Method for improving rate of recovery of floatation of rutile

A flotation recovery and roughing technology, applied in the field of rutile beneficiation, can solve the problems of high production cost and large consumption of collectors, and achieve the effects of low cost of chemicals, reduced cost of beneficiation agents, and reduced consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

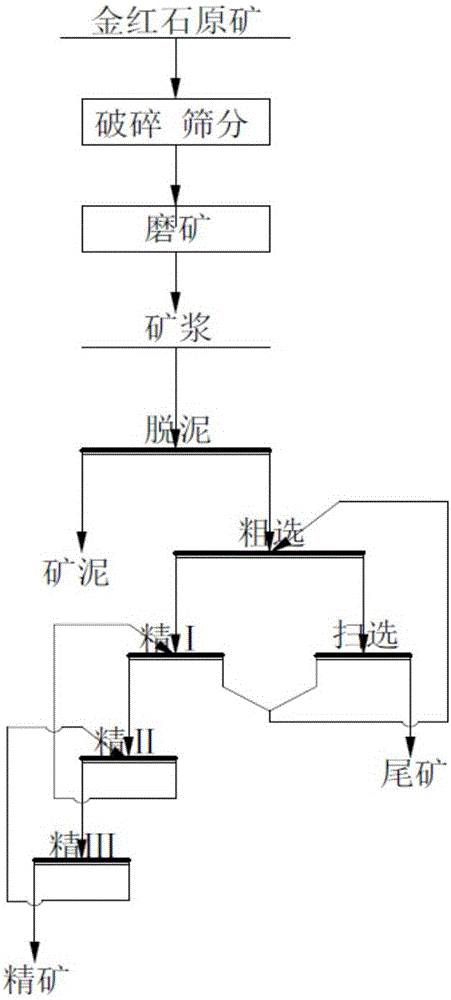

Image

Examples

Embodiment 1

[0032]A rutile mine in Hubei is used as the rutile raw ore, and the rutile content in the rutile raw ore is 2.24%. The main titanium-containing minerals in this ore are rutile, a small amount of ilmenite and sphene, other metal oxide minerals include a small amount of limonite, hematite and magnetite, and only trace pyrite is the sulfide; the gangue minerals are mainly Hornblende, followed by garnet, sodium mica, epidote, feldspar, chlorite, clay and quartz etc. The embedded particle size of rutile has a wide distribution, and the particle size is extremely uneven, but it is mainly concentrated in 0.01-0.32mm. The intercalation relationship between rutile and gangue minerals is relatively complicated. Most rutiles are distributed in gangue minerals such as hornblende, garnet, and muscovite in the form of disseminated unequal grains and disseminated fine grains. The grain size of these rutiles is extremely uneven. , belongs to the primary refractory rutile mine in my country. ...

Embodiment 2

[0034] A certain rutile mine in Shaanxi is used as the raw rutile ore, and the rutile content in the raw rutile ore is 2.49%. The main titanium-containing minerals in this ore are rutile, a small amount of titanite, ilmenite and anatase, and other metal oxide minerals include a small amount of limonite, hematite and magnetite, and only trace pyrite is the sulfide; The stone minerals are mainly hornblende, followed by biotite, plagioclase, calcite, dolomite and quartz. The distribution of rutile mosaic particle size is wide, and the particle size is extremely uneven, but it is mainly concentrated in 0.05-0.22mm. The intercalation relationship between rutile and gangue minerals is relatively complicated. Most rutiles are distributed in gangue minerals such as hornblende, biotite, and calcite in the form of disseminated unequal grains and disseminated fine grains. The grain size of these rutiles is extremely uneven. It belongs to the refractory rutile mine in my country. The raw...

Embodiment 3

[0036] A rutile mine in Hubei is used as the rutile raw ore, and the rutile content in the rutile raw ore is 2.61%. The main titanium-containing minerals in this ore are rutile, a small amount of ilmenite and sphene, other metal oxide minerals include a small amount of limonite, hematite and magnetite, and only trace pyrite is the sulfide; the gangue minerals are mainly Hornblende, followed by garnet, sodium mica, epidote, feldspar, chlorite, clay and quartz etc. The embedded particle size of rutile has a wide distribution, and the particle size is extremely uneven, but it is mainly concentrated in 0.01-0.32mm. The intercalation relationship between rutile and gangue minerals is relatively complicated. Most rutiles are distributed in gangue minerals such as hornblende, garnet, and muscovite in the form of disseminated unequal grains and disseminated fine grains. The grain size of these rutiles is extremely uneven. , belongs to the primary refractory rutile mine in my country. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com