Method for extracting lycopene from tomato pomace

A tomato pomace, lycopene technology, applied in the direction of bulk chemical production, fermentation, etc., can solve the problem of unrestricted pectinase and cellulase activity, yield and purity, unsatisfactory operability, and restrictions on tomato The widespread use of erythromycin and other issues, to achieve the effect of improving utilization and added value, important social significance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

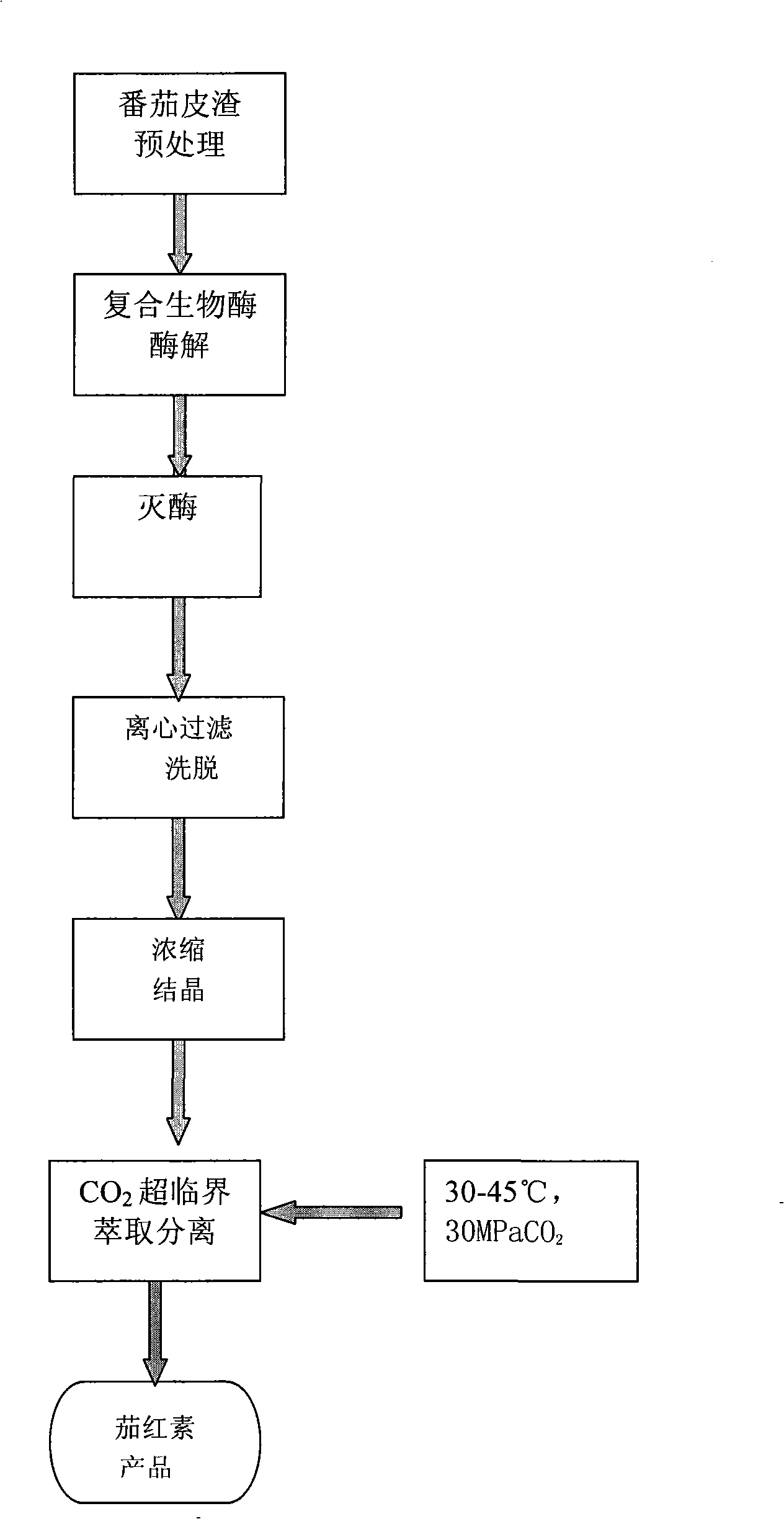

Method used

Image

Examples

Embodiment 1

[0023] Compound biological enzyme ratio (neutral protease, neutral cellulase and alkaline pectinase by weight ratio is 0.9:1:1.1)

[0024] Pour 10Kg of tomato peel residue into a 50L reaction container, add 20Kg of deionized water, and adjust the pH to 7.5; stir and heat to 50°C, add 5g of compound biological enzyme to react for 6 hours; then inactivate the enzyme at 70°C for 12 minutes; Centrifuge dehydration to obtain the enrichment, elute with alcohol, cool to 4°C to concentrate and crystallize, and obtain 0.82Kg of crude lycopene with a content of 11%; 2 Supercritical extraction and separation yielded 82 g of 95% lycopene crystals.

Embodiment 2

[0026] Compound biological enzyme ratio (neutral protease, neutral cellulase and alkaline pectinase in a weight ratio of 1:1:1)

[0027] Pour 20Kg of tomato skin residue into a 100L reaction container, add 60Kg of deionized water, and adjust the pH to 8.5; stir and heat to 55°C, add 20g of compound biological enzyme to react for 5 hours; then inactivate the enzyme at 72°C for 12 minutes; Centrifuge dehydration to obtain the enriched product, elute with alcohol, cool to 4°C to concentrate and crystallize, and obtain 1.72Kg of crude lycopene with a content of 10.5%; 2 Supercritical extraction and separation obtained 160 g of 95.5% lycopene crystals.

Embodiment 3

[0029] Compound biological enzyme ratio (neutral protease, neutral cellulase and alkaline pectinase by weight ratio is 1:1.1:0.9)

[0030] Pour 10Kg of tomato skin residue into a 100L reaction container, add 50Kg of deionized water, and adjust the pH to 9.0; stir and heat to 60°C, add 15g of compound biological enzyme to react for 4 hours; then inactivate the enzyme at 75°C for 10 minutes; Centrifuge dehydration to obtain the enrichment, elute with alcohol, cool to 4°C to concentrate and crystallize, and obtain 0.87Kg of crude lycopene with a content of 10%; 2 Supercritical extraction and separation yielded 85 g of 95% lycopene crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com