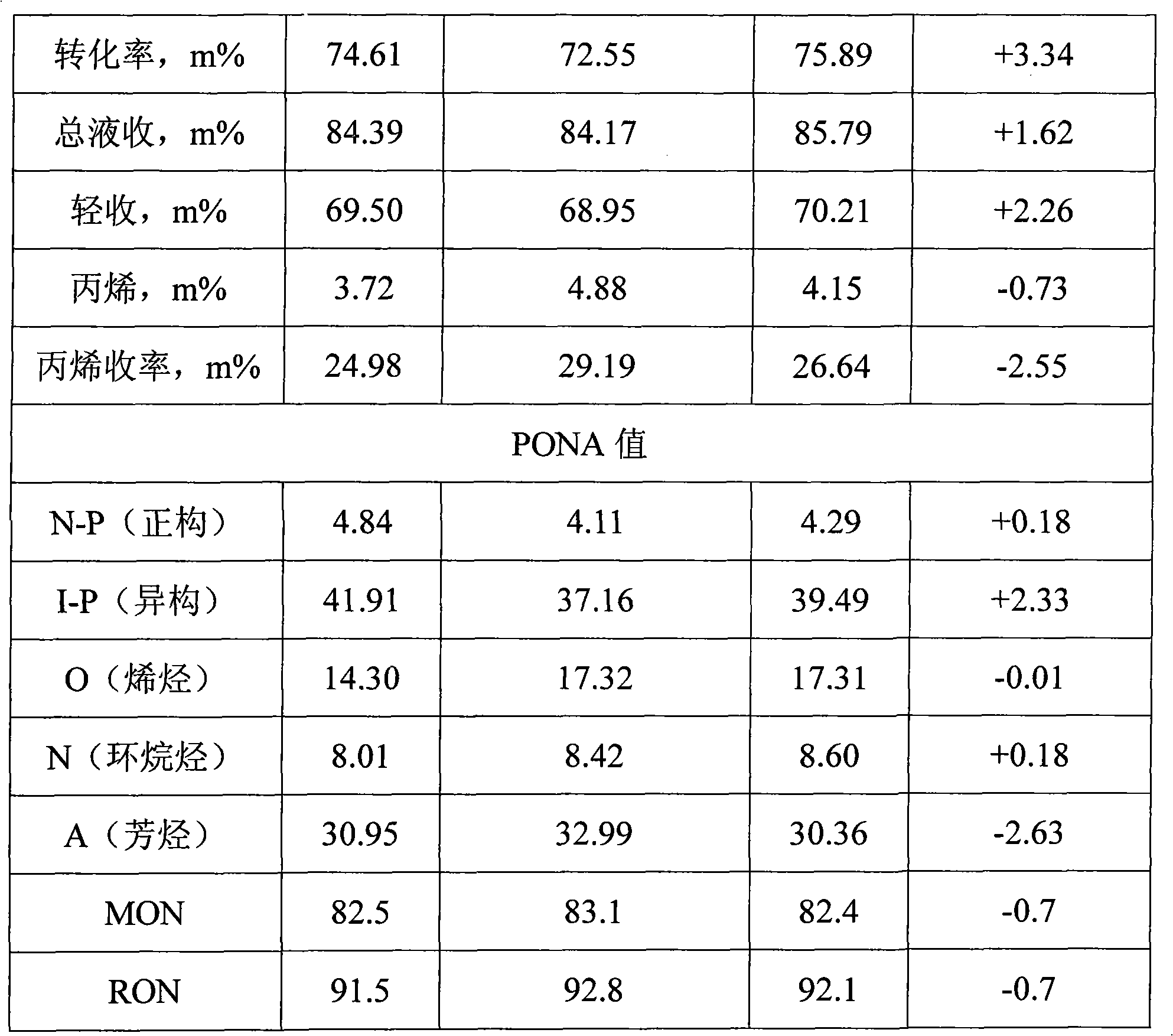

[0019] Example 2: The eutectic molecular sieve prepared in Example 1 is conventionally modified, that is, the original powder of the eutectic molecular sieve that removes the template is replaced with 1mol / L NH 4 NO 3 The solutions were mixed in a three-necked flask, heated to 100°C in a heating mantle and stirred for 4 hours, washed, dried, and roasted to obtain hydrogen-type molecular sieves, so that the content of sodium oxide was lower than 0.1%, and the prepared hydrogen-type molecular sieves were heated at 800°C, Aged with 100% water vapor for 10 hours to obtain additive beta-mercerized eutectic molecular sieve A. Prepare catalyst B of the present invention by 35% USY type molecular sieve, 10% molecular sieve A, 20% acidified pseudo-boehmite, 10% aluminum sol binding agent, 25% kaolin, its preparation method is first The kaolin and pseudo-boehmite are fully mixed uniformly, and after acidification treatment, they are fully mixed with molecular sieves and binders, and fi...

Embodiment 3

[0027]Example 3: The molecular sieve A prepared in Example 1 was routinely modified to obtain a hydrogen-type molecular sieve, so that the sodium oxide content was lower than 0.1%, and the prepared catalyst was aged at 800° C. with 100% steam for 10 hours to obtain Agent beta mixed crystal molecular sieve A. Prepare catalyst C provided by the invention by 25% USY type molecular sieve, 20% beta-mercerized eutectic molecular sieve A, 20% acidified pseudo-boehmite, 10% aluminum sol binder, 25% kaolin . Its preparation method is to mix kaolin and pseudo-boehmite fully and uniformly first, and after acidification treatment, then fully mix with molecular sieve and binder, and finally spray-dry the obtained slurry into particles with a diameter of 40-150 microns and Roasting, obtains the catalyst provided by the invention. The drying temperature is 120° C., the firing temperature is 500° C., and the firing time is 1.5 hours. Catalyst C 2 Pretreatment with 100% steam for 10 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com